A kind of preparation method of supported iron-based catalyst

A catalyst and carrier technology, which is applied in the field of preparation of supported iron-based catalysts, can solve the problems of low-carbon olefin catalyst activity and stability, high catalyst cost, and low CO conversion rate, etc., to achieve outstanding comprehensive performance and improve conversion rate, the effect of increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

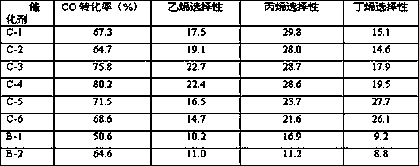

Examples

example 1

[0025] Weigh commercially available alumina (pore volume is 0.96ml / g, specific surface area is 286.81m 2 / g, saturated water absorption is 145ml / g, provided by Fushun Branch of Sinopec Catalyst Co., Ltd., the following examples and comparative examples all use the alumina), the mass concentration is 5% ammonium carbonate aqueous solution saturated spray dipping oxidation Aluminum, immediately after drying at 95°C for 1 hour, the adsorption capacity of the ammonium carbonate aqueous solution is 60% of the saturated absorption solution of the alumina carrier, aging at 60°C for 7 hours, drying at 100°C for 24 hours, and then drying at 300°C Calcined for 5 hours to prepare a modified alumina carrier. The above-mentioned modified alumina carrier is impregnated with nickel and gallium mixed aqueous solution of nickel nitrate and gallium nitrate with molar concentrations of 0.5mol / L and 1mol / L respectively by unsaturated spray impregnation method, the impregnation temperature is 50°C,...

example 2

[0028] Weigh commercially available alumina, saturate spray and impregnate alumina with a mass concentration of 20% ammonium acetate aqueous solution, and immediately dry at 110°C for 0.5h after drying until the adsorption amount of ammonium acetate aqueous solution is the amount of saturated absorption solution of the alumina carrier 40%, aged at 80°C for 4 hours, dried at 120°C for 8 hours, and then calcined at 400°C for 3 hours to obtain a modified alumina carrier. The above-mentioned modified alumina carrier is impregnated with nickel nitrate and gallium nitrate mixed aqueous solutions with nickel and gallium molar concentrations of 1.5 mol / L and 3 mol / L respectively by unsaturated spray impregnation method. It is 40% of the amount of the saturated absorption solution of the alumina carrier, dried at 90°C for 10h, and calcined at 900°C for 4h. The unsaturated carrier after roasting is sprayed and dipped in morphine aqueous solution. The spray volume of morphine aqueous sol...

example 3

[0030] Except that 5% ammonium thiocyanate was added to the impregnated ferric nitrate aqueous solution, the rest were the same as in Example 1, and the prepared catalyst was recorded as C-3, and the evaluation results after 300 hours were shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com