A gas phase, liquid phase mixed hydrogenation process method

A technology of liquid phase hydrogenation and process method, which is applied in the direction of hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve problems such as the limitation of dissolved hydrogen amount, and achieve the effect of eliminating steric hindrance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

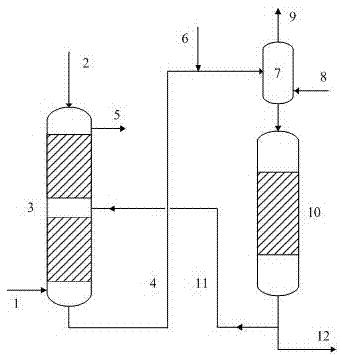

[0030] Embodiment 1~4 adopts the present invention figure 1 process shown. The composition and properties of catalysts used in the following examples are shown in Table 1. The raw materials used in the first reverse gas-phase hydrogenation reaction are the raw materials in Table 2 according to the mixed feedstock oil in the mass ratio of catalyzed wood: coke wood=50:50, and the properties of the straight-run diesel oil in the second reverse liquid-phase hydrogenation reaction are shown in Table 3, wherein the straight-run The mass ratio of diesel oil and first reaction oil is 1: 1, and the process conditions used in Examples 1-4 are listed in Table 4. The evaluation results of Examples 1-4 are shown in Table 5.

[0031] The composition and main properties of the catalyst used in the embodiment of table 1.

[0032] project anti-refining agent Second anti-refining agent Chemical composition, wt%

MoO 3 20.3 18.2 NiO 6.2 — CoO — ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com