Cooling control system and method for power battery of hybrid electric vehicle

A cooling control technology for hybrid electric vehicles, applied in battery temperature control, battery/fuel cell control devices, electric vehicles, etc., can solve problems such as difficult to meet cooling requirements

Active Publication Date: 2017-10-03

CHONGQING CHANGAN AUTOMOBILE CO LTD

View PDF9 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The operating conditions of the car are complex and changeable, which has a great impact on the cooling control of the battery pack. For example, the ambient temperature of the battery is an important factor affecting the heating and cooling of the battery. The power battery has a high requirement for the working environment. It is difficult for one refrigeration method to meet the cooling needs under various working conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

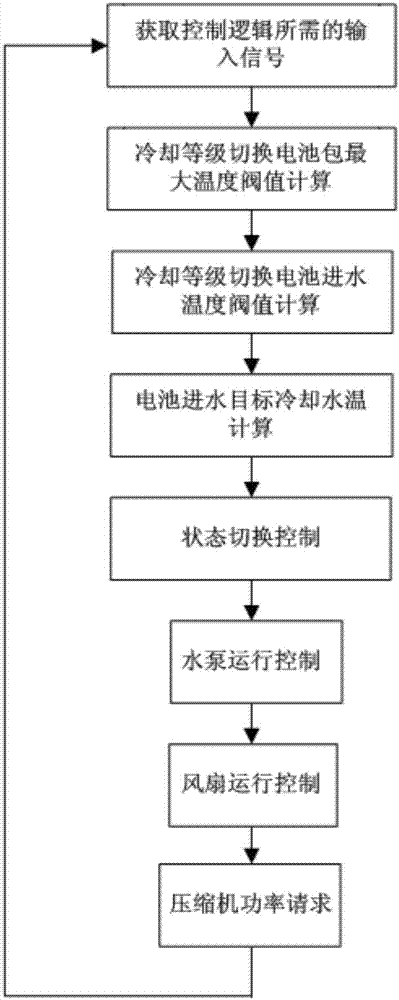

[0131] The above specific flow is just a specific embodiment. When the priority of the judgment condition changes, referring to the above embodiment, more kinds of specific control flow can be correspondingly changed, which will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

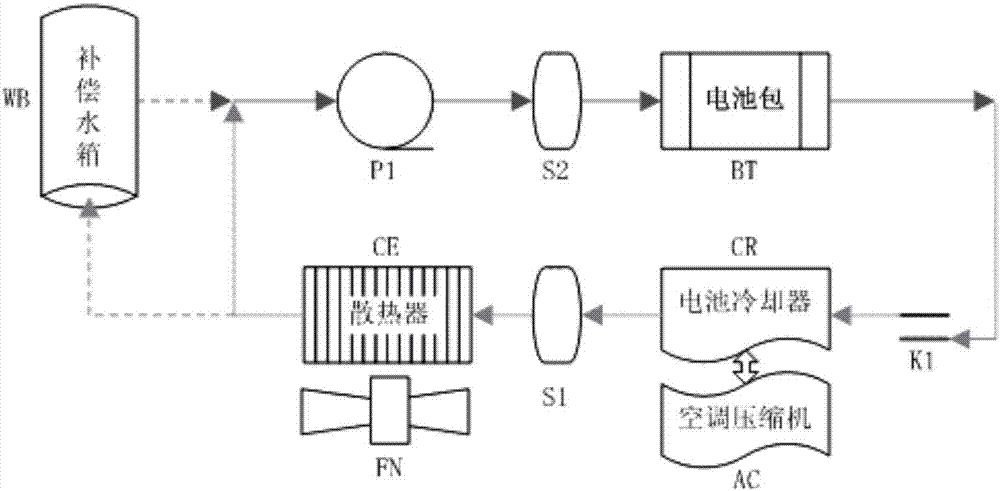

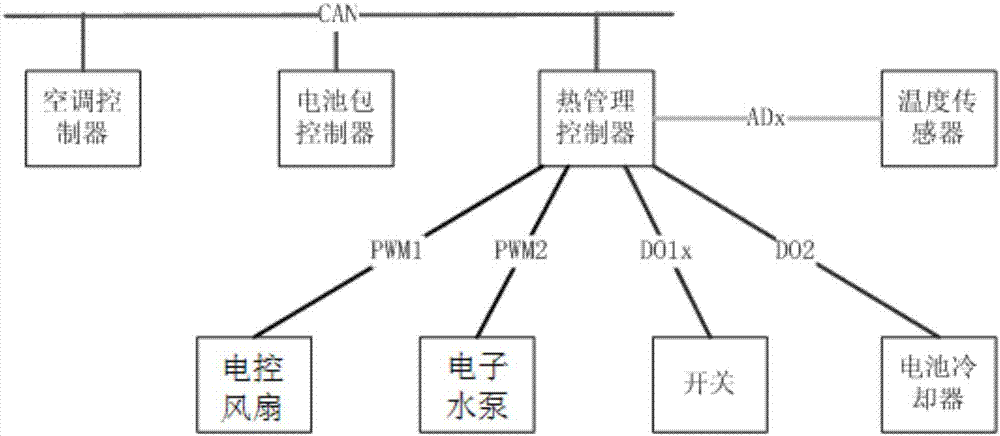

The invention relates to a cooling control system for a power battery of a hybrid electric vehicle. By adoption of the cooling control system, influence of the vehicle operation working condition to the battery pack cooling is analyzed and evaluated comprehensively; and air cooling, water cooling and compressor refrigerating are controlled to realize in-time and effective cooling by virtue of integration of the working environment temperature of the battery pack, the residual electric quantity of the battery and the battery output power according to different requirements in battery cooling, so that compatibility and part sharing with the conventional automobile thermal management system are realized, and power consumption management can be realized easily. The invention also relates to a cooling control method for the power battery of the hybrid electric vehicle; the cooling control method comprises three cooling modes, including a natural water cooling mode, a fan water cooling mode and a forced cooling mode, so that requirements of different levels in battery pack cooling can be satisfied, stable transition of different cooling modes can be realized, and energy-saving design of the system is also taken into consideration.

Description

technical field [0001] The invention relates to a temperature control technology of a power battery, in particular to a cooling control system and method for a power battery of a hybrid electric vehicle. Background technique [0002] The power battery will generate heat during charging and discharging. If the heat cannot be dissipated in time under high temperature conditions, it will not only affect its working efficiency, but also affect its service life, and even cause safety hazards. [0003] The power battery thermal management system of hybrid electric vehicles uses air cooling, water cooling or oil cooling to cool the battery pack. The air cooling method does not require complex pipeline layout, but the heat dissipation capacity is limited, the heat dissipation is uneven, and the design requirements for the overall structure of the engine compartment are high. The oil cooling method can dissipate heat evenly, and the heat dissipation capacity is also good, but the de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M10/613H01M10/625H01M10/635H01M10/65H01M10/6567B60L11/18

CPCB60L58/26H01M10/613H01M10/625H01M10/635H01M10/65H01M10/6567Y02E60/10Y02T10/70

Inventor 裴文龙严臣树甘国超单玉梅陈兴富周波

Owner CHONGQING CHANGAN AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com