Preparation method of high-matching coal-oil slurry

A preparation method, oil-coal slurry technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve problems such as coking, coal and heavy oil synergistic effects, etc., to slow down wear, reduce non-production load, and improve oil yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

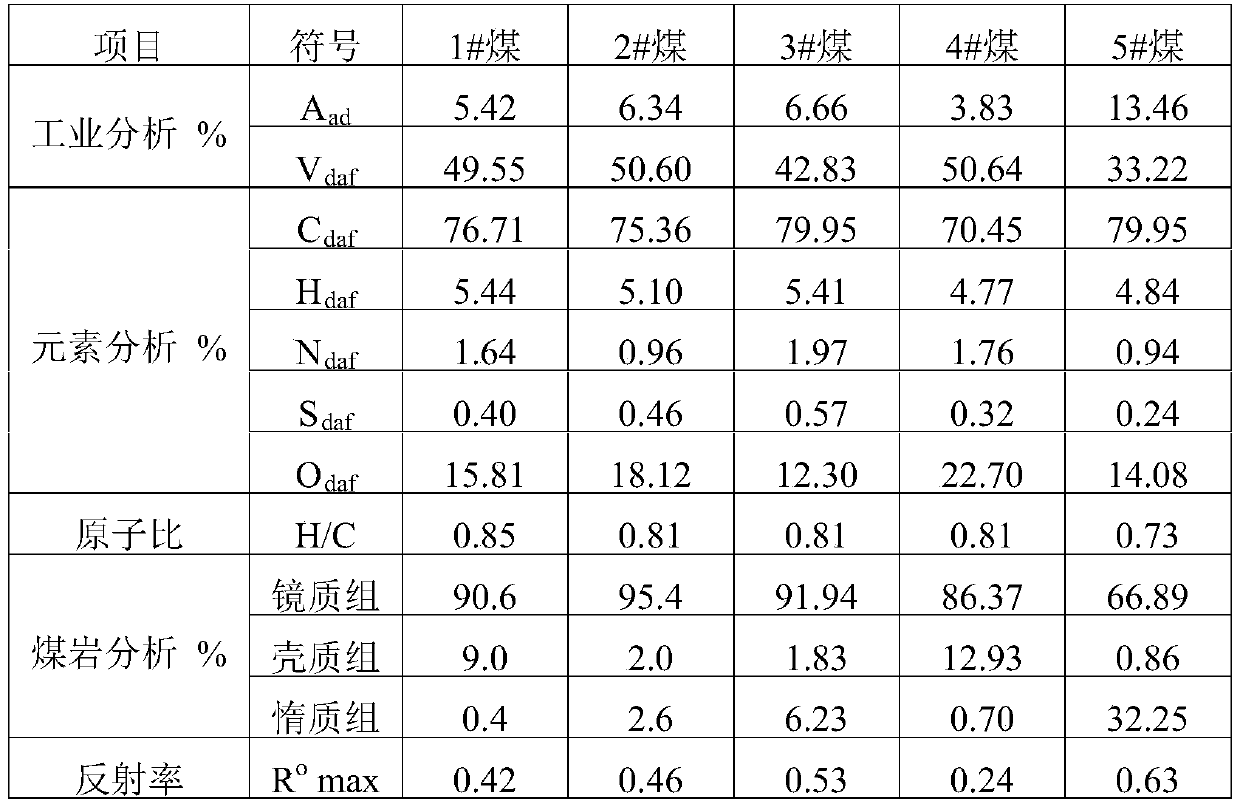

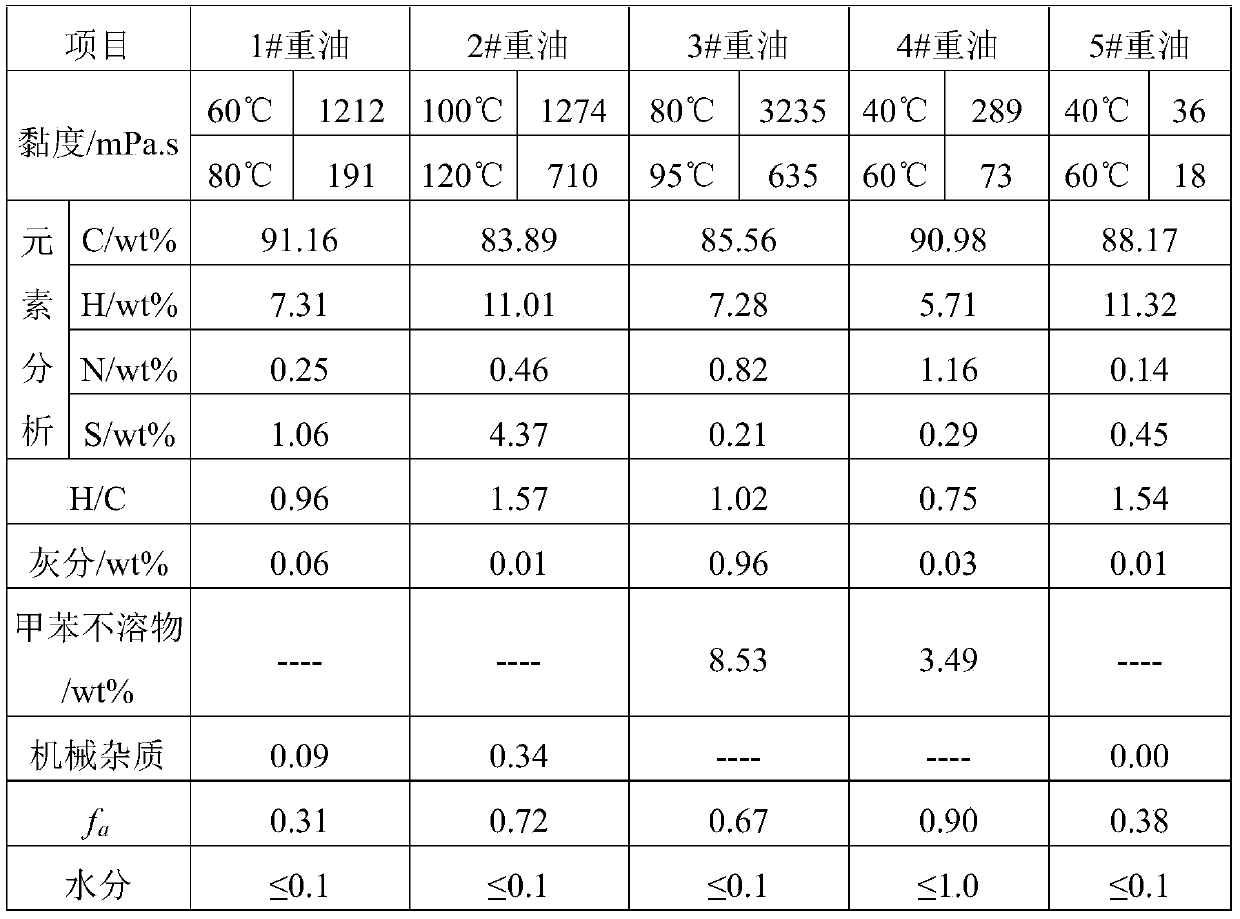

Method used

Image

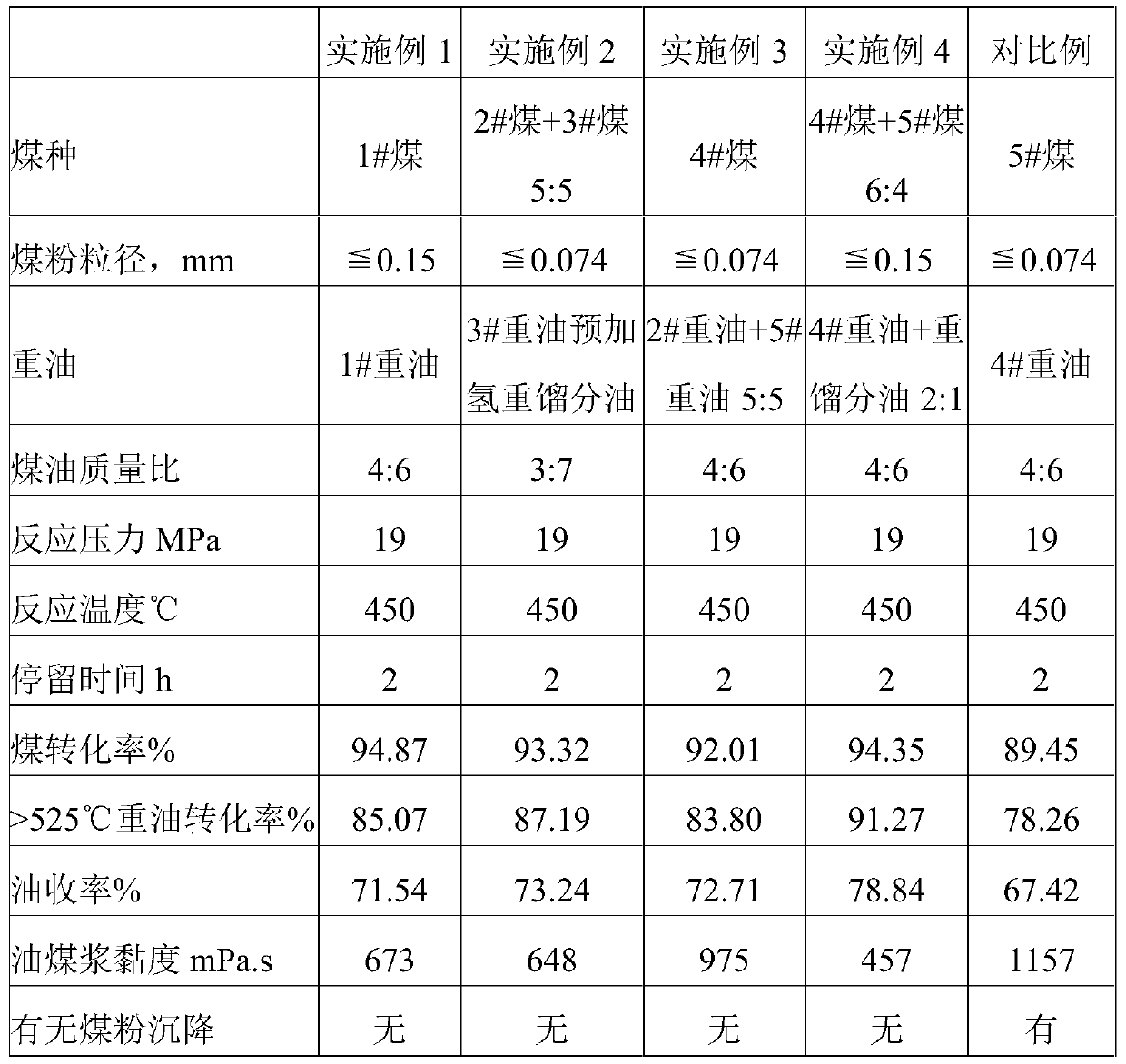

Examples

Embodiment 1

[0076] Dry the washed 1# coal to a moisture content of 3.0%, then crush and grind it into coal powder below 0.074mm, mix the coal powder and 1# heavy oil at a mass ratio of 4:6, and add 1% (with coal and The total amount of heavy oil was used as the basis) Fe catalyst was stirred under a 120r / min stirring paddle for 45min, and part of the oil-coal slurry was taken out and left to stand at 90°C for 30min, and no coal dust particle sedimentation was found.

