Hydrocracking method of paraffin-based diesel oil

A hydrocracking and paraffin-based technology, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, and can solve the problems of high equipment investment and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

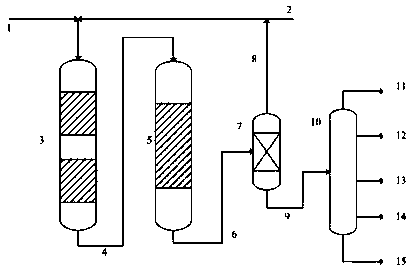

Method used

Image

Examples

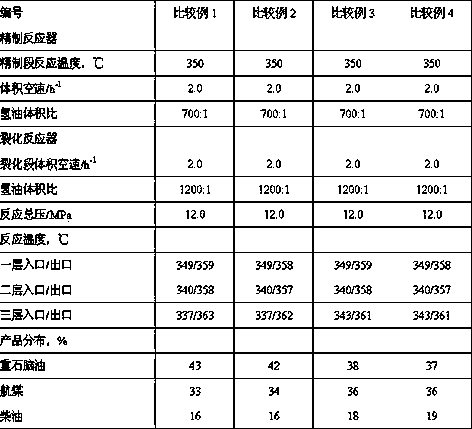

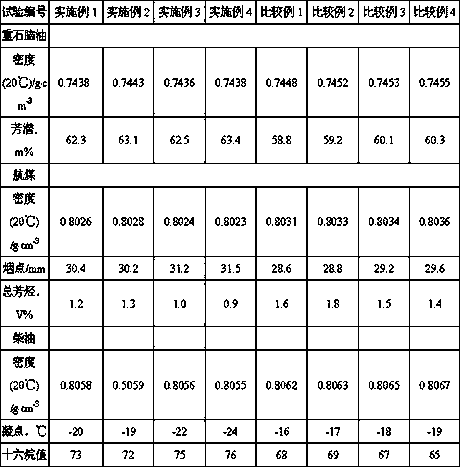

Embodiment 1

[0037] Using raw oil 1 as the raw material, the hydrorefining reactor is filled with FF-56 catalyst, and the hydrocracking reactor is equipped with 3 catalyst beds, and the catalysts are loaded sequentially along the flow direction ,catalyst and Catalyst III, the catalyst loading volume ratio is 1:1:1.

Embodiment 2

[0039] Using raw oil 1 as the raw material, the hydrorefining reactor is filled with FF-56 catalyst, and the hydrocracking reactor is equipped with 3 catalyst beds, and the catalysts are loaded sequentially along the flow direction ,catalyst and Catalyst III, the catalyst loading volume ratio is 2:1:1.

Embodiment 3

[0041] Using raw oil 1 as the raw material, the hydrorefining reactor is filled with FF-56 catalyst, and the hydrocracking reactor is equipped with 3 catalyst beds, and the catalysts are loaded sequentially along the flow direction ,catalyst and Catalyst III, the catalyst loading volume ratio is 1:2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com