Ion exchange resin modified polyvinylidene fluoride (PVDF) charcoal electrode and preparation method thereof

A technology of ion exchange resin and carbon electrode, which is applied in the field of fresh water treatment technology, can solve the problems of reduced electrode adsorption capacity by redox current, insufficient improvement of hydrophilicity, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

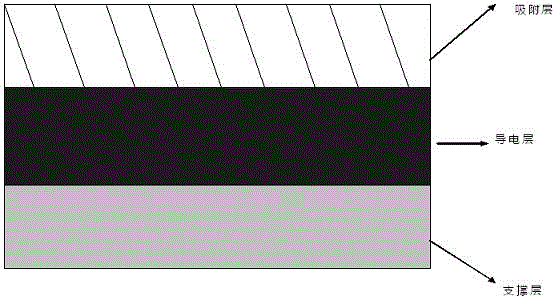

Image

Examples

Embodiment 1

[0049] 1: Pretreatment of activated carbon powder, graphite powder, and cation exchange resin powder: Soak activated carbon powder and graphite powder in distilled water for 24 hours, then heat and dry at 120°C for 24 hours. The pretreatment steps of the ion exchange resin powder are: soak the washed cation resin powder in 2% NaOH solution which is about twice the volume of the resin for 4 hours, then drain it, and then wash it with water until the discharge liquid is close to neutral. Add 5% HCl twice the volume of the resin and soak for 4 hours to drain it, then wash it with clean water to be close to neutral.

[0050] Two: Mix 40g of graphite powder and 4g of PVDF to obtain a mixture, dissolve the mixture in 52ml N, N dimethylacetamide to obtain a slurry, then stir at a speed of 300rd / min for 12h, and coat the stirred slurry on a plexiglass plate , 60 ℃ drying, 70 ℃ vacuum firing made graphite conductive layer.

[0051] Three: Mix 40g of activated carbon powder, 4g of PVD...

Embodiment 2

[0053] One: Activated carbon powder, graphite powder, and cation exchange resin powder are pretreated: soak activated carbon powder and graphite powder in distilled water for 24 hours, then heat and dry at 120°C for 24 hours. The pretreatment steps of the ion exchange resin powder are: soak the washed cation resin powder in 2% NaOH solution about twice the volume of the resin for 4 hours, then drain it, and then wash it with water until the discharge liquid is close to neutral. Add 5% HCl twice the volume of the resin and soak for 4 hours to drain it, then wash it with clean water to be close to neutral.

[0054] Two: Mix 40g of graphite powder and 16g of PVDF to obtain a mixture, dissolve the mixture in 52ml N, N dimethylacetamide to obtain a slurry, then stir at a speed of 400rd / min for 15h, and coat the stirred slurry on a plexiglass plate , Dry at 60°C, and vacuum burn at 70°C to form a graphite conductive layer.

[0055] Three: Mix 40g of activated carbon powder, 16g of...

Embodiment 3

[0057] One: Activated carbon powder, graphite powder, and cation exchange resin powder are pretreated: soak activated carbon powder and graphite powder in distilled water for 24 hours, then heat and dry at 120°C for 24 hours. The pretreatment steps of the ion exchange resin powder are: soak the washed cation resin powder in 2% NaOH solution about twice the volume of the resin for 4 hours, then drain it, and then wash it with water until the discharge liquid is close to neutral. Add 5% HCl twice the volume of the resin and soak for 4 hours to drain it, then wash it with clean water to be close to neutral.

[0058] Two: Mix 40g of graphite powder and 8g of PVDF to obtain a mixture, dissolve the mixture in 52ml of N, N dimethylacetamide to obtain a slurry, then stir at a speed of 300rd / min for 15h, and coat the stirred slurry on organic glass The board was dried at 60°C and vacuum fired at 70°C to form a graphite conductive layer.

[0059] Three: Mix 40g of activated carbon pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com