A kind of differential speed quenching device and process method of casting groove for mining scraper machine

The technology of a quenching device and process method, which is applied in the field of channel side casting, can solve the problems of inability to achieve hardness and performance, too fast wear of the channel side matrix, and insufficient toughness of the push ear, so as to shorten the holding time, improve the performance of the channel side, and improve Effect of mechanical properties and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

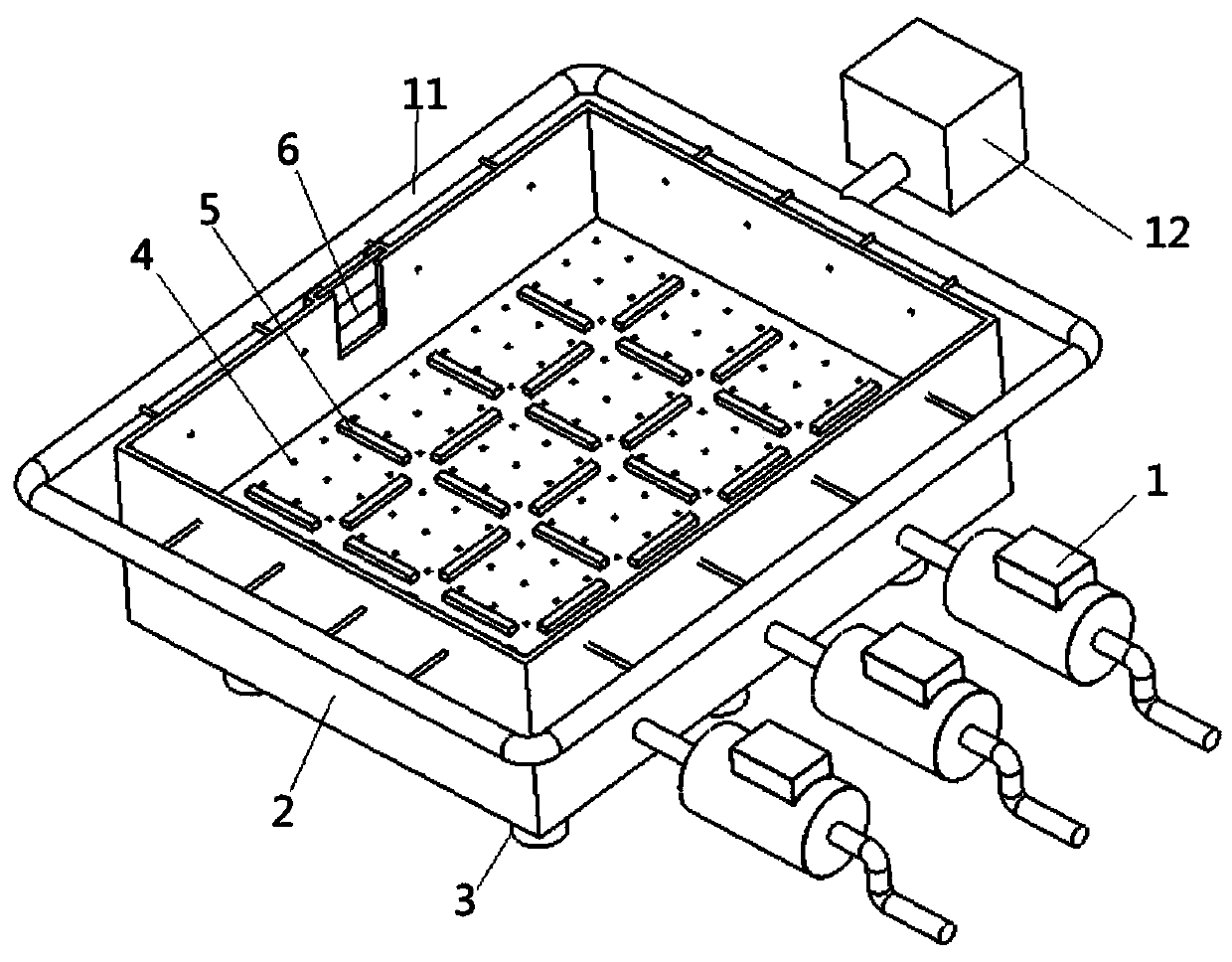

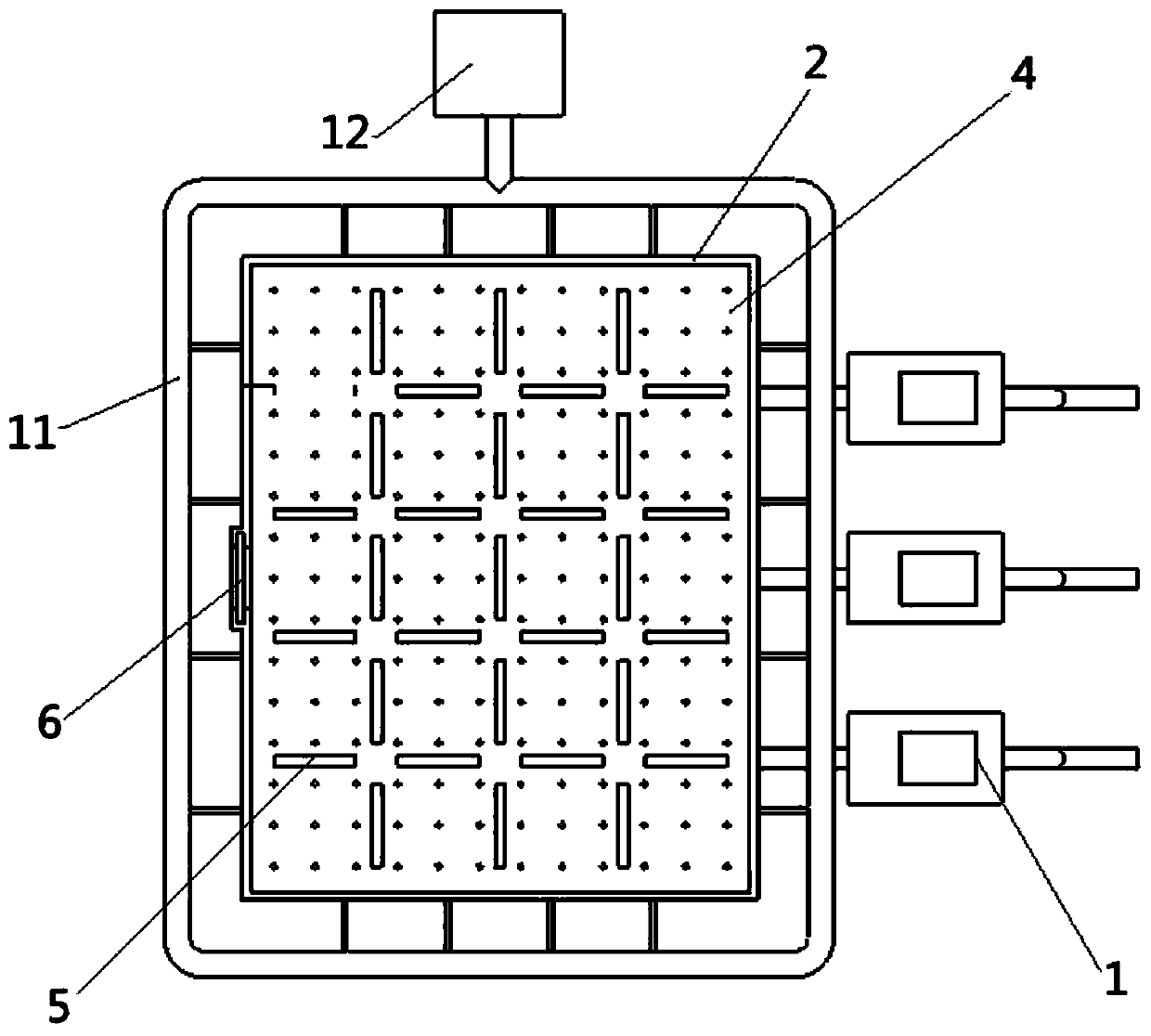

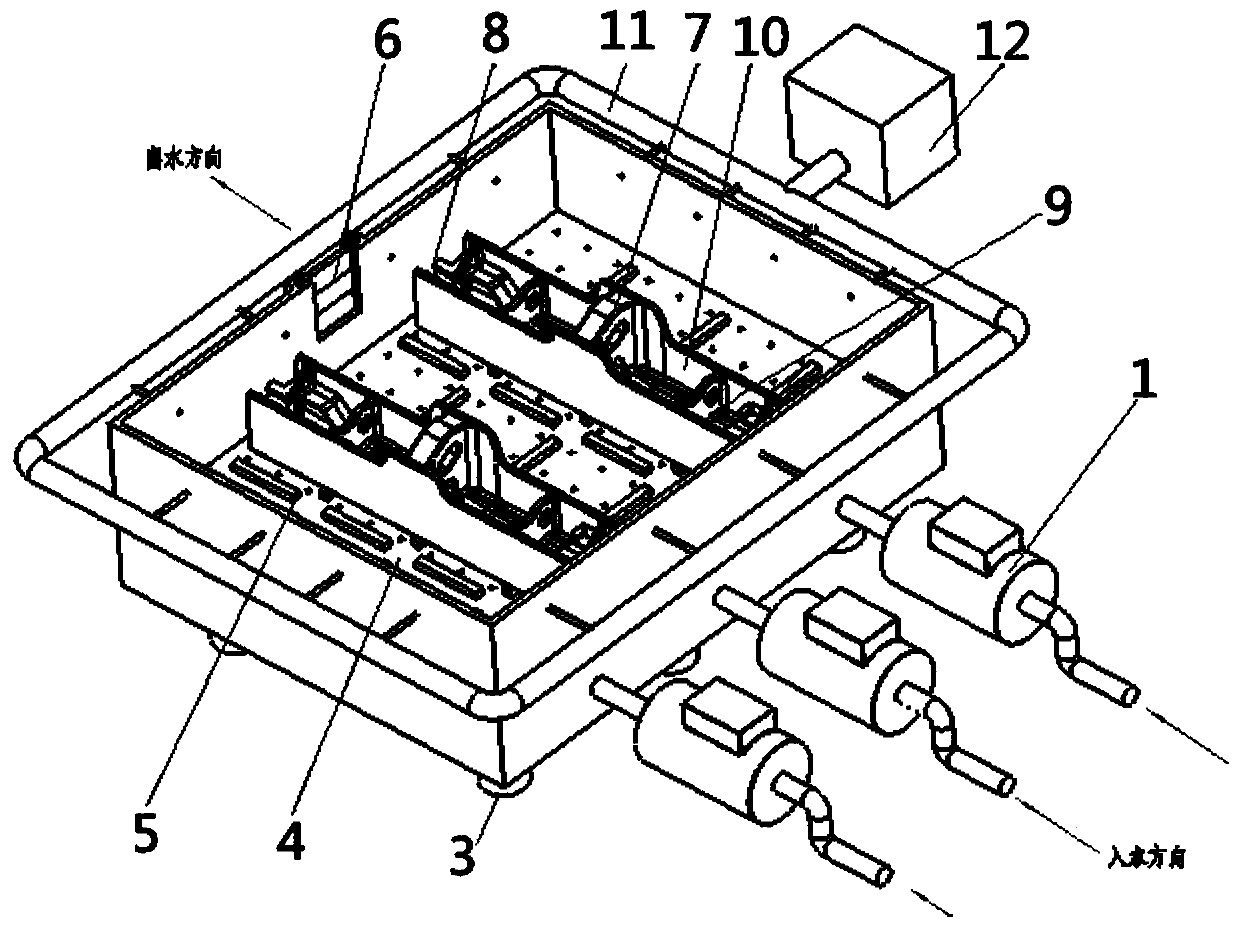

[0033] Embodiment 1: first turn on three water pumps, fill the water tank 2 with water, and set a water level partition 6 at the water outlet according to the height of the water quenching part of the side of the tank to determine the water level of the tank;

[0034] According to the height and shape of the water column formed by the hydraulic orifice plate, the flow and pressure of the water pump 1 are adjusted as long as the height of the water column does not exceed the water level of the tank;

