Composite material sweeping board, preparation method and application of composite material sweeping board

A composite material and vehicle board technology, which is applied in chemical instruments and methods, vehicle parts, transportation and packaging, etc., can solve the problems of difficult resin bonding and low melting point, and achieve the effects of weight reduction, simple preparation method and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

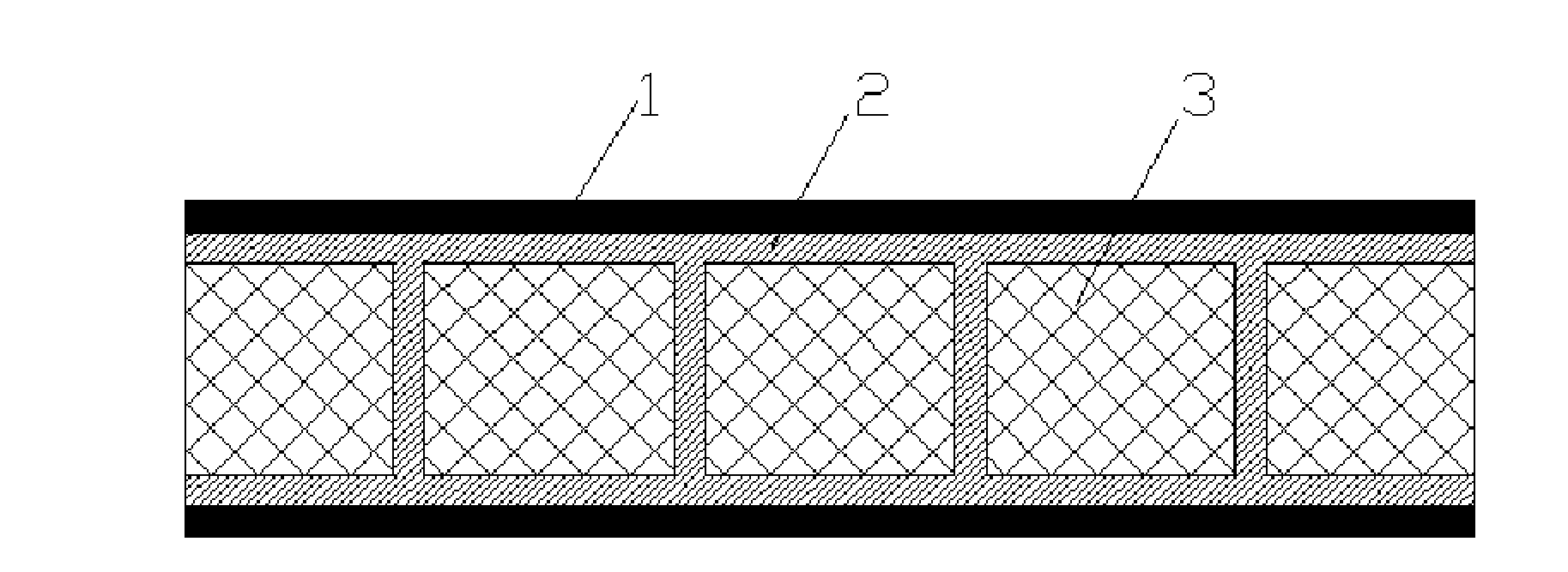

[0041] A light wear-resistant compartment floor for heavy-duty trucks is one of the composite material vehicle panels involved in the present invention, and its panel 1 (covered on the core material 2) is made of epoxy methacrylic vinyl resin and 1200dtex The ultra-high molecular weight polyethylene fiber unidirectional cloth is cured, the thickness of the panel is 2mm, and the fiber percentage is 60%. The core material 2 is cured by the same epoxy methacrylic vinyl resin and 48K carbon fiber unidirectional cloth. The thickness of the core material is 20mm, and the fiber percentage is 60%. Sandwich material 3 Balsa wood (Balsa wood), the interval between Balsa wood is 10mm. The production process is as follows: firstly, the UHMWPE fiber is surface-modified, and secondly, the modified UHMWPE fiber unidirectional fabric and carbon fiber unidirectional fabric are infiltrated with the prepared epoxy methacrylic vinyl resin system. , and then spread the ultra-high molecular weight...

Embodiment 2

[0043]A light-weight wear-resistant side panel for a heavy-duty truck is one of the light-weight wear-resistant composite material vehicle panels involved in the present invention, and its panel 1 (covered on the core material 2) is made of epoxy acrylic vinyl It is made of ester resin and 2640dtex ultra-high molecular weight polyethylene fiber bidirectional cloth, the thickness of the panel is 5mm, and the fiber percentage is 70%. The core material 2 is made by curing the same epoxy vinyl acrylate resin and 1200dtex glass fiber unidirectional cloth. Quality sandwich material 3 paulownia wood, the interval between paulownia wood is 20mm. The production process is as follows: first, surface modification of ultra-high molecular weight polyethylene fibers, secondly, infiltration of modified ultra-high molecular weight polyethylene fiber bidirectional cloth and glass fiber unidirectional cloth with the prepared epoxy vinyl acrylate resin system, Next, the ultra-high molecular wei...

Embodiment 3

[0045] A lightweight wear-resistant bottom plate for containers, the panel 1 (covered on the core material 2) is cured by isocyanate-modified vinyl ester resin and 1200dtex ultra-high molecular weight polyethylene fiber unidirectional cloth, and the thickness of the panel is 8mm. The fiber percentage is 60%. The core material 2 is formed by curing the same isocyanate-modified vinyl ester resin and 12K carbon fiber twill cloth, the thickness of the core material is 16mm, and the fiber percentage is 70%. And the middle of the core material 2 is placed with the lightweight sandwich material 3 paulownia wood with a thickness of 5 mm at intervals, and the interval between the paulownia woods is 10 mm. The production process is as follows: first, surface modification of ultra-high molecular weight polyethylene fibers, secondly, infiltration of modified ultra-high molecular weight polyethylene fiber unidirectional cloth and carbon fiber twill cloth with prepared isocyanate-modified v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com