Process and plant for the recovery and utilization of higher olefins in the olefin synthesis from oxygenates

一种化合物、芳香族化合物的技术,应用在从含氧有机化合物制烃、含羟基化合物脱水制备醚、化学仪器和方法等方向,能够解决丙烯得率降低、消耗等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

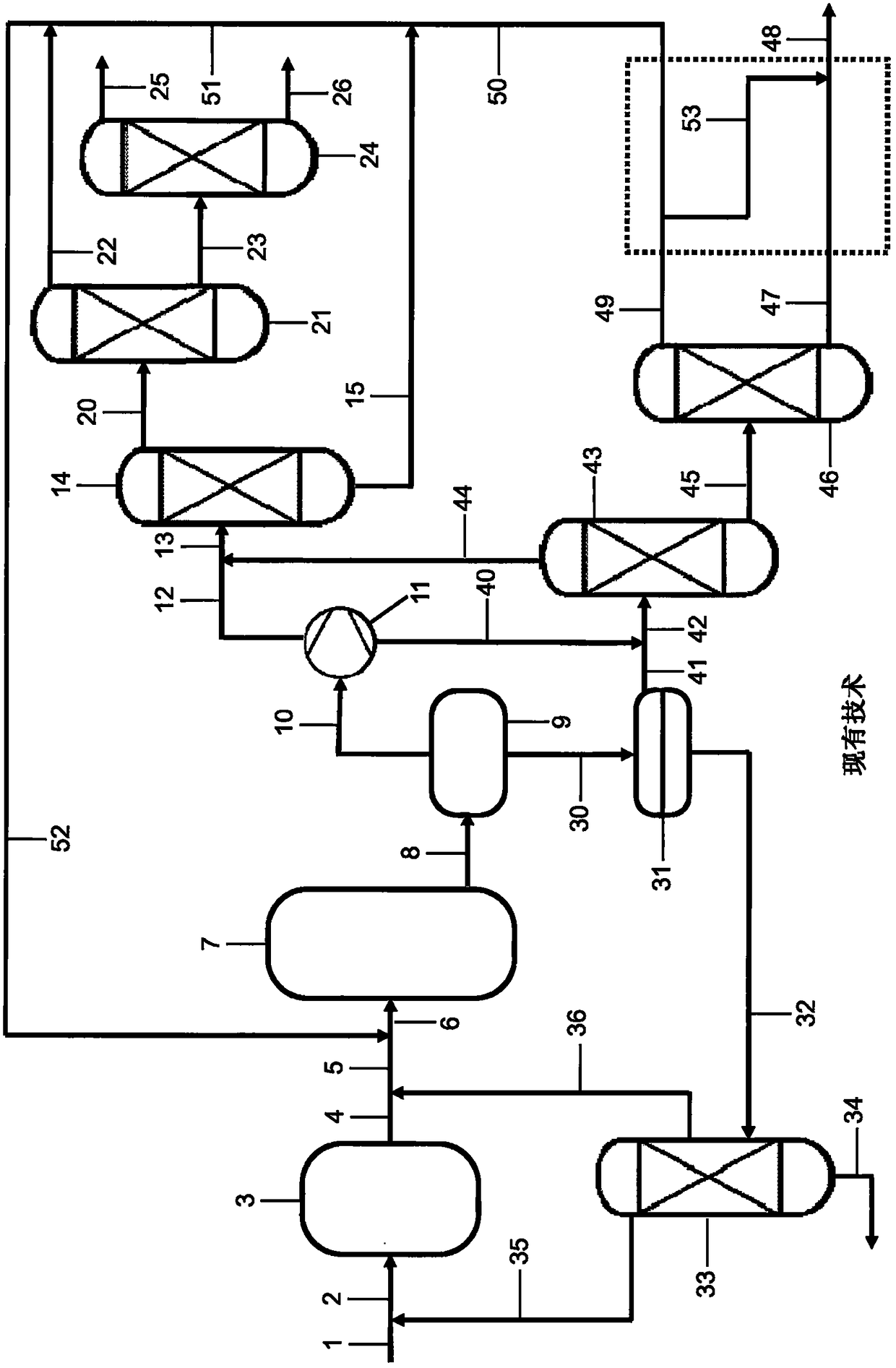

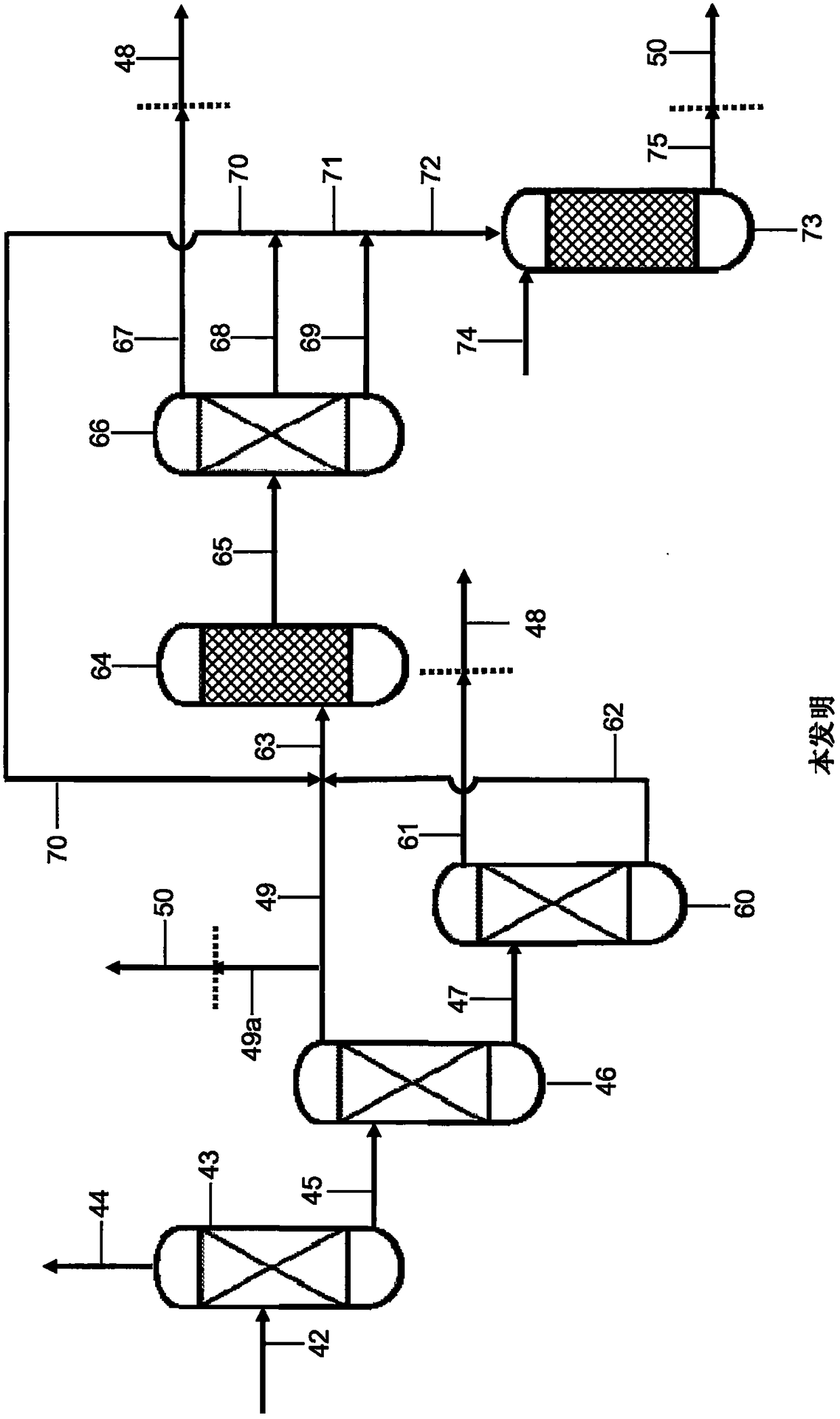

[0043] Thermal separation processes in the sense of the present invention include all separation processes based on the attainment of a thermodynamic phase equilibrium. Distillation or rectification is preferred. In principle, however, it is also conceivable to use other thermal separation processes, such as extraction or extractive distillation.

[0044] Fluid communication between two regions or sections of equipment is understood to be any kind of communication enabling a fluid such as a reaction product or a hydrocarbon fraction to flow from one of the two regions to the other, whether or not there are any intervening regions, Components or necessary means of delivery.

[0045] In principle, oxygenates are understood to be all oxygen-containing hydrocarbon compounds which can be converted under oxygenate conversion conditions into olefins, especially short-chain olefins such as propylene and other hydrocarbon products.

[0046] Short-chain olefins according to the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com