High-efficiency heat-integrated moving-bed methanol-to-hydrocarbon process

A methanol-to-hydrocarbon, moving-bed technology, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, condensation between hydrocarbons and non-hydrocarbons, chemical recovery, etc., can solve the problem of wide product distribution, affecting the efficiency of gas-solid separation system, running damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

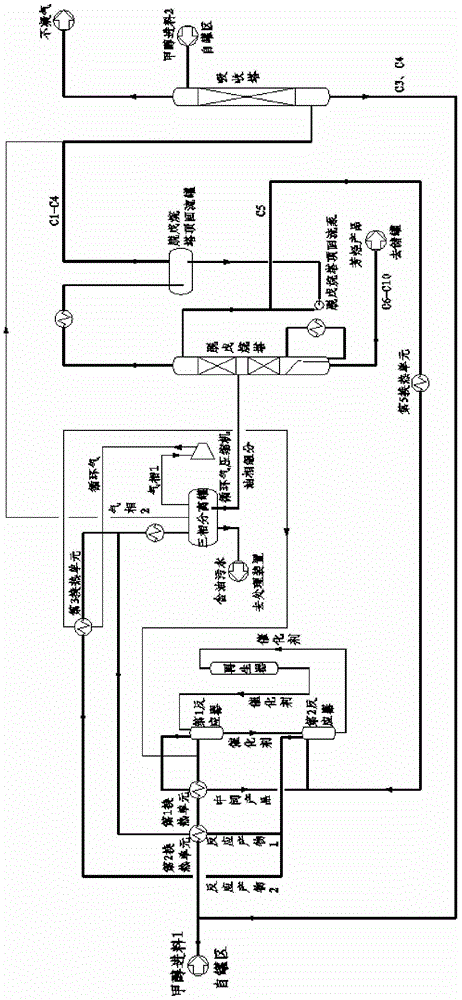

[0046] Embodiment one (see figure 1 ): Containing the first and second two reactors, the separation step adopts depentanizer fractionation.

[0047] The fresh methanol feed is pumped outside the boundary area, the pressure is increased to 0.5MPaG, and the temperature is 25°C. Fresh methanol feed 1 first enters the first reactor (equivalent to the initial reactor) after heat exchange with the reaction product, and conducts a radial moving bed contact reaction with the highly active catalyst from the regenerator. The liquid hourly space velocity is 1.0 h -1 , to generate an intermediate product (ie, the reaction product of the first reactor), with a pressure of 0.46MPaG and a temperature of 520°C. After leaving the first reactor, the intermediate product enters the first heat exchange unit, which is used as a heat source to heat the feed to the first reactor. The methanol feed 1 is heated to 480°C, and the intermediate product is cooled to 490°C. The intermediate product ente...

Embodiment 2

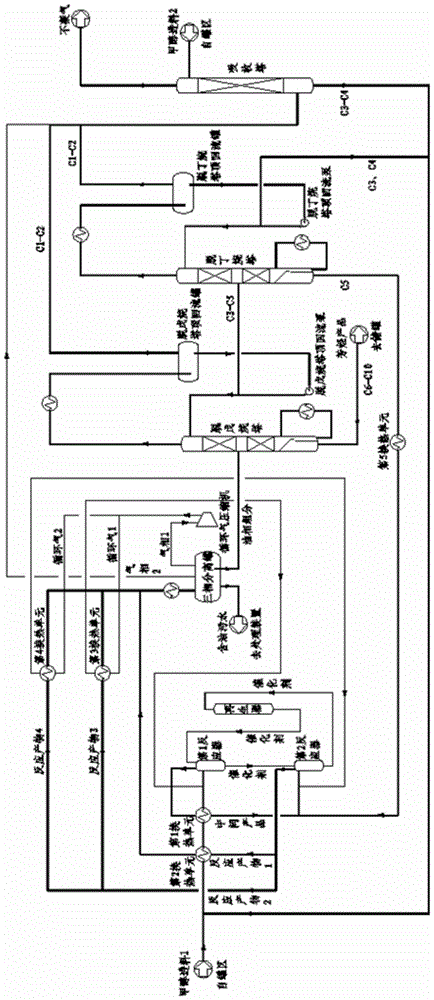

[0052] Embodiment two (see figure 2 ): Containing the first and second two reactors, the separation step adopts two-stage fractionation of a depentanizer and a debutanizer.

[0053] The fresh methanol feed is pumped through the boundary area, the pressure is increased to 1.77MPaG, and the temperature is 30°C. Fresh methanol feed 1 first enters the first reactor (equivalent to the initial reactor) after heat exchange with the reaction product, and conducts a radial moving bed contact reaction with the highly active catalyst from the regenerator. The liquid hourly space velocity is 5.0 h -1 , generate an intermediate product (ie the reaction product of the first reactor), the pressure is 1.75MPaG, and the temperature is 350°C, or 320°C. After the intermediate product leaves the first reactor, the first heat exchange unit serves as a heat source to heat the feed to the first reactor. The methanol feed is heated to 270°C or 250°C, and the intermediate product is cooled to 320°C...

Embodiment 3

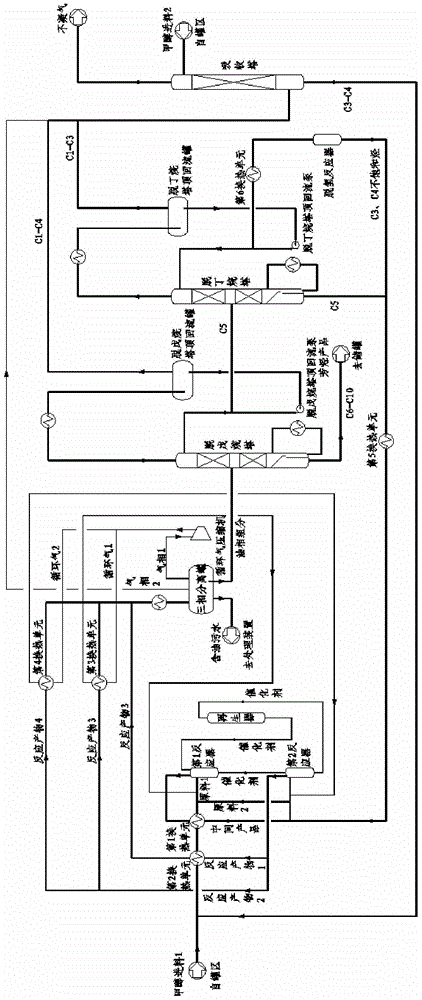

[0059] Embodiment three (see image 3 ): Including the first and second two reactors, the separation step adopts depentanizer and debutanizer two-stage fractional distillation, and uses dehydrogenation reactor to dehydrogenate C3~C4, methanol raw material is divided into two stocks and enters two a reactor.

[0060] The fresh methanol feed 1 is pumped through the boundary area, and the pressure is increased to 0.3MPaG, and the temperature is 30°C. The fresh methanol feed 1 is divided into two stocks after heat exchange with the reaction product: raw material 1 and raw material 2, which are respectively used as the first reactor (equivalent to the initial reactor), the second reactor (equivalent to the final reactor) ) feed, the flow ratio is 9:1. Raw material 1 enters the first reactor, and conducts radial moving bed contact reaction with the highly active catalyst from the regenerator, with a liquid hourly space velocity of 2.5h -1 , generate an intermediate product (ie th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com