Color printing device based on metal nano brick array and printing method

A metal nano and color printing technology, applied in the field of micro-nano optics and polarized optics, can solve problems such as difficult photon integration, difficult generation of image information, complex process, etc., and achieve the effect of rich colors, simple structure, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

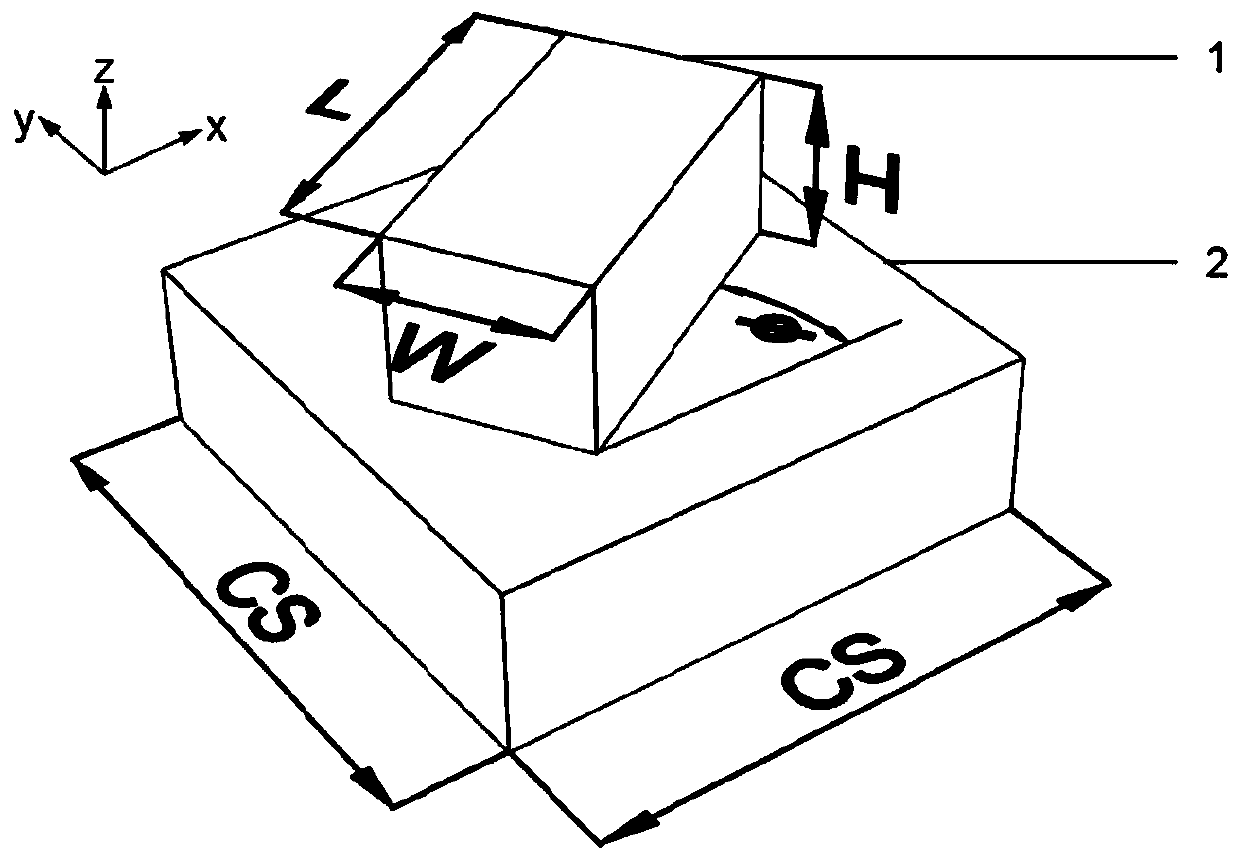

[0044]This embodiment provides a micro-nano bandpass polarizer based on a metal nano-brick array structure, and it is applied in color nano-printing technology. The metal nano-brick array consists of a substrate and metal nano-bricks etched on the substrate. The array is composed of two layers, and through the design, the functions of filtering and modulating light intensity can be realized at the same time, and it can be used for color image printing and display.

