Production device and preparation method of hydrogen-donor solvent

A hydrogen supply solvent and hydrogen supply technology, applied in the field of coal chemical industry, can solve the problems of affecting coal conversion rate and oil yield, poor hydrogen supply capacity, weak hydrogen supply capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

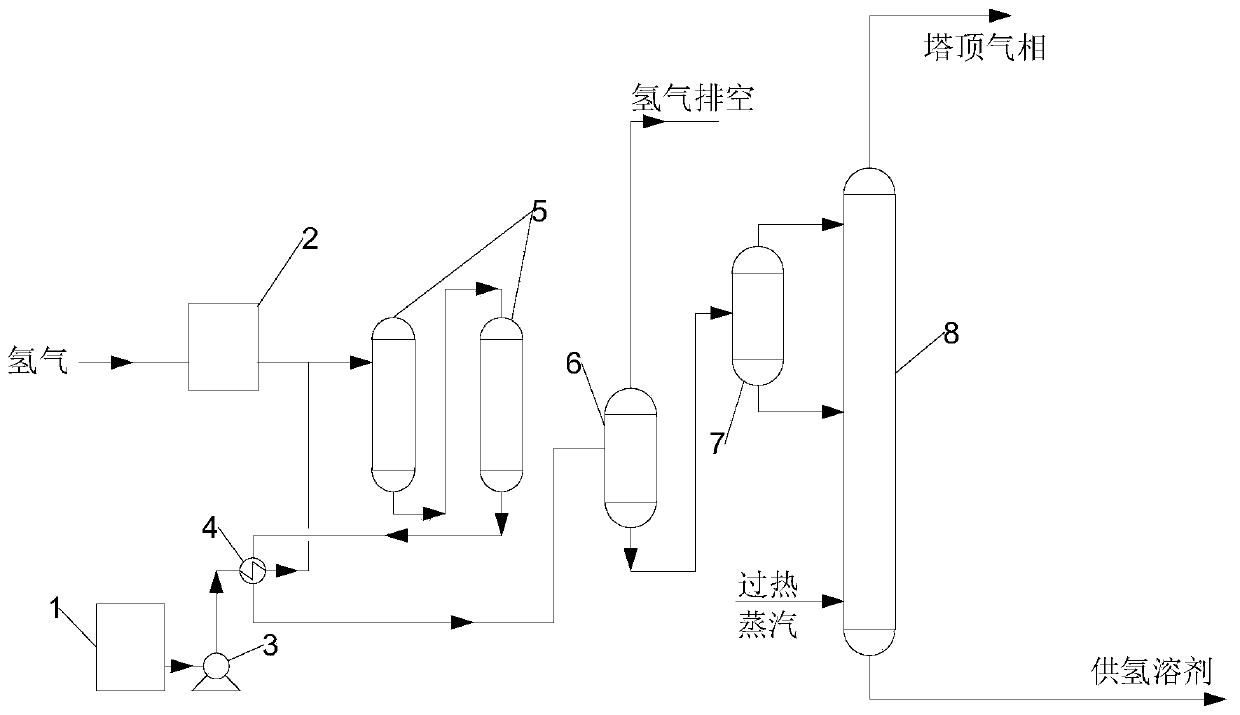

[0061] This embodiment provides a device for producing a hydrogen-donating solvent, and the schematic diagram of the device is as follows figure 1 As shown, it includes a hydrogen supply unit, a raw oil supply unit, a hydrogenation reaction unit, a separation unit and a stripper 8 .

[0062] The raw oil supply unit includes a raw oil storage tank 1, a raw oil delivery pump 3, and a heat exchanger 4 connected in sequence;

[0063] The hydrogen supply unit includes a hydrogen heating furnace 2, the outlet of the hydrogen heating furnace 2 is connected to the inlet of the hydrogenation reaction unit, and the connecting pipeline between the hydrogen heating furnace 2 and the inlet of the hydrogenation reaction unit is also connected to the heat exchange unit. The outlet of device 4 is connected;

[0064] The separation unit includes a hot high-pressure separator 6 and a hot low-pressure separator 7. The hot high-pressure separator 6 is provided with a top gas outlet and a first b...

