Recycling solvent and preparation method thereof

A technology for recycling solvent and solvent, applied in the field of coal chemical industry, can solve the problems of insufficient hydrogen supply capacity, high hydrogen consumption, harsh process conditions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the preparation method provided by the present invention, those skilled in the art can select specific process conditions in the first hydrogenation process. In a preferred embodiment, the first hydrogenation process includes the step of carrying out the first hydrogenation reaction of medium-temperature oil and hydrogen under the action of the first catalyst; wherein, the temperature of the first hydrogenation reaction is 300-380°C , preferably 320-360° C.; the reaction pressure of the first hydrogenation reaction is 10-21 MPa, preferably 16-20 MPa. Limiting the temperature and pressure of the first hydrogenation process within the above range is beneficial to improve the hydrogenation effect of medium temperature oil.

[0033] In a preferred embodiment, the volume ratio of hydrogen to medium temperature oil in the first hydrogenation reaction process is 100-1500, preferably 500-1000; the reaction volume space velocity is 0.5-4.5h -1 , preferably 0.8-2.5h -1 . Li...

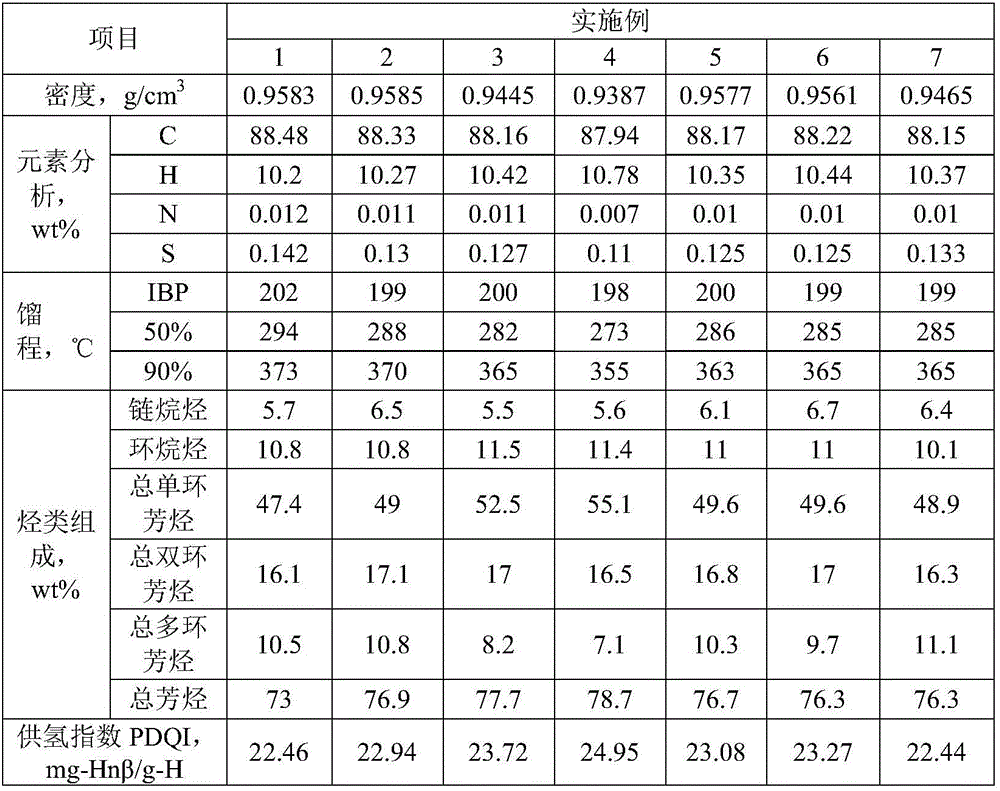

Embodiment 1

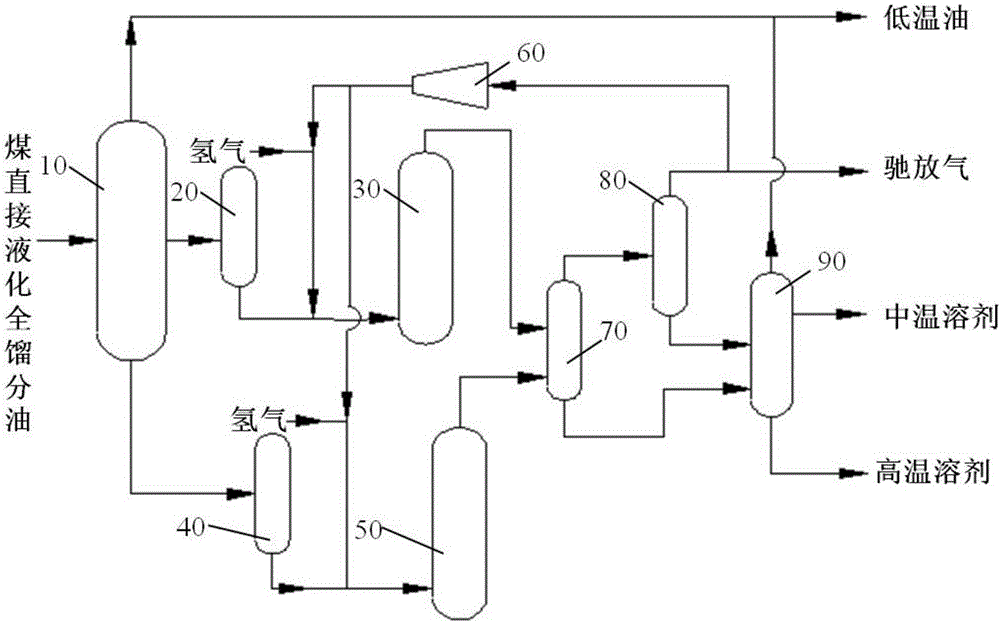

[0044] Such as figure 1 As shown, the direct liquefied coal fraction oil is subjected to the first fractionation process in the first fractionation tower 10 at a pressure of 0.05 MPa to obtain low-temperature oil, medium-temperature oil and high-temperature oil, wherein the low-temperature oil is a distillate oil less than 200°C. Medium-temperature oil is distillate oil at 200-300°C, and high-temperature oil is distillate oil above 300°C.

[0045] Above-mentioned middle temperature oil enters in the first hydrogenation reactor 30 (fixed-bed reactor) after the first surge tank 20 is stabilized in Ni-Mo / Al 2 o 3 (Ni-M O is the active component, Al 2 o 3 is the carrier) to carry out the first hydrogenation reaction to obtain the first hydrogenation stable oil, wherein the pressure of the first hydrogenation process is 16MPa, the temperature is 320°C, the hydrogen-oil ratio is 800v / v, and the reaction space velocity is 1.5h -1 .

[0046] The above-mentioned high-temperature...

Embodiment 2

[0052] The pressure of the first hydrogenation reaction and the second hydrogenation reaction is 20MPa, and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com