Direct coal liquefaction method

A technology of direct coal liquefaction and coal powder, applied in the field of coal chemical industry, can solve the problems of poor hydrogen supply performance of hydrogen supply solvent, high hydrogen consumption of direct coal liquefaction, low oil yield, etc., achieve strong hydrogen supply capacity and improve coal liquefaction Conversion rate, oil yield, hydrogen consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

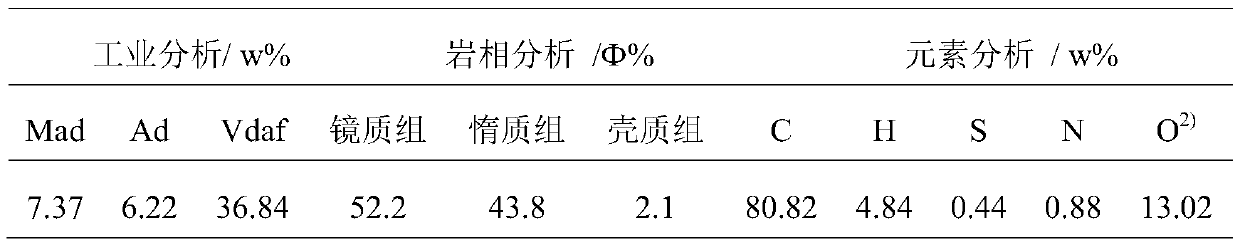

[0043] First, tetrahydronaphthalene, dihydrophenanthrene, dihydroanthracene, naphthalene, and decahydronaphthalene are mixed according to a mass ratio of 1:1:1:1:1 as a hydrogen-donating solvent; the dried water content is 0.5-4.0wt %, coal powder with a particle size of ≤0.15mm and a hydrogen-donating solvent are loaded into the autoclave at a mass ratio of 45:55, the initial hydrogen pressure is set to 10Mpa, and the catalyst is Fe 2 o 3 , Fe addition amount is 3.0% of dry coal mass fraction, cocatalyst is sulfur, n(S) / n(Fe)=2.0. After the oil-coal slurry is heated to a reaction temperature of 455°C, the temperature is kept constant for 60 minutes. After the reaction is completed, the temperature of the kettle is lowered to 200°C within 20 minutes.

[0044] Finally, after Soxhlet extraction of the reaction solution obtained above, the n-hexane soluble matter is collected as liquefied oil, and the n-hexane insoluble part is extracted with tetrahydrofuran. Finally, the conversi...

Embodiment 2

[0046] First, tetrahydronaphthalene, dihydrophenanthrene, dihydroanthracene, naphthalene, and decahydronaphthalene are mixed according to a mass ratio of 6:1:1:1:1 as a hydrogen-donating solvent; the dried water content is 0.5-4.0wt %, coal powder with a particle size of ≤0.15mm and a hydrogen-donating solvent are loaded into the autoclave at a mass ratio of 45:55, the initial hydrogen pressure is set to 10Mpa, and the catalyst is Fe 2 o 3 , Fe addition amount is 3.0% of dry coal mass fraction, cocatalyst is sulfur, n(S) / n(Fe)=2.0. After the oil-coal slurry is heated to a reaction temperature of 455°C, the temperature is kept constant for 60 minutes. After the reaction is completed, the temperature of the kettle is lowered to 200°C within 20 minutes.

[0047] Finally, after Soxhlet extraction of the reaction solution obtained above, the n-hexane soluble matter is collected as liquefied oil, and the n-hexane insoluble part is extracted with tetrahydrofuran. Finally, the conver...

Embodiment 3

[0049] First, tetrahydronaphthalene, dihydrophenanthrene, dihydroanthracene, naphthalene, and decahydronaphthalene are mixed according to a mass ratio of 1:6:1:1:1 as a hydrogen-donating solvent; the dried water content of 0.5-4.0wt %, coal powder with a particle size of ≤0.15mm and a hydrogen-donating solvent are loaded into the autoclave at a mass ratio of 45:55, the initial hydrogen pressure is set to 10Mpa, and the catalyst is Fe 2 o 3 , Fe addition amount is 3.0% of dry coal mass fraction, cocatalyst is sulfur, n(S) / n(Fe)=2.0. After the oil-coal slurry is heated to a reaction temperature of 455°C, the temperature is kept constant for 60 minutes. After the reaction is completed, the temperature of the kettle is lowered to 200°C within 20 minutes.

[0050] Finally, after Soxhlet extraction of the reaction solution obtained above, the n-hexane soluble matter is collected as liquefied oil, and the n-hexane insoluble part is extracted with tetrahydrofuran. Finally, the conver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com