Abrasion-proof portable electronic device casing

An electronic device, portable technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems that have not yet been found, the hardness of the material is not ideal, and it is difficult to meet the wear resistance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

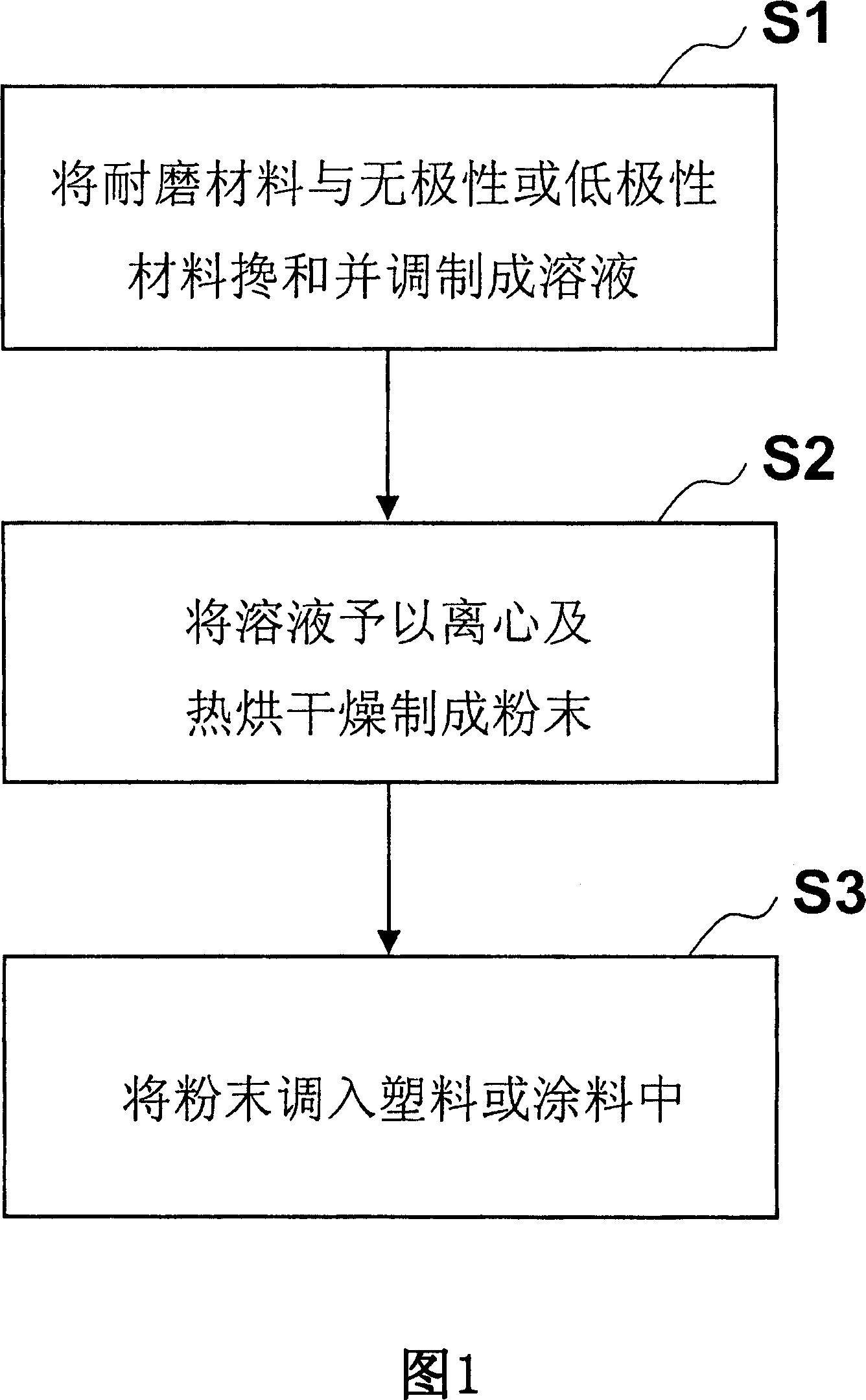

Image

Examples

Embodiment 1

[0036] The ratio of plastic: zirconium dioxide: zinc oxide = 98.5:1:0.5 is used to make the casing material. After testing, it is found that the hardness is as high as 5H, which is similar to or even surpasses that of magnesium-aluminum alloy. And under normal visible light irradiation, the bactericidal effect of Staphylococcus aureus can reach more than 99.5%. In addition, the zinc oxide component also helps to resist ultraviolet rays and prevent the plastic from disintegrating.

Embodiment 2

[0038] The ratio of plastic: zirconium dioxide: zinc oxide: calcium carbonate = 98.5:1:0.25:0.25 is used to make the casing material. After testing, it is found that the hardness is also as high as 5H, which is similar to or even surpasses that of magnesium-aluminum alloy. And the bactericidal function is similar to that of Example 1.

Embodiment 3

[0040] Using the ratio of plastic: zirconia: zinc oxide: silicon dioxide = 98.5: 0.5: 0.4: 0.6 to make the casing material, it is found that the hardness is about 4H, which is far superior to the existing plastic materials, and there are obvious cracks on the surface. Smoothness, more scratch-resistant.

[0041] The silicon dioxide was replaced by molybdenum disulfide, and the smoothness was found to be similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com