System and process for preparing olefin by taking coal and coke-oven gas as raw materials

A technology of coke oven gas and raw materials, which is applied in the field of olefin production system, can solve problems such as waste of resources, and achieve the effects of simplified process, optimized resource allocation, and high operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

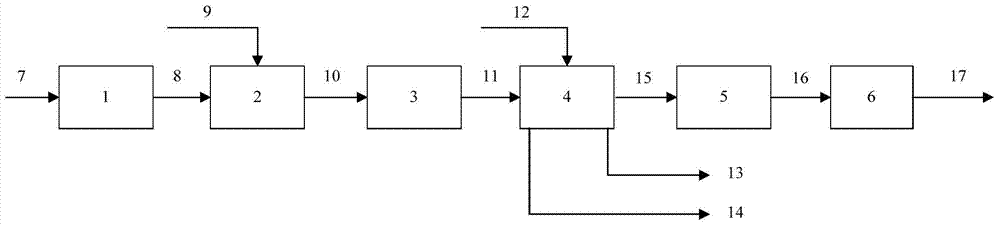

[0037] A system for producing olefins from coal and coke oven gas, comprising a coal water slurry preparation unit 1, a coal gasification unit 2, a synthesis gas purification unit 4, a methanol synthesis unit 5 and an olefin synthesis unit 6 connected in sequence, the water The coal slurry preparation unit 1 is provided with a raw material inlet that can be fed into pulverized coal. The coal water slurry outlet of the coal water slurry preparation unit 1 is directly connected with the coal water slurry raw material inlet of the coal gasification unit 2. The coal gasification of the coal gasification unit 2 is roughly synthesized The gas outlet is directly connected to the crude synthesis gas inlet of the synthesis gas purification unit 4 through a pipeline, the synthesis gas purification unit 4 is provided with a net synthesis gas outlet, the methanol synthesis unit 5 is provided with a synthesis gas inlet for methanol synthesis and a methanol outlet, and the methanol outlet is ...

Embodiment 2

[0059] Utilize the system described in embodiment 1 to carry out olefin preparation, concrete implementation is as follows:

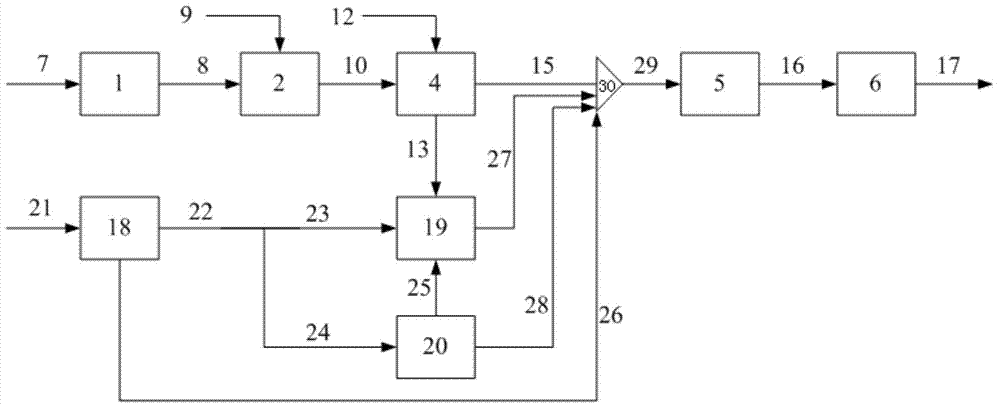

[0060] The raw coal pulverized flow that enters the system of the present invention is 125.85t / h. The raw coke oven gas flow rate is 201.4t / h, and the feed ratio of coke oven gas to pulverized coal is 1.6. The composition of coke oven gas is shown in Table 1. The general flow chart of coal and coke oven gas combined production of olefins can be found in figure 2 .

[0061] Table 1 Composition of coke oven gas

[0062] Element

H 2

CH 4

CO

CO 2

N 2

O 2

C m h n

59.5

24.8

6.5

5.5

3.2

0.3

0.2

[0063] Coke oven gas separation process:

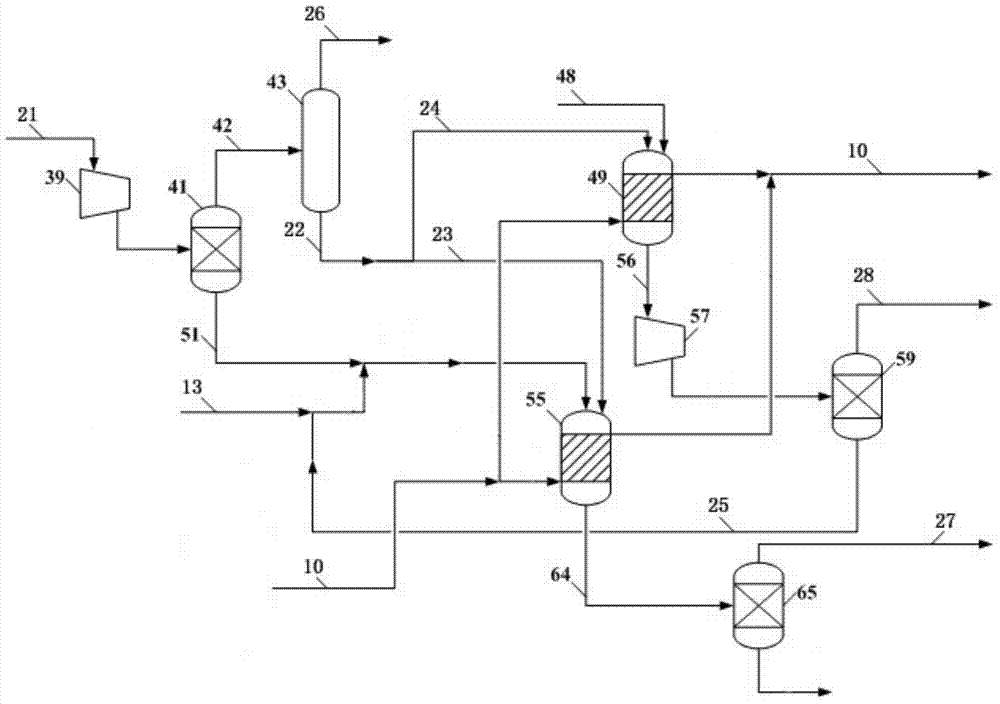

[0064] See the detailed process image 3 , the raw material coke oven gas 21 entering the process is subjected to a three-stage compression heat exchange process through the first compression heat exchanger 39, and...

Embodiment 3

[0072] Utilize the system described in embodiment 1 to carry out olefin preparation, concrete implementation is as follows:

[0073] The flow rate of raw coal powder entering the system of the present invention is 109.75t / h, the flow rate of raw coke oven gas is 142.67t / h, and the feed ratio of coke oven gas and coal powder is 1.3. The composition of coke oven gas is shown in Table 1. The general flow chart of coal and coke oven gas combined supply to olefins process is shown in the appendix figure 2 .

[0074] Table 1 Composition of coke oven gas

[0075] Element

H 2

CH 4

CO

CO 2

N 2

O 2

C m h n

61.7

21.8

4.1

6.4

3.2

0.3

2.5

[0076] Coke oven gas separation process:

[0077] See the detailed process image 3 , the raw material coke oven gas 21 entering the process is subjected to a three-stage compression heat exchange process through the first compression heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com