A kind of aluminum bronze and preparation method thereof

An aluminum bronze, hot extrusion technology, applied in the field of copper alloys, can solve the problems of unbalance, inability to meet, and aluminum bronze cannot be effectively controlled, and achieve the effect of improving corrosion resistance and comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

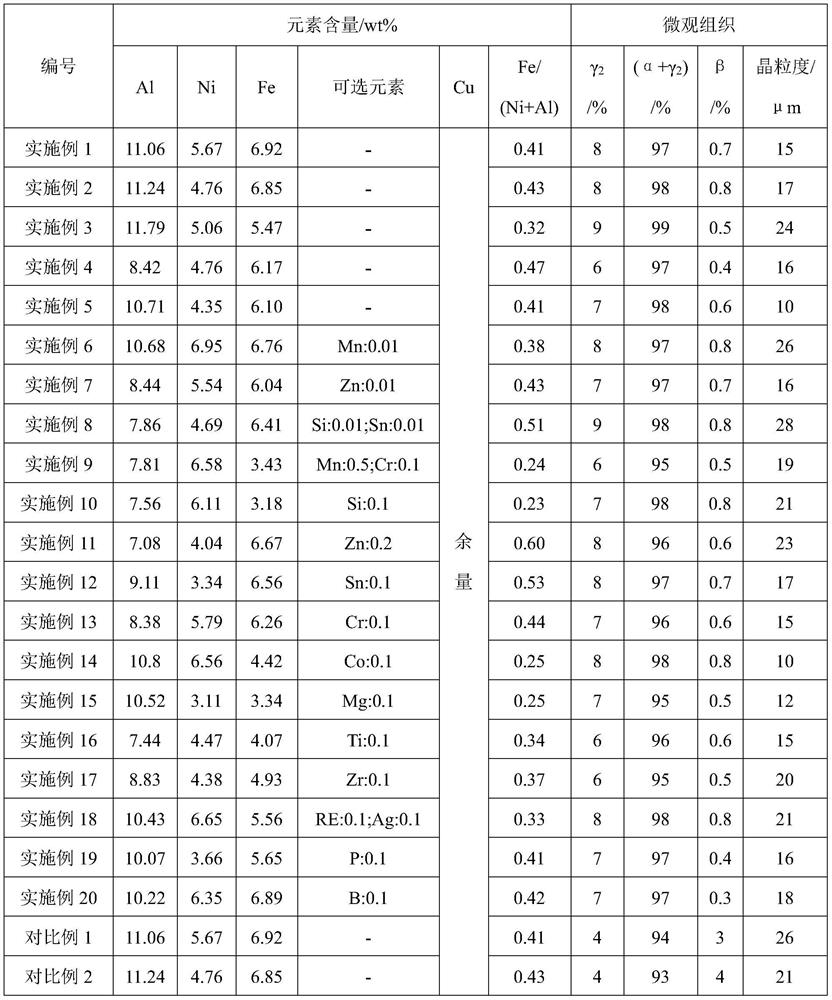

[0032] Below in conjunction with embodiment the present invention is described in further detail.

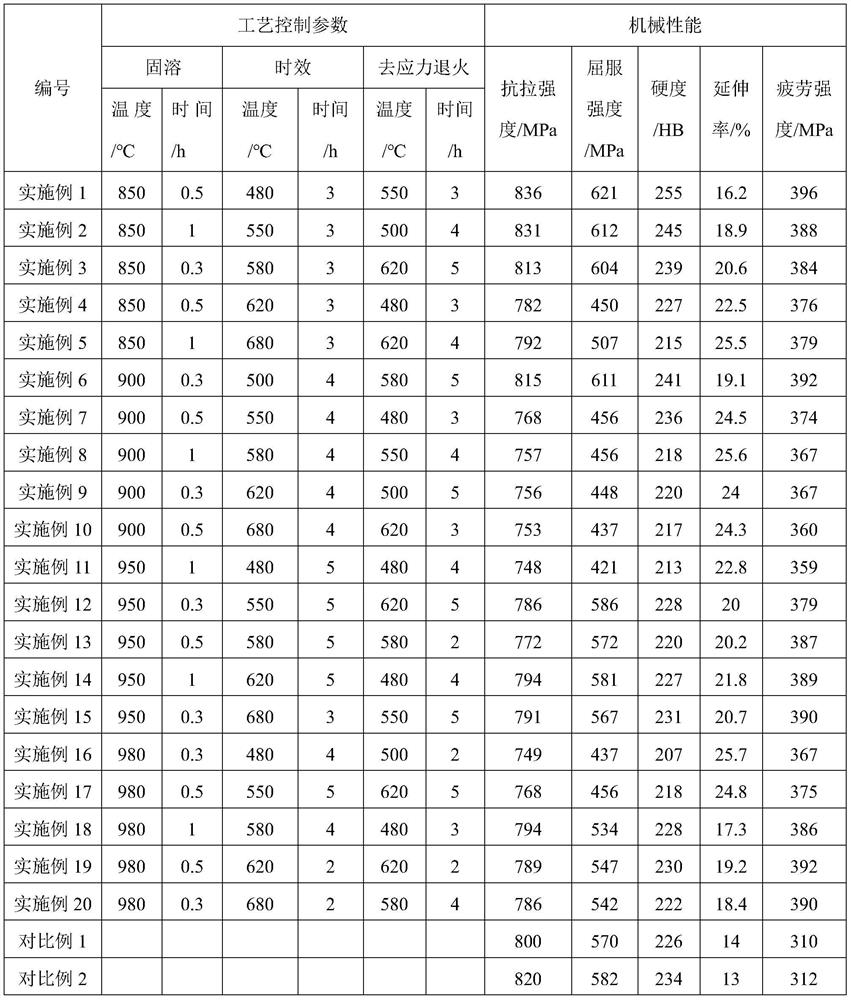

[0033] Examples 1 to 20 are the components of the aluminum bronze of the present invention. The specific components are shown in Table 1. They are prepared according to the method of the present invention. The process flow is: casting→hot extrusion→solid solution→aging→stretching→stress relief annealing→straightening; The parameters are controlled as follows:

[0034] Casting: batching according to the ingredients in Examples 1-20, melting, and then producing ingots through horizontal continuous casting, the casting temperature is controlled at 1100-1450 °C;

[0035] Hot extrusion: After the ingot is cooled, it is heated to 600-900°C for hot extrusion, and the extrusion ratio is controlled at 16-400;

[0036] Solid solution: The extruded product is placed in a heating furnace for solid solution treatment at a temperature of 800-1000°C for 0.3-1 hour, and then water-cooled;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com