Method for preparing low carbon olefins from oxygen-containing compound by conversion

A low-carbon olefin and production method technology, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, ethylene production, hydrocarbon cracking, etc., can solve the problem of low yield of low-carbon olefins, many by-products of C4 and above hydrocarbons, etc. problems, achieve the effect of reducing separation cost, reducing the generation of by-products, and reducing energy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

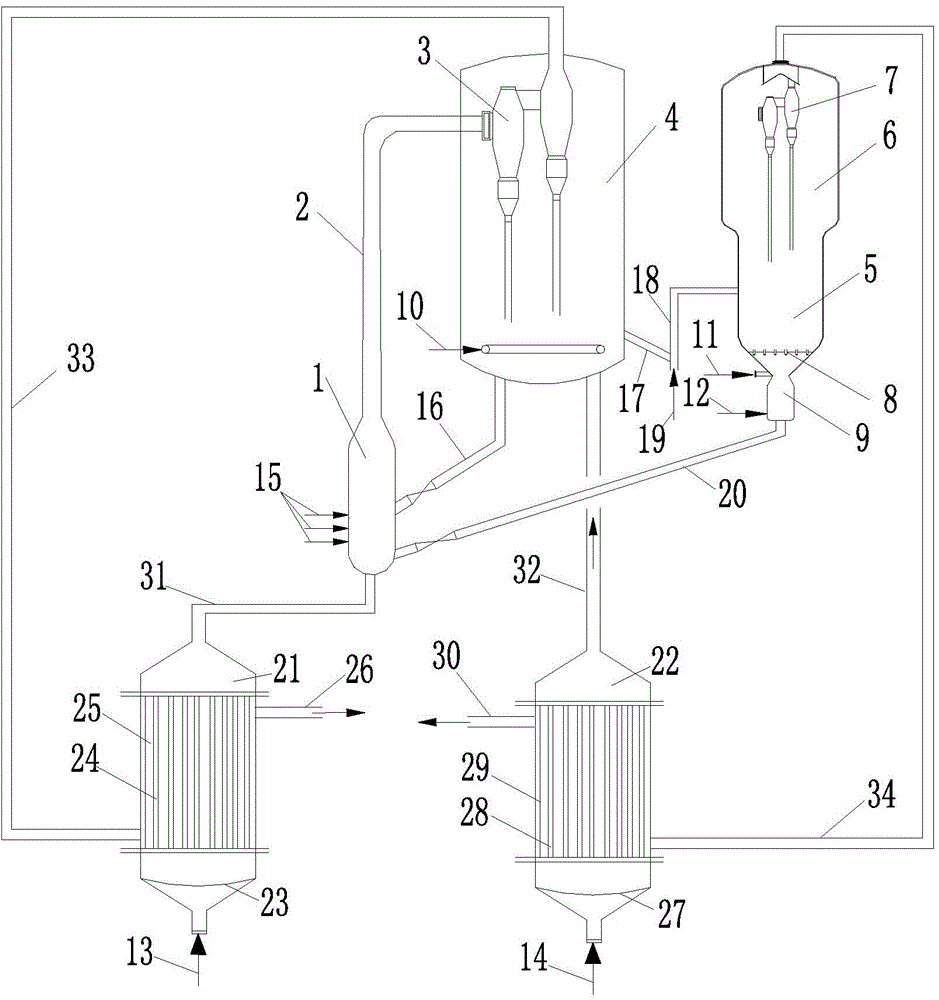

[0018] in such as figure 1 In the reaction device shown, the fluidized bed reactor adopts a fast fluidized bed, the catalyst adopts SAPO-34, the reaction temperature is 500°C, the reaction pressure is 0.1MPa in gauge pressure, and the gas linear velocity in the reactor is 1.5m / s; tube side of the prereactor is filled with γ-Al 2 o 3 / SiO 2 Catalyst, the raw material is methanol, the raw material inlet temperature is 120°C, the reaction pressure is 0.4MPa in gauge pressure, and the weight hourly space velocity is 4h -1 ; The tube side of the fixed bed reactor is filled with ZSM-5 catalyst, carbon four and above hydrocarbons (C4 + ) mixed feed (the stock material comes from the mixed hydrocarbon cycle of the MTO product gas separation system), the reactor inlet temperature is 600 ° C, the reaction pressure is 0.15 MPa in gauge pressure, C4 + The weight hourly space velocity is 4h -1 . The regenerator adopts a turbulent flow bed, the regeneration medium is air, the regener...

Embodiment 2~5

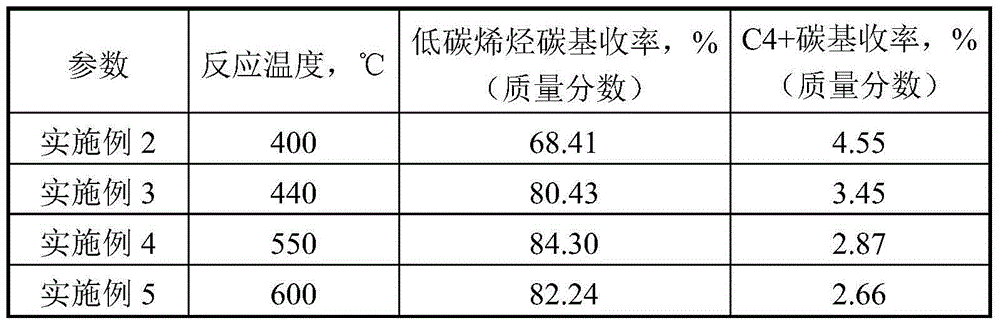

[0020] According to the conditions described in Example 1, only the reaction temperature of the fluidized bed reactor was changed, and the experimental results are shown in Table 1.

[0021] Table 1

[0022]

Embodiment 6~7

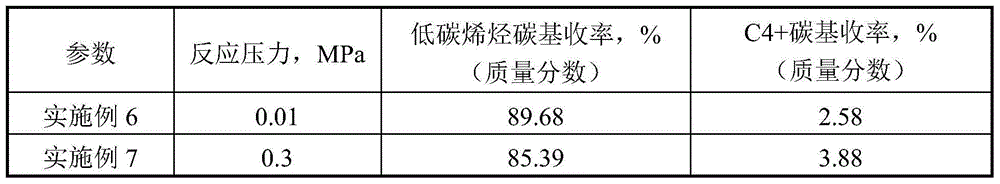

[0024] According to the conditions described in Example 1, only the reaction pressure of the fluidized bed reactor was changed, and the experimental results are shown in Table 2.

[0025] Table 2

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com