Drum-type washer/dryer

a drum-type washer and dryer technology, which is applied in the direction of washing machines with receptacles, other washing machines, textiles and papermaking, etc., can solve the problems of poor dry performance, reduced heat exchange efficiency at the evaporator and the condenser of the heat pump, and complex configuration of the recirculation air passageway as a whole, so as to improve heat exchange efficiency, increase the amount of recirculation airflow, and avoid the effect of conduit resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]A detailed description will be given on the present invention with reference to the accompanying drawings.

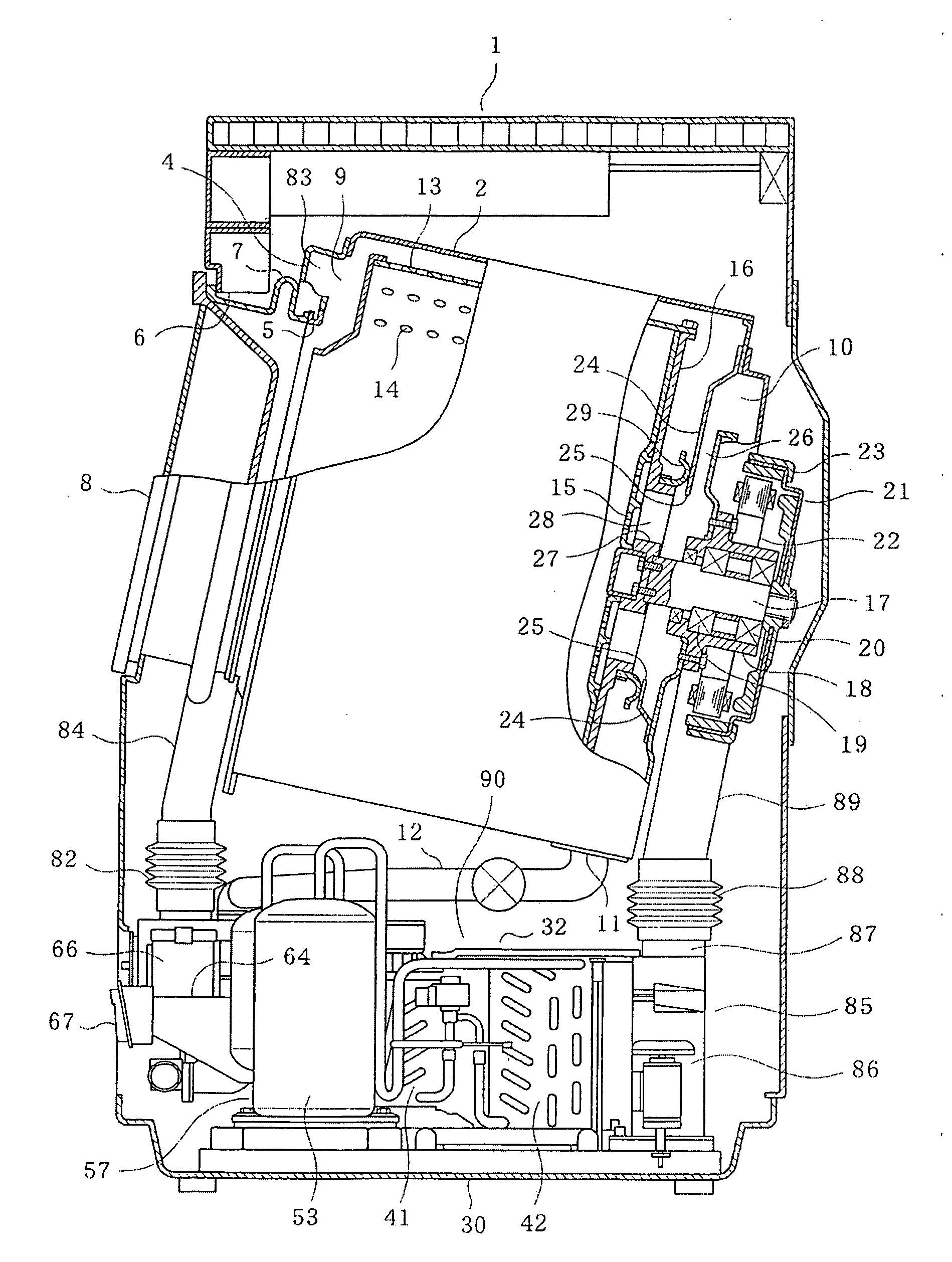

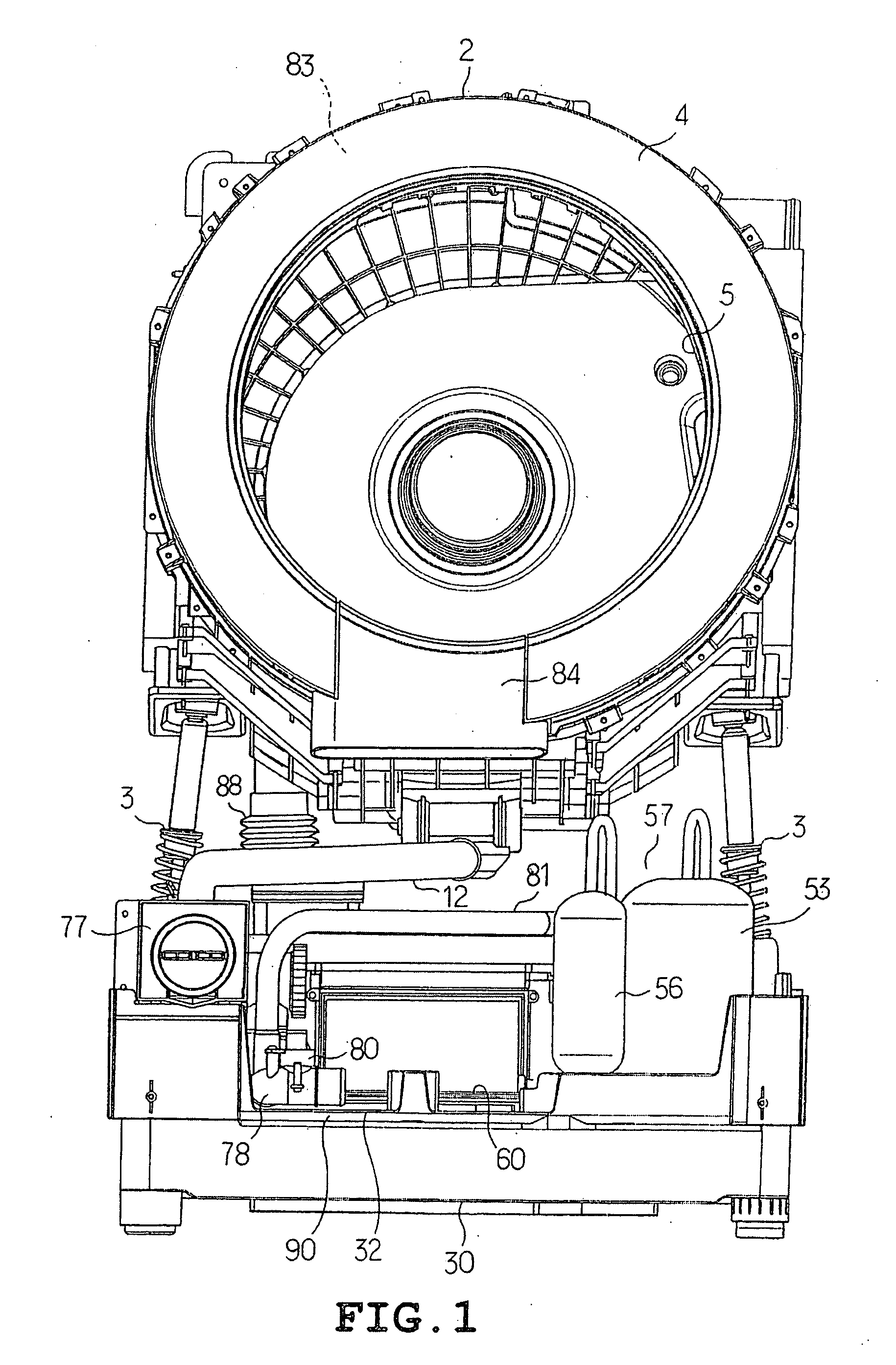

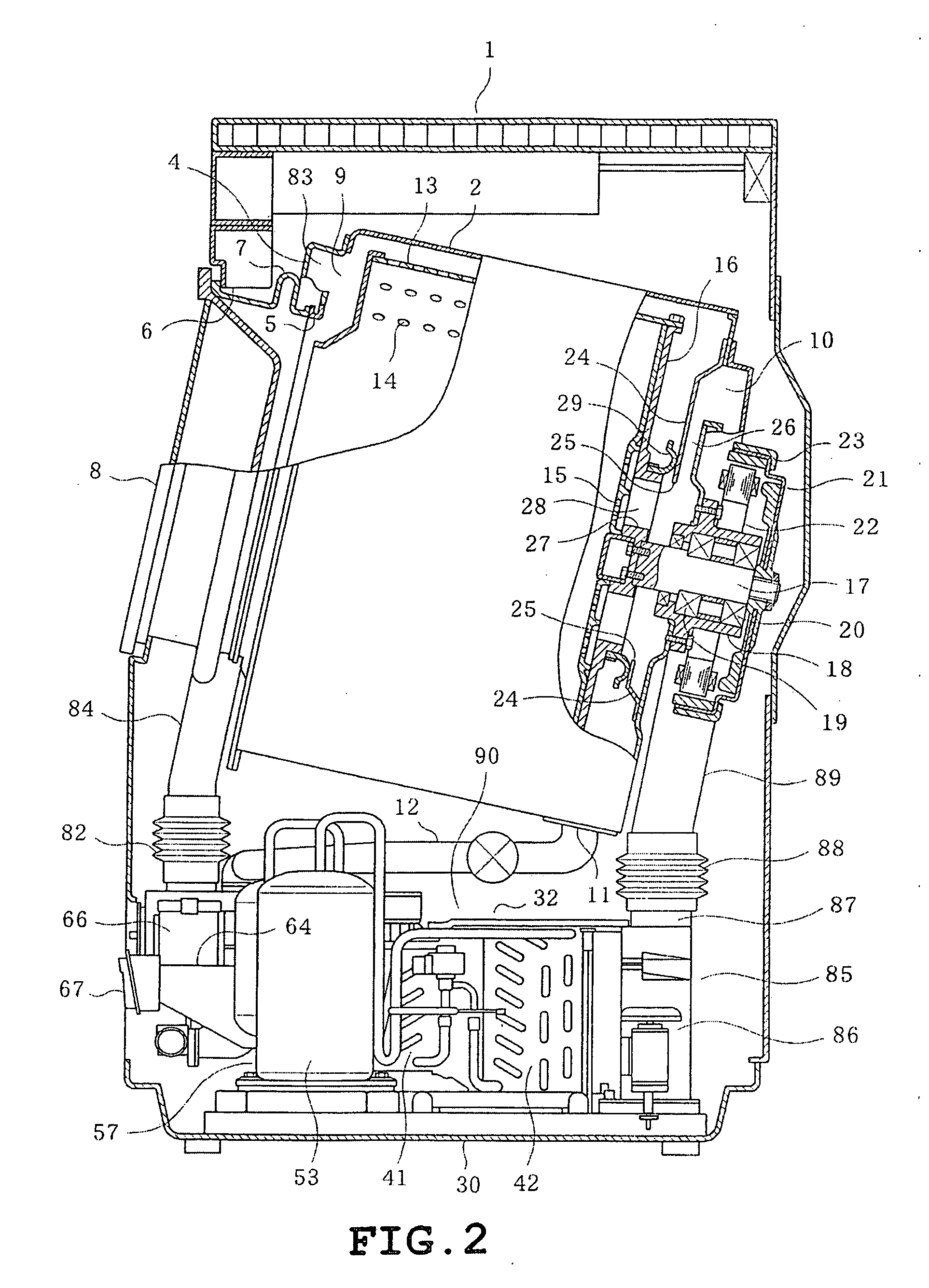

[0023]FIGS. 1 to 10 illustrate one exemplary embodiment of the present invention.

[0024]FIG. 2 illustrates the overall configuration of the drum-type washer / dryer. A cylindrical water tub 2 is supported by a pair of left and right suspensions 3 (refer to FIG. 1) inside a cabinet 1 constituting the exterior housing of the drum-type washer / dryer. The water tub 2 is laterally disposed with its axis running in the longitudinal direction (left and right direction in FIG. 2) and being slightly inclined upward (inclined leftwardly upward in FIG. 2). Also, an annular water tub cover 4 having an opening 5 in its substantial center is mounted on the front end of the water tub 2. An opening 6 is provided on the front surface of the cabinet 1 for loading and unloading of laundry. The opening 5 of the water tub cover 4 communicates with the opening 6 by bellows 7. An openable / closable d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com