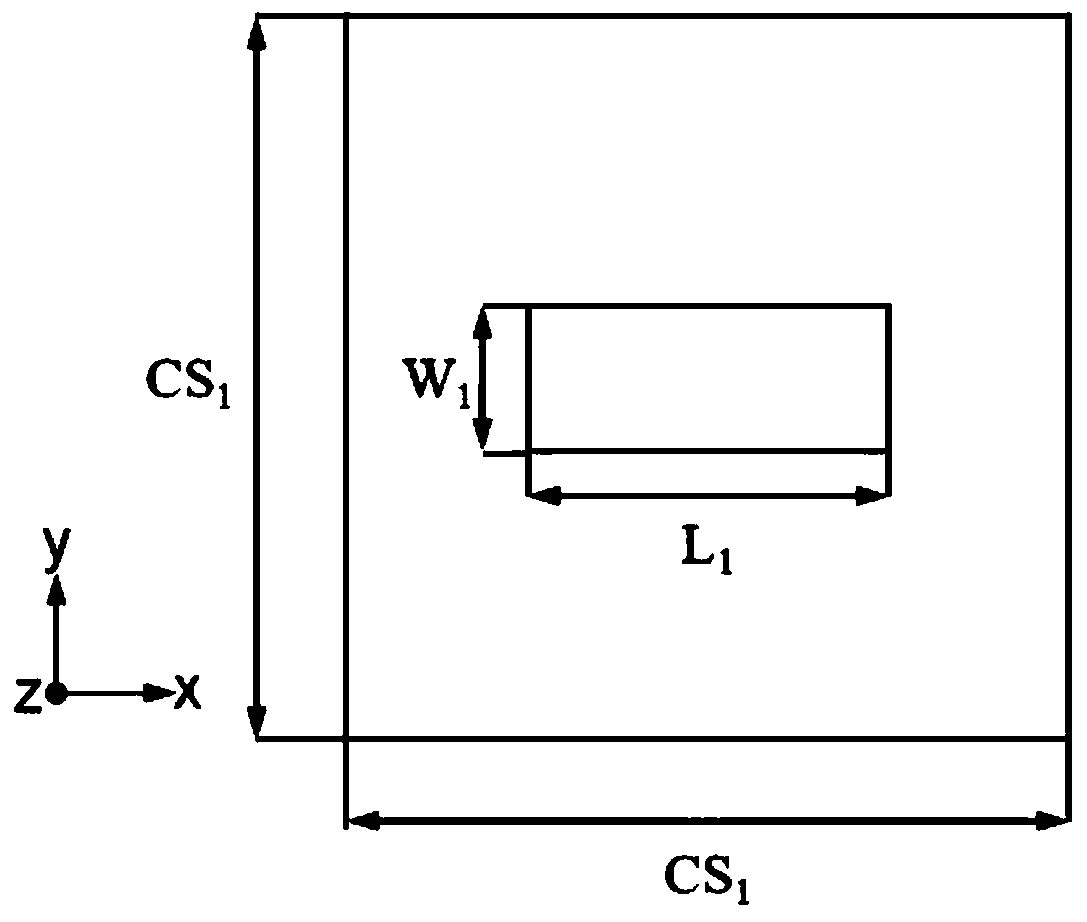

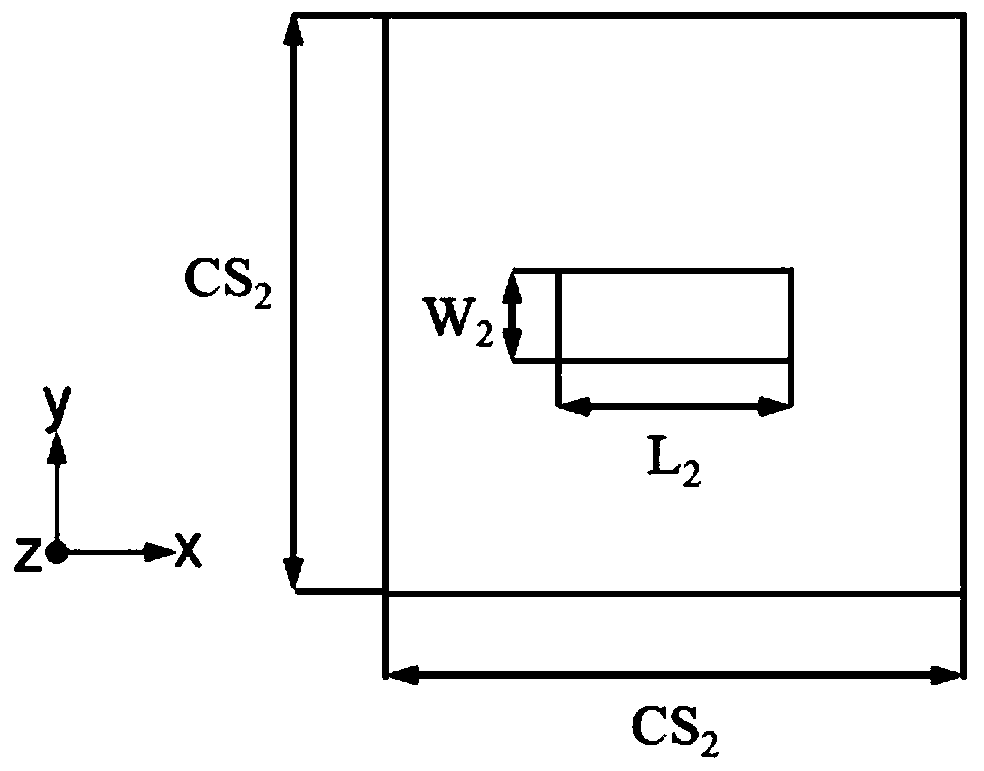

[0045] In this embodiment, the fused silica material is used as the substrate, and the metal aluminum material is used to etch the nano-brick structure. The single nano-brick unit structure is as follows figure 1 As shown, the metasurface material is composed of 1-nanometer bricks and 2-substrates, where the substrate of the unit structure is a square working surface with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com