Embodiment 2

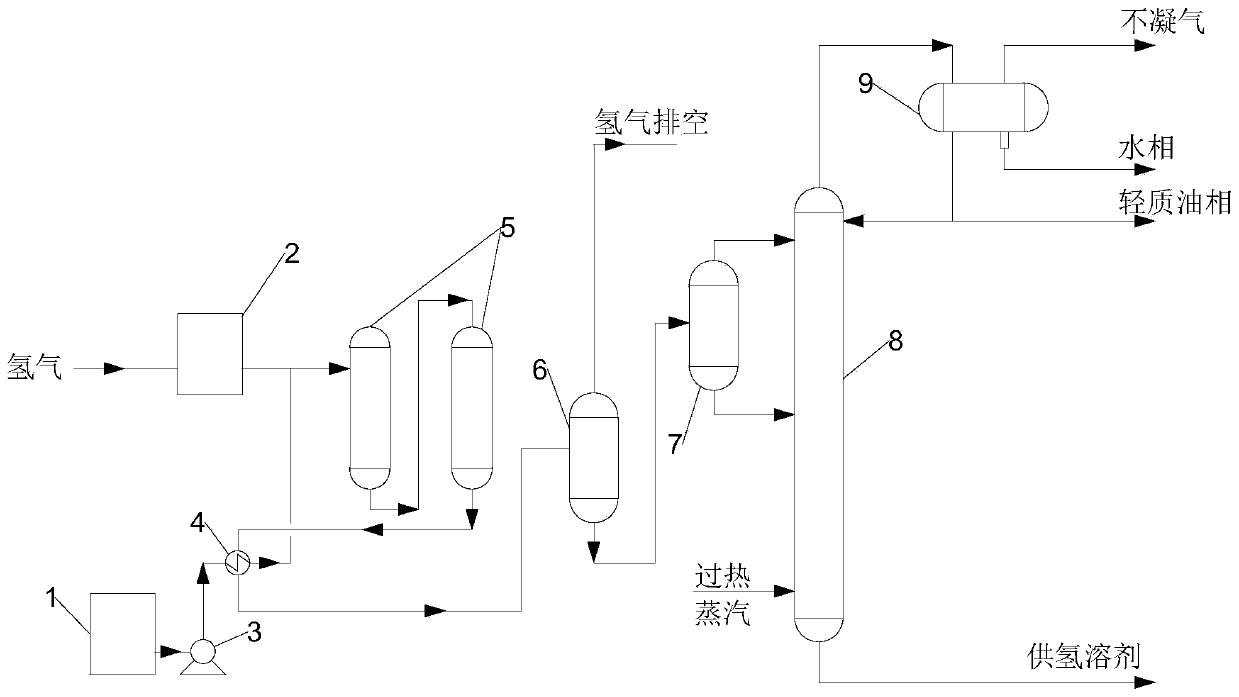

[0068] This embodiment provides a device for producing a hydrogen-donating solvent, and the schematic diagram of the device is as follows figure 2 As shown, except that the top of the stripper 8 is also provided with a stripper reflux tank 9, all the others are the same as in Embodiment 1.

[0069] The raw oil in the raw oil storage tank 1 flows through the heat exchanger 4 under the action of the raw oil delivery pump 3, and after being heated, it mixes with the hydrogen gas flowing out of the hydrogen heating furnace 2, and enters the fixed bed reactor 5 together for reaction. After the end, the high-temperature mixture flows through the heat exchanger 4 to heat the raw material oil, and the cooled high-temperature mixture is separated into gas and liquid in the hot high-pressure separator 6, the gas is discharged from the top gas outlet, and the hydrogenated bottom oil is discharged from the first bottom The port flows into the hot low-pressure separator 7, and is fraction...