[0035] When heating, heat the side of the tank in a resistance furnace, the holding temperature is 920°C, and after holding the heat for 90 minutes, it is quenched out of the furnace;

[0036] When quenching, the tank side is hoisted by pushing the 7 lugs upward, and slowly enter the water horizontally until the tank side base, convex end and concave end are all submerged in the water, and the water temperature during quenching is ≤30°C. The 7 parts of the moving ear are exposed t...

Embodiment 2

[0042] Embodiment 2: first turn on three water pumps, fill the water tank 2 with water, and set a water level partition 6 at the water outlet according to the height of the water quenching part of the side of the tank to determine the water level of the tank;

[0043] According to the height and shape of the water column formed by the hydraulic orifice plate, the flow and pressure of the water pump 1 are adjusted as long as the height of the water column does not exceed the water level of the tank;

[0044] Heating the side of the tank in a resistance furnace, the holding temperature is 920°C, and after holding the heat for 100 minutes, it is quenched out of the furnace;

[0045] When quenching, the side of the tank is hoisted with the push lug 7 facing upwards, and slowly enter the water horizontally until the base of the side of the tank, the convex end and the concave end are all submerged in the water, and the water temperature during the quenching process is ≤30°C. The 7 pa...

Embodiment 3

[0051] Embodiment 3: first turn on three water pumps, fill the water tank 2 with water, and set a water level partition 6 at the water outlet according to the height of the water quenching part of the side of the tank to determine the water level of the water tank;

[0052] According to the height and shape of the water column formed by the hydraulic orifice plate, the flow and pressure of the water pump 1 are adjusted as long as the height of the water column does not exceed the water level of the tank;

[0053] Heating the side of the tank in a resistance furnace, the holding temperature is 920°C, and after holding the heat for 120 minutes, it is quenched out of the furnace;

[0054] When quenching, the side of the tank is hoisted with the push lug 7 facing upwards, and slowly enter the water horizontally until the base of the side of the tank, the convex end and the concave end are all submerged in the water, and the water temperature during the quenching process is ≤30°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com