Functional copolymer directly prepared from higher olefin mixture and preparation method

A technology of hydrocarbon mixtures and copolymers, which is applied in the field of functional copolymers directly prepared from high-carbon hydrocarbon mixtures and its preparation, which can solve the problems of low penetration rate of C9 petroleum resin production, limited reuse of C9 distillate resources, and complicated processes and other problems, to achieve the effect of easy recycling and reuse, low toxicity and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

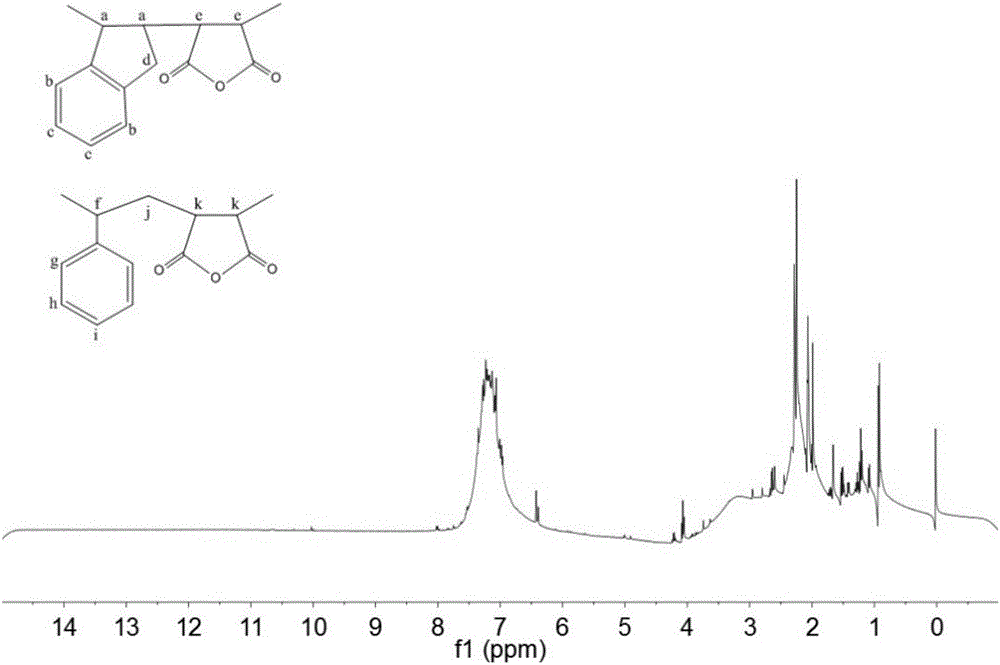

Embodiment 1

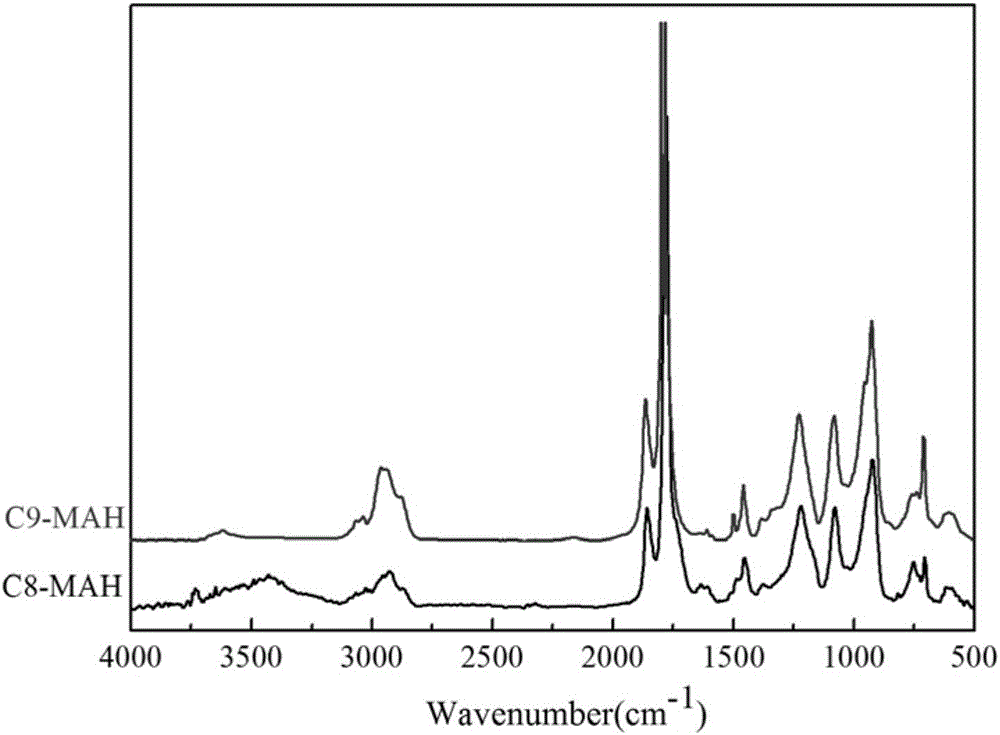

[0033] Using xylene as the solvent of the reaction system, 0.8g of maleic anhydride and 0.084g of azobisisobutyronitrile were dissolved in 2.0g of C8 fraction (see Table 1 for composition, olefin content 27.64%) and 6mL of xylene, and ultrasonically After fully dissolving and mixing uniformly, the mass ratio of MAH to C8 fraction in the reaction system is 0.40; the system is ventilated with nitrogen for 20 minutes, the reaction temperature is 70°C, and the reaction time is 6 hours. After the reaction was completed, the reaction product was centrifuged at 4000 rpm for 10 minutes, washed with petroleum ether, centrifuged three times, and vacuum-dried to constant weight to obtain 1.27 g of C8-MAH copolymer with a yield of 94.23%. .

[0034] The copolymer was analyzed for three elements of C, H and O, and the results are shown in Table 5. It can be seen that the content of C element in the obtained C8-MAH copolymer is about 72.06%, the content of H element is about 5.42%, and the...

Embodiment 2

[0036] Using the mixed solvent of isoamyl acetate and n-heptane as the solvent of the reaction system, 1.0 g of maleic anhydride and 0.090 g of azobisisobutyronitrile were dissolved in 4.0 g of C8 fraction (see Table 1 for composition, olefin content 27.64%) and 4 mL of acetic acid In isoamyl ester and 2 mL of n-heptane, after ultrasonically dissolving and mixing uniformly, the mass ratio of MAH to C8 fraction in the reaction system is 0.40; the system is blown with nitrogen for 20 minutes, the reaction temperature is 75°C, and the reaction time is 6 hours. After the reaction was completed, the reaction product was centrifuged at 4000 rpm for 10 minutes, washed with petroleum ether, and centrifuged three times. Vacuum drying to constant weight yielded 1.91 g of C8-MAH copolymer with a yield of 90.55%.

Embodiment 3

[0038] With isoamyl acetate as the solvent of the reaction system, 0.4 g of maleimide and 0.072 g of dicumyl peroxide were dissolved in 2.0 g of C8 fraction (see Table 1 for composition, olefin content 27.64%) and 2 mL of acetic acid In the isoamyl ester, ultrasonically dissolve and mix evenly, the mass ratio of maleimide to C8 fraction in the reaction system is 0.20; the system is blown with nitrogen for 20 minutes, the reaction temperature is 120°C, and the reaction time is 6 hours. After the reaction was completed, the reaction product was centrifuged at 4000 rpm for 10 minutes, washed with petroleum ether, and centrifuged three times. Vacuum drying to constant weight yielded 0.86 g of C8-maleimide copolymer with a yield of 90.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com