[0077] The oil-coal slurry prepared by the above method has a viscosity of 673mPa·s (90°C). The oil-coal slurry is subjected to hydrogenation reaction. The properties of the oil-coal slurry and the results of the hydrogenation reaction in this embodiment are shown in Table 3.

Embodiment 2

[0079] The washed 2# coal and 3# coal are mixed according to the mass ratio of 5:5 and dried until the water content is 2.1%, and then crushed and ground into coal powder below 0.15mm.

[0080] The 3# heavy oil is pre-hydrogenated at a hydrogen partial pressure of 17 MPa and a temperature of 430°C, and the pre-hydrogenated 3# heavy oil is distilled to obtain a heavy distillate oil greater than 350°C.

[0081] Then the coal powder and 3# heavy oil pre-hydrogenated heavy distillate oil greater than 350°C were mixed in a ratio of 3:7, and 1% (based on the total amount of coal and heavy oil) Fe catalyst was added. Stir for 60 minutes at the same time, accompanied by the circulating flow of the pump, take out part of the oil-coal slurry and let it stand for 30 minutes at 90°C, no coal dust particles are found to settle.

[0082] The oil-coal slurry prepared by the above method has a viscosity of 648 mPa·s (90° C.), and the oil-coal slurry is subjected to hydrogenation reaction. The...

Embodiment 3

[0084] Dry the washed 4# coal until the water content is 3.5%, crush it and grind it into coal powder below 0.15mm, mix the coal powder with 2# heavy oil and 5# heavy oil in a ratio of 4:3:3, add 200mg / kg of Mo catalyst was stirred for 120min under a stirring paddle of 70r / min, accompanied by the circulating flow of the pump, and part of the oil-coal slurry was taken out and left to stand at 90°C for 30min, and no settling of pulverized coal particles was found.

[0085] The oil-coal slurry prepared by the above method has a viscosity of 975 mPa·s (90° C.), and the oil-coal slurry is subjected to hydrogenation reaction. The properties of the oil-coal slurry and the results of the hydrogenation reaction in this embodiment are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com