Electronic equipment, rotating shaft, layered composite material and manufacturing method of layered composite material

A layered composite material and composite material technology, applied in the terminal field, can solve the problems of poor overall cooling effect of notebook computers, anti-drop performance of the shaft, poor wear resistance and thermal conductivity, wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The terms used in the embodiments of the application are only used to explain the specific embodiments of the application, and are not intended to limit the application. The implementation of the embodiments of the application will be described in detail below with reference to the accompanying drawings.

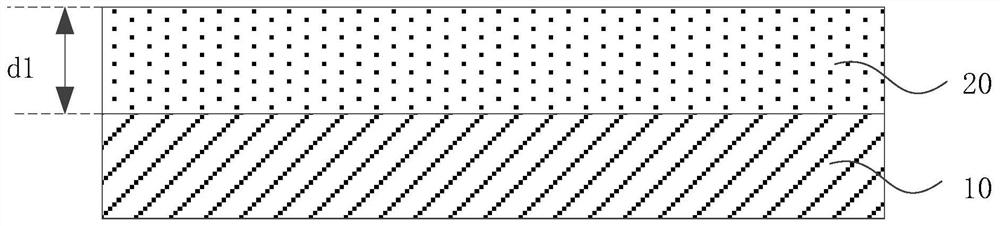

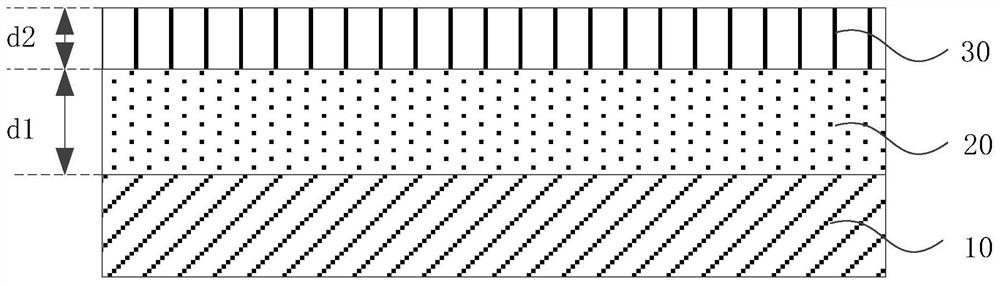

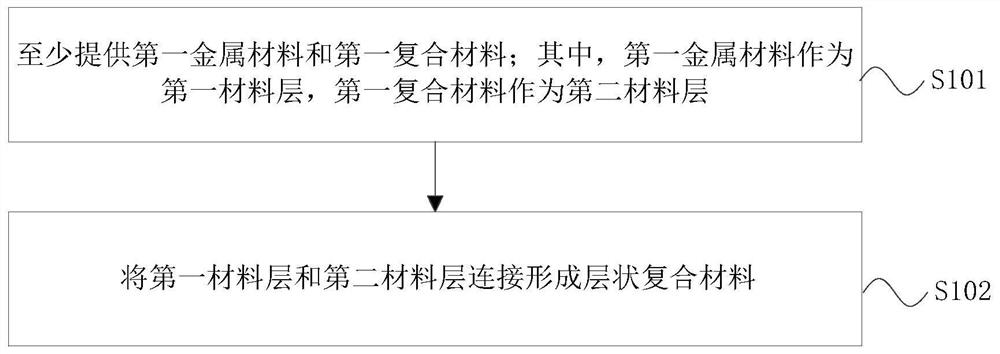

[0058] Such as figure 1 As shown, the embodiment of the present application provides a layered composite material, which may include: at least two material layers (i.e. figure 1 The first material layer 10 and the second material layer 20, the second material layer 20 is adjacent to the first material layer 10), wherein, the first material layer 10 in at least two material layers can adopt the first metal material The yield strength of the first metal material can be greater than 200MPa, and the elongation of the first metal material can be greater than 6%. In this way, the high yield strength and high elongation of the first metal material can ensure the drop resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com