Stiffened timber floor and the manufacturing method thereof

A technology for laminate flooring and flooring, applied in laminate flooring and its manufacturing field, can solve the problems of easily hurting feet, fast wear, affecting the appearance of the floor, etc., and achieve the effects of convenient flooring, long service life and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

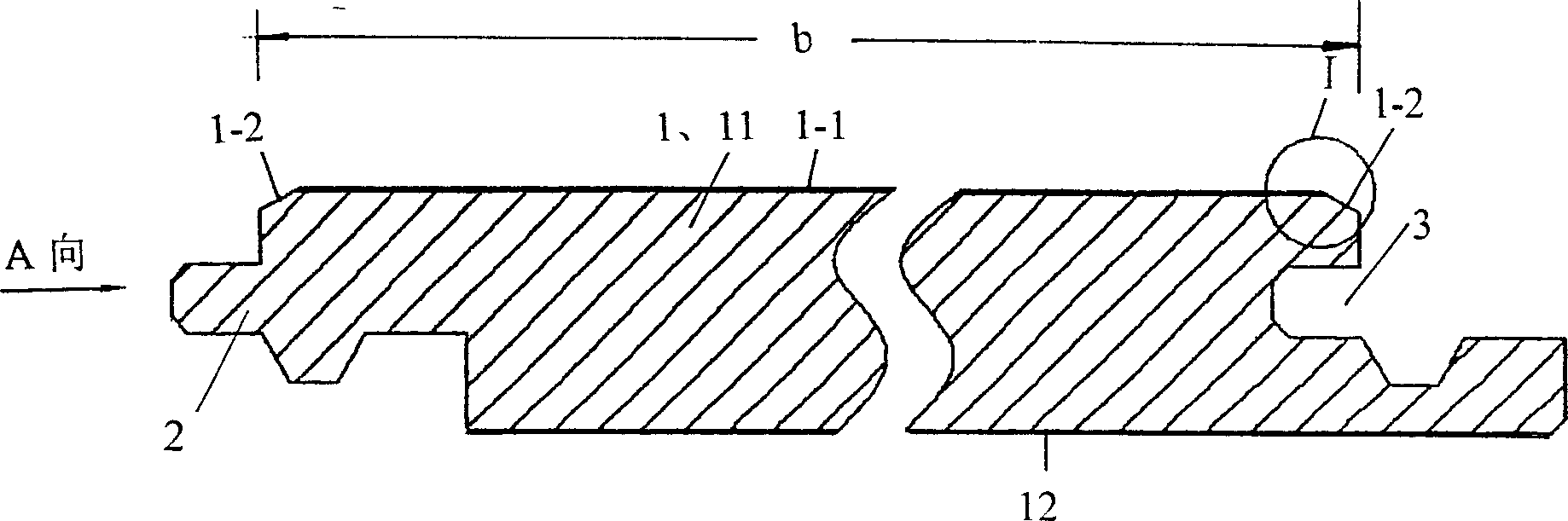

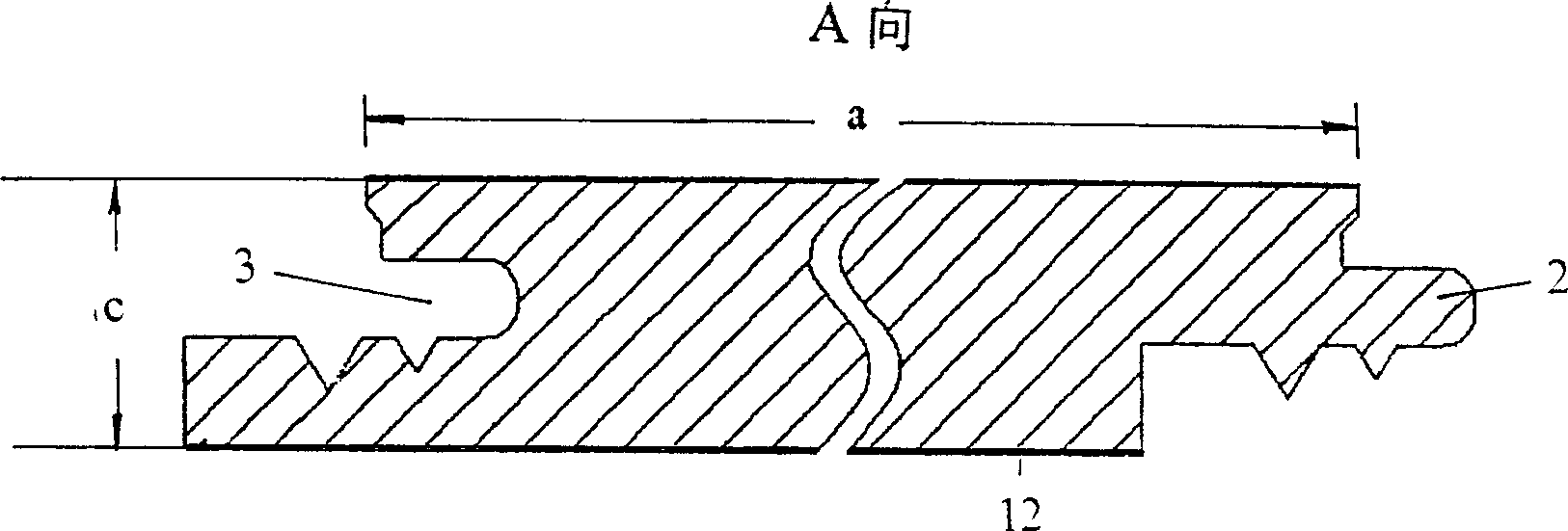

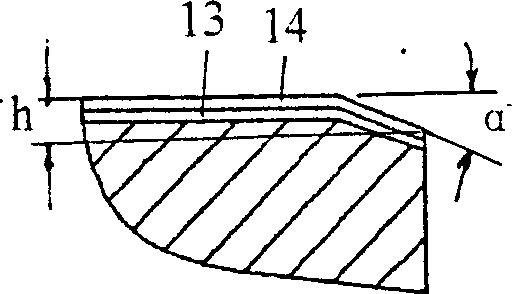

[0038] See Figure 1 to Figure 3 , Embodiment 1 has a floor body 1 and tenons 2 and grooves 3 on the four sides of the floor body 1. The floor body 1 has a fiberboard 11 and a balance paper layer 12 arranged on the bottom surface of the fiberboard 11. The balance paper 120 is composed of base paper through the main components. It is made by impregnating melamine glue; the upper surface of the floor body 1 is composed of a walking surface 1-1 parallel to the bottom surface and inclined surfaces 1-2 on both sides of the walking surface, and the upper surface of the fiberboard 11 is provided with wood grains in sequence The paper layer 13 and the wear-resistant paper layer 14 are bonded sequentially. The fiberboard 11 is a medium-density fiberboard or high-density fiberboard; the wear-resistant paper 140 is sprayed with aluminum oxide particles on the base paper and then passed through a glue whose main component is melamine. It is prepared after impregnation; the length a of the...

Embodiment 2

[0042] The diagram of embodiment 2 refers to figure 1 , figure 1 For a partial enlargement, see Figure 12 . Embodiment 2 has a floor body 1 and tenons 2 and grooves 3 on both sides of the floor body 1. The floor body 1 has a fiberboard 11 and a balance paper layer 12 arranged on the bottom surface of the fiberboard 11. The upper surface of the floor body 1 is formed by a The parallel walking surface 1-1 is composed of inclined surfaces 1-2 on both sides of the walking surface, and the walking surface 1-1 on the upper surface of the fiberboard 11 is provided with a wood grain paper layer 13-1 and a wear-resistant paper layer 14-1 in sequence, And bonded sequentially, the inclined surfaces 1-2 on the edges of both sides are bonded and fixed with a wood grain paper layer 13-2, and a resin varnish layer 14-2 is cured on the wood grain paper layer 13-2. The length of the embodiment floor is 1215mm, the width is 138mm, and the thickness is 8.2mm. The inclination angle α of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com