Alloy material for power mechanical parts and preparation method thereof

A technology of alloy materials and power machinery, which is applied in the field of alloy materials for power machinery parts and its preparation, can solve the problems of inclusions on the surface of pores, difficulty in secondary molding, and bronze ingots that cannot meet the demand, so as to reduce porosity, avoid cracking, The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

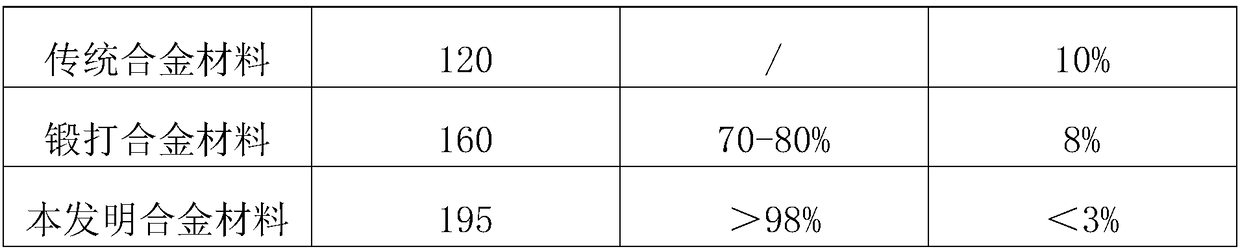