Embodiment 3

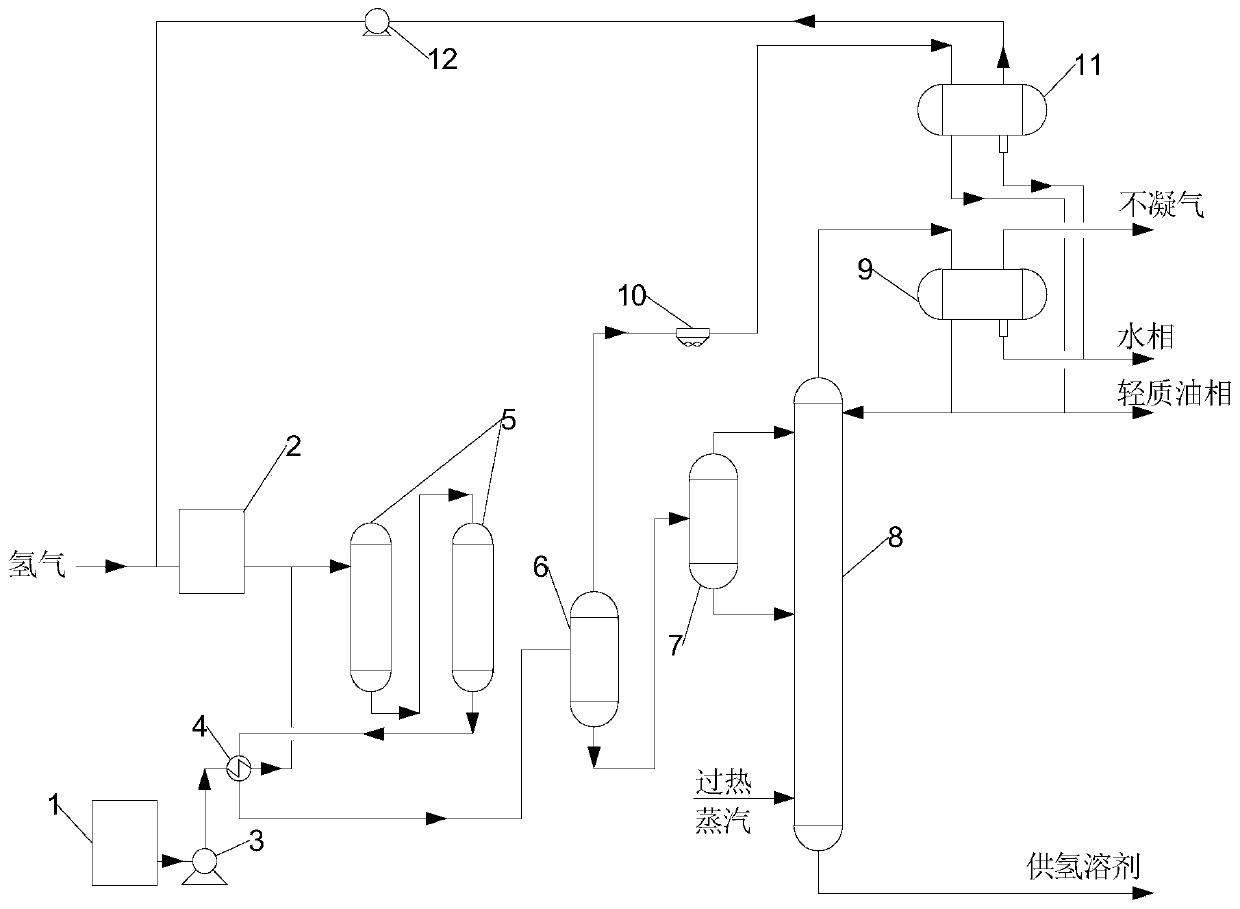

[0072] This embodiment provides a device for producing a hydrogen-donating solvent, and the schematic diagram of the device is as follows image 3 As shown, compared with Example 2, the device provided in Example 3 is also provided with a hydrogen recovery unit, which includes an air cooler 10, a gas-liquid separator 11 and a compressor 12 connected in sequence, and the air cooling The inlet of the device 10 is connected to the top gas outlet of the hot high-pressure separator 6, the gas outlet of the compressor 12 is connected to the inlet of the hydrogen heating furnace 2, and the water phase outlet of the gas-liquid separator 11 is connected to the gas outlet of the gas-liquid separator 11. The water phase outlet of the stripper reflux tank 9 is connected, and the light oil phase outlet is connected with the light oil phase outlet of the stripper reflux tank 9 .

[0073] The raw oil in the raw oil storage tank 1 flows through the heat exchanger 4 under the action of the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com