Method for preparing shell structure imitated steel-based coating on aluminium substrate

A technology of imitating shells and aluminum substrates, which is applied in coatings, metal material coating processes, fusion spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

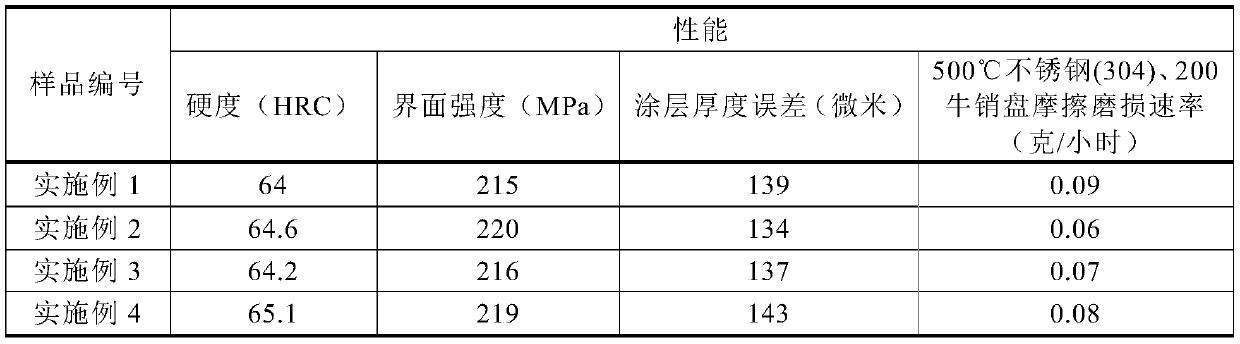

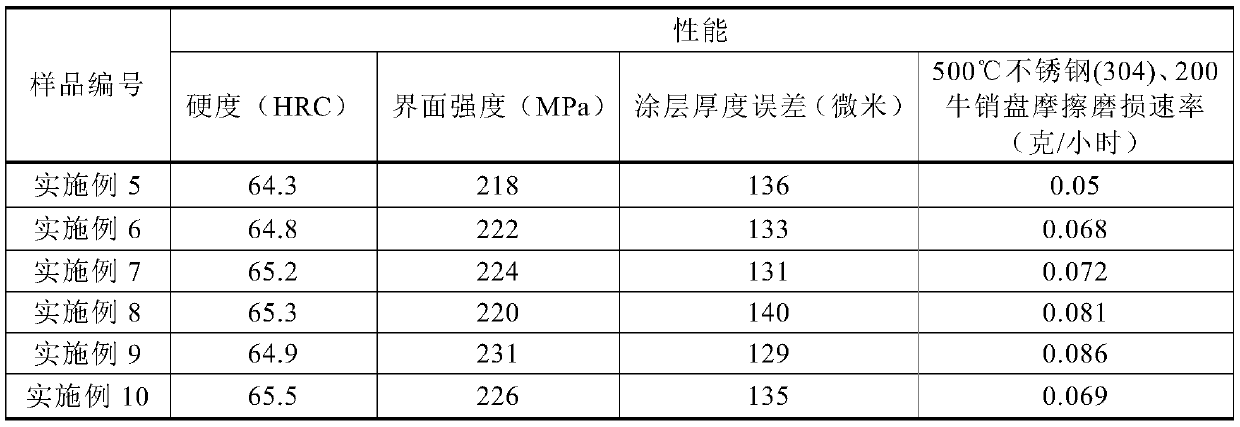

Examples

Embodiment 1

[0022] 1) The iron-aluminum alloy foil with a mass percentage of aluminum element of 6% and a thickness of 0.01 mm and a 304 stainless steel foil with a thickness of 0.02 mm are laminated and spread on the surface of the aluminum substrate. The lateral dimension of the foil is 1 cm larger than the coating size. Put it in a high-vacuum heating furnace for foil-substrate sticking treatment, vacuum degree ≤ 10 -3 , the sticking treatment temperature is 275°C, and the coating preform is obtained;

[0023] 2) Using atomized 304 stainless steel powder with a particle size of 45 microns and granulated silicon carbide powder with a particle size of 62 microns as raw materials, a steel-bonded silicon carbide cermet layer was prepared on the surface of the coating preform by supersonic plasma double-spray technology, two The included angle of the spray gun is 60 degrees, the working gas is propane, the voltage and current are 180 volts and 360 amperes respectively;

[0024] 3) Bond the...

Embodiment 2

[0026] 1) The iron-aluminum alloy foil with a mass percentage of aluminum element of 7% and a thickness of 0.02 mm and a 304 stainless steel foil with a thickness of 0.03 mm are laminated and spread on the surface of the aluminum substrate, and the lateral dimension of the foil is 1 cm larger than the coating size. Put it in a high-vacuum heating furnace for foil-substrate sticking treatment, vacuum degree ≤ 10 -3 , the sticking treatment temperature is 288°C, and the coating preform is obtained;

[0027] 2) Using atomized 304 stainless steel powder with a particle size of 47 microns and granulated silicon carbide powder with a particle size of 64 microns as raw materials, a steel-bonded silicon carbide cermet layer was prepared on the surface of the coating preform by supersonic plasma double-spray technology, two The included angle of the spray gun is 60 degrees, the working gas is propane, the voltage and current are 180 volts and 360 amperes respectively;

[0028] 3) Bond...

Embodiment 3

[0030] 1) The iron-aluminum alloy foil with a mass percentage of 8% aluminum element and a thickness of 0.03 mm and a 304 stainless steel foil with a thickness of 0.04 mm are laminated and spread on the surface of the aluminum substrate. The lateral dimension of the foil is 1 cm larger than the coating size. Put it in a high-vacuum heating furnace for foil-substrate sticking treatment, vacuum degree ≤ 10 -3 , the sticking treatment temperature is 298°C, and the coating preform is obtained;

[0031] 2) Using atomized 304 stainless steel powder with a particle size of 49 microns and granulated silicon carbide powder with a particle size of 66 microns as raw materials, a steel-bonded silicon carbide cermet layer was prepared on the surface of the coating preform by supersonic plasma double-spray technology, two The included angle of the spray gun is 60 degrees, the working gas is propane, the voltage and current are 180 volts and 360 amperes respectively;

[0032] 3) Bond the 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial bonding strength | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com