Method for mixing and processing wash oil and direct coal liquefaction oil

A technology for direct liquefaction of coal and a processing method, which is applied in refining to remove heteroatoms, etc., can solve the problem of not including washing oil, and achieve the effects of avoiding excessive temperature rise, promoting coal conversion, and improving economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

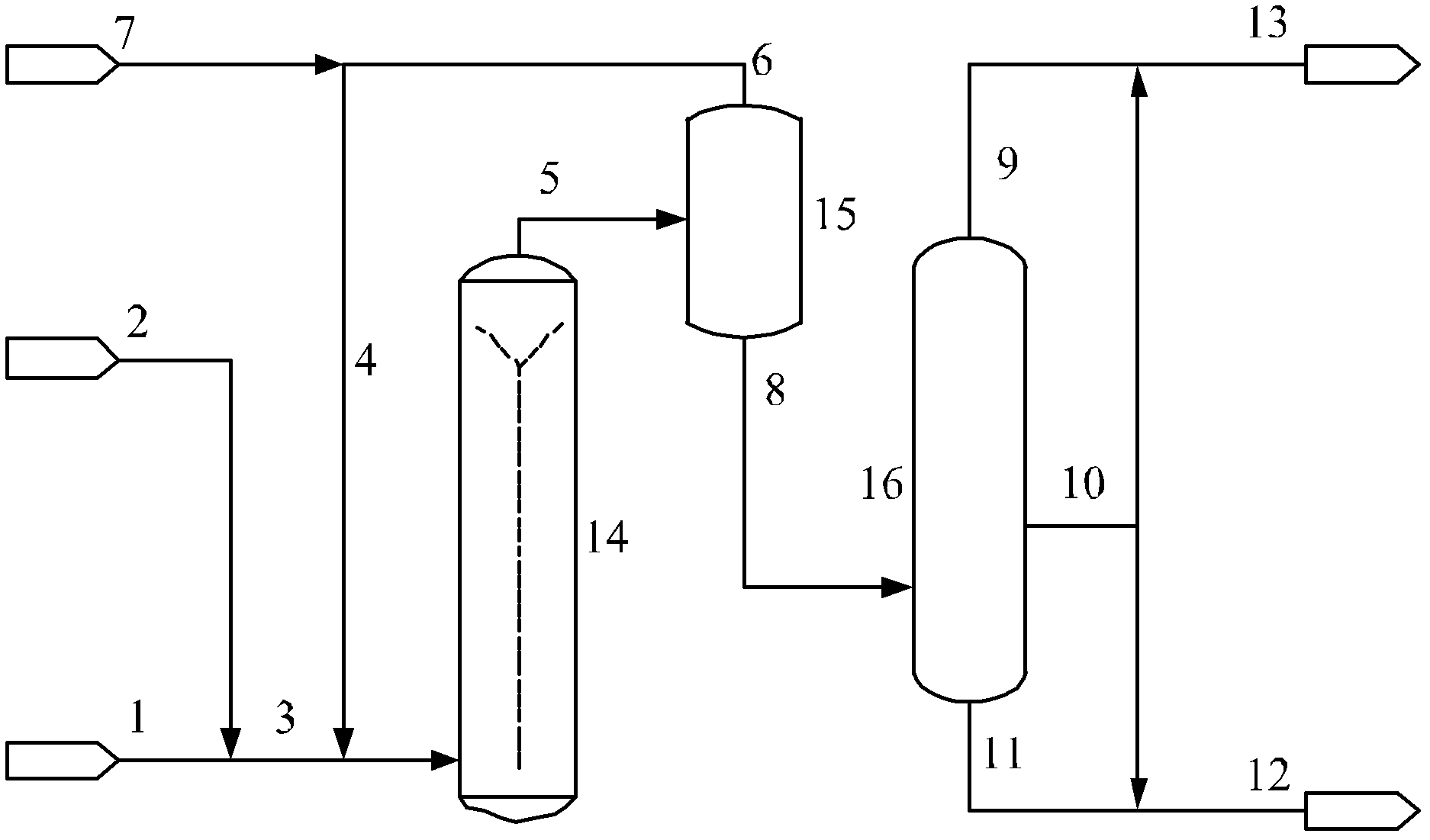

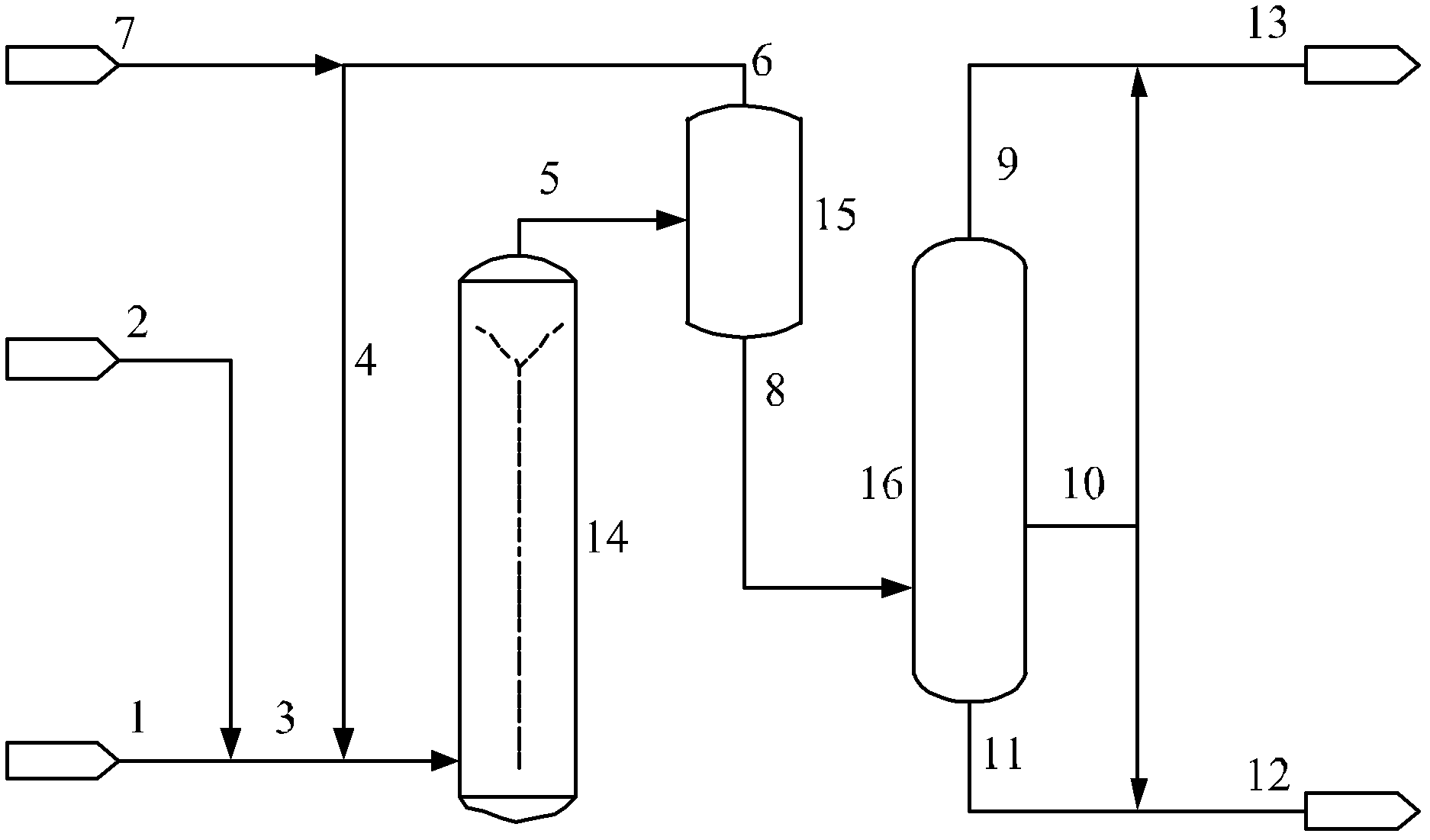

Method used

Image

Examples

Embodiment 1

