Water-borne polyurethane sponge strip coating and preparation method and application thereof

A technology of water-based polyurethane and sponge strips, which is used in the fields of chemical industry and coatings. It can solve the problems of application limitations, coating film water resistance, solvent resistance, poor physical and mechanical properties, and lack of chemical crosslinking, etc., and achieve excellent adhesion and durability. The effect of excellent pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

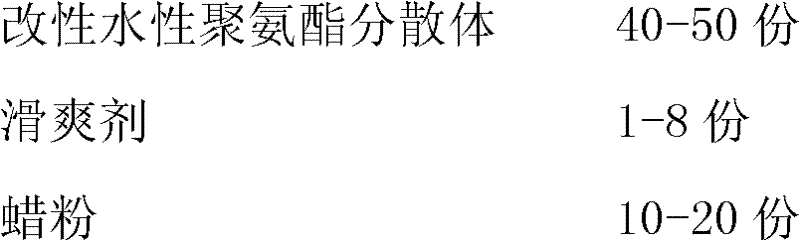

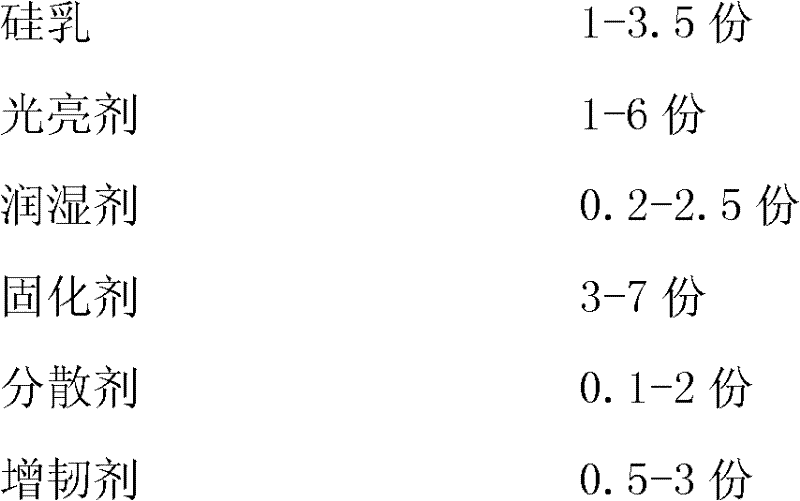

[0063] Preparation of Waterborne Polyurethane Sponge Coating

[0064] 1) In a sealed reactor equipped with a high-speed disperser, high-purity nitrogen protection, and a thermometer, add 200 g of polyoxypropylene diol and 40 g of water-dispersible polyisocyanate at -5 to 15 ° C, and stir and mix evenly;

[0065] 2) Then add 50g of α, ω-dihydroxypropyl polysiloxane dropwise through the dropping funnel under the condition of high-speed dispersion and stirring. After about 0.5h, add 35g of chain extender 1,4-butyl Glycol, stir evenly;

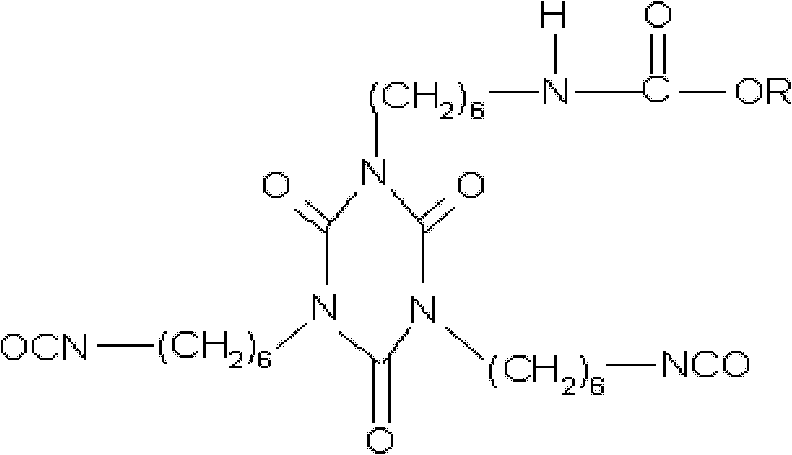

[0066] 3) Add stoichiometric water-dispersible polyisocyanate to make n(NCO):n(OH)=2.5:1 (molar ratio) in the system;

[0067] 4) Raise the temperature system to about 85-90°C for 3-5 hours and add N-acyl methyl taurine sodium, alcohol ether sodium sulfate and Span-20 at a weight ratio of 1:3:2 as the surface The activating agent is uniformly mixed to obtain the silicone copolymerized modified polyurethane emulsion PU-Si; the total amount of the...

Embodiment 2

[0084] The modified aqueous polyurethane dispersion was prepared by the method of Example 1, the difference being that the type of the surfactant was changed, and the other proportions and process conditions were the same. The coating appearance and film-forming stability were tested by GB9278-1988 and HG / T2458-1993 respectively, and the results are shown in Table 3:

[0085] Table 3 Effect of surfactant addition types on coating film

[0086]

Embodiment 3

[0088] The modified water-based polyurethane dispersion adopts aliphatic polyurethane dispersion or aromatic polyurethane dispersion respectively, and other proportions and process conditions are the same as in Example 1. The coating appearance and film-forming stability were tested by GB9278-1988 and HG / T2458-1993 respectively, and the results are shown in Table 4:

[0089] Table 4 Effect of using aliphatic and aromatic polyurethane dispersions on the coating film

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com