anti-corrosion coating

An anti-corrosion coating and base material technology, applied in anti-corrosion coatings, epoxy resin coatings, alkali metal silicate coatings, etc., can solve problems such as weak mechanical strength, hidden dangers in production safety, and increased production costs, and achieve good corrosion resistance. , good adhesion, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

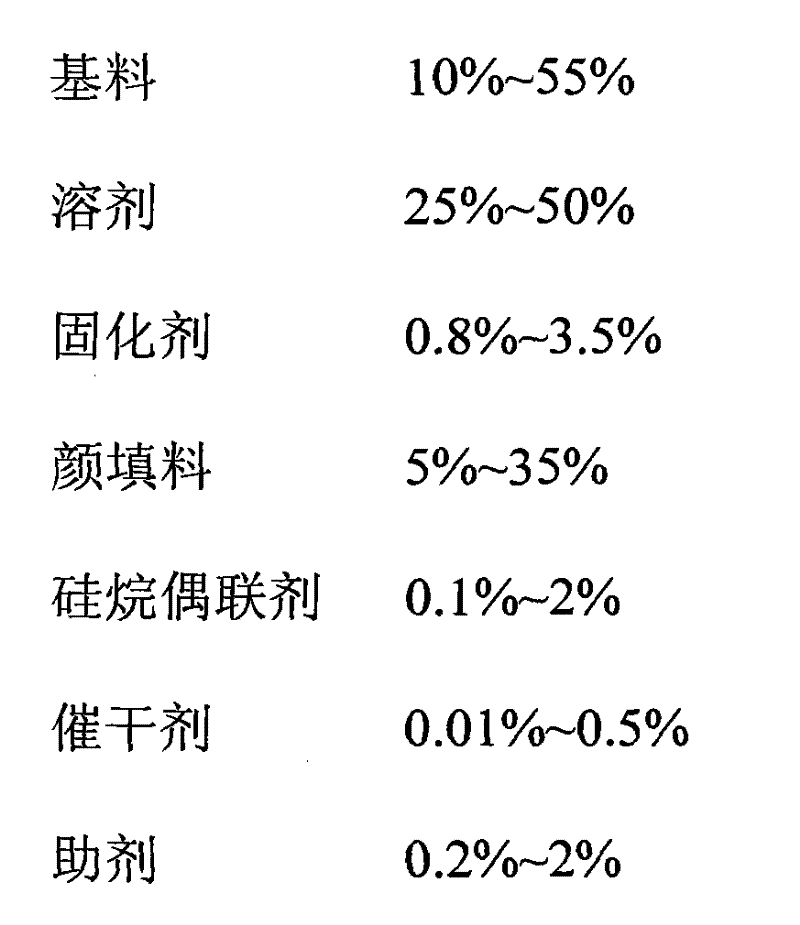

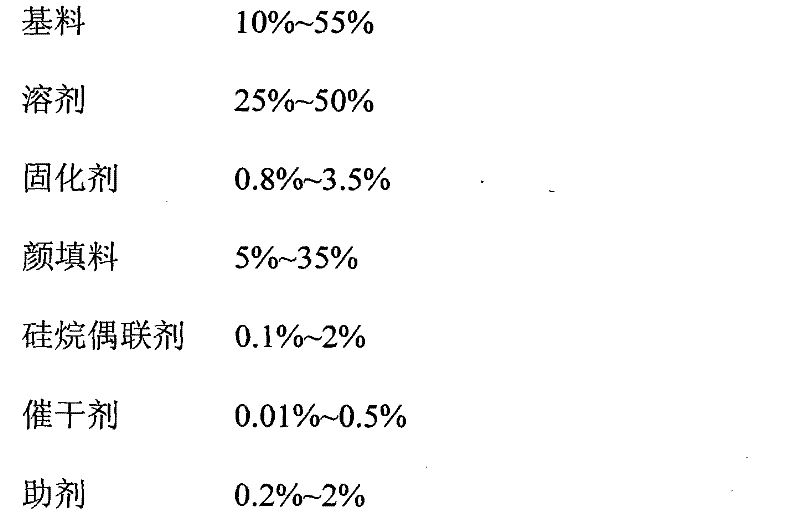

[0011] An anti-corrosion coating, including a base material, a solvent, a curing agent, pigments and fillers, a silane coupling agent, a drier, and an auxiliary agent. The base material in this embodiment is a modified silicone epoxy resin, and its weight percentage is 39.39% , this embodiment solvent is isopropanol, and its weight percentage is 50%, and the solidifying agent in this embodiment is polyamide 650, and its mass percentage is 3.5%, and the pigment filler in this embodiment is sepiolite powder, and its mass percentage The percentage is 5%, the silane coupling agent in the present embodiment is r-aminopropyltriethoxysilane, and the weight percentage is 0.1%, and the drier in the present embodiment is octoate zinc, and its weight percentage is 0.01%, the auxiliary agent in this embodiment is a film auxiliary agent, and its weight percentage is 2%.

Embodiment 2

[0013] An anti-corrosion coating, including a base material, a solvent, a curing agent, pigments and fillers, a silane coupling agent, a drier, and an auxiliary agent. The base material in this embodiment is a modified silicone epoxy resin, and its weight percentage is 46.45% , this embodiment solvent is isopropanol, and its weight percentage is 41%, and the solidifying agent in this embodiment is polyamide 650, and its mass percentage is 3.4%, and the pigment filler in this embodiment is sepiolite powder, and its mass percentage The percentage is 7%, the silane coupling agent in the present embodiment is r-aminopropyltriethoxysilane, and the weight percentage is 0.2%, and the drier in the present embodiment is octoate zinc, and its weight percentage is 0.05%, the auxiliary agent in this embodiment is a film auxiliary agent, and its weight percentage is 1.9%.

Embodiment 3

[0015] An anti-corrosion coating, including a base material, a solvent, a curing agent, pigments and fillers, a silane coupling agent, a drier, and an auxiliary agent. The base material in this embodiment is a modified silicone epoxy resin, and its weight percentage is 38.5% , this embodiment solvent is isopropanol, and its percentage by weight is 48%, and the solidifying agent in this embodiment is polyamide 650, and its mass percentage is 3.3%, and the pigment filler in this embodiment is sepiolite powder, and its mass percentage The percentage is 8%, and the silane coupling agent in the present embodiment is r-aminopropyltriethoxysilane, and the weight percentage is 0.3%, and the drier in the present embodiment is octoate zinc, and its weight percentage is 0.1%, the auxiliary agent in this embodiment is a film auxiliary agent, and its weight percentage is 1.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com