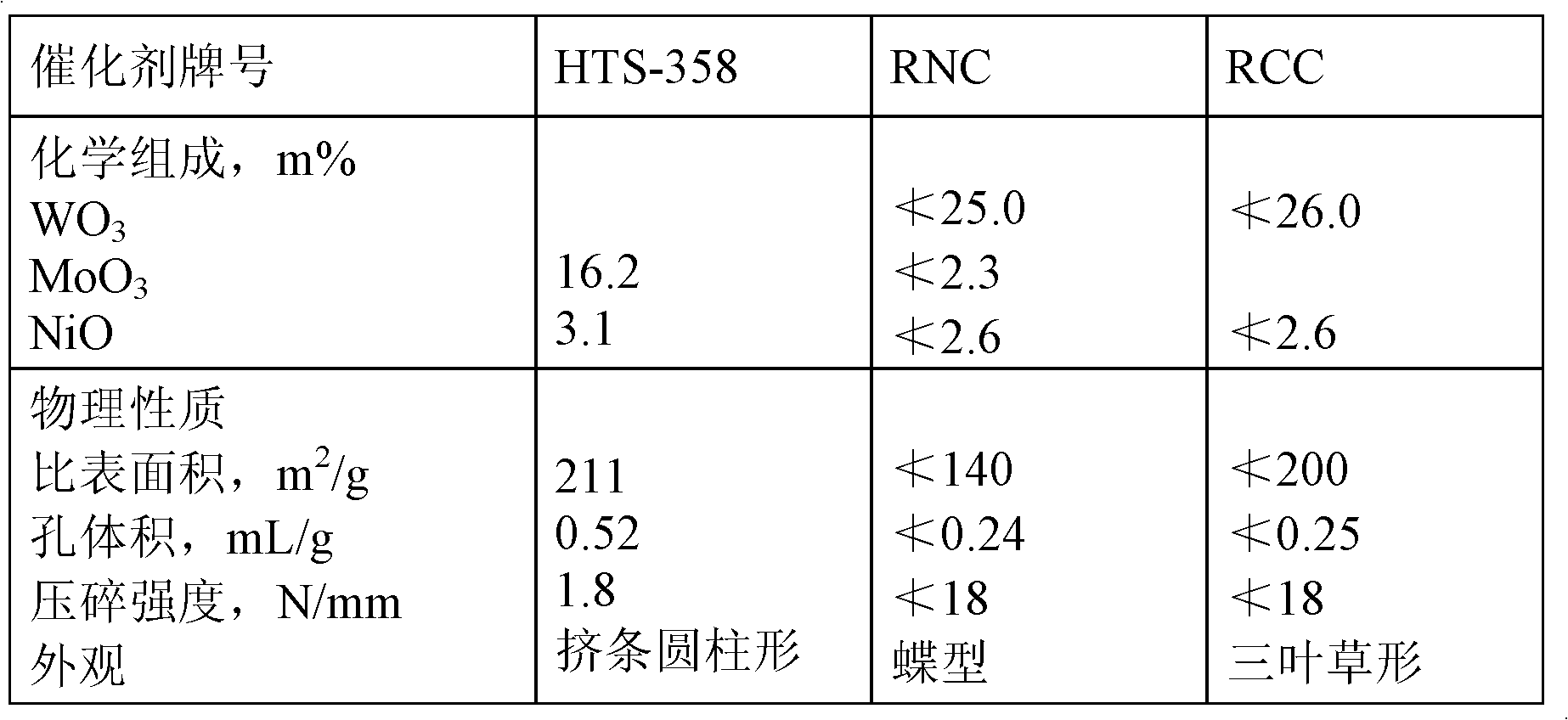

[0060] The coal direct liquefaction oil and washing oil shown in Table 1 were mixed at a mass ratio of 90:10. The properties of the mixed raw material oil after mixing are shown in Table 1, and the group composition analysis data of the washing oil are shown in Table 2.

[0061] The test process is as follows:

[0062] Hydrogenation test is carried out on the mixed raw oil, and the obtained whole distillate oil is distilled and cut into three fractions, namely, light distillate oil less than 220°C, heavy distillate oil greater than 350°C and middle distillate oil at 220°C-350°C Oil. The hydrogen donating solvent is obtained by mixing 3 / 4 weight of middle distillate oil with heavy distillate oil above 350°C. Mix the remaining 1 / 4 of the middle distillate oil with the light distillate oil below 220°C to obtain the crude oil of the liquefied product, and carry out the hydrogenation upgrading test on the crude oil of the liquefaction product according to the conventional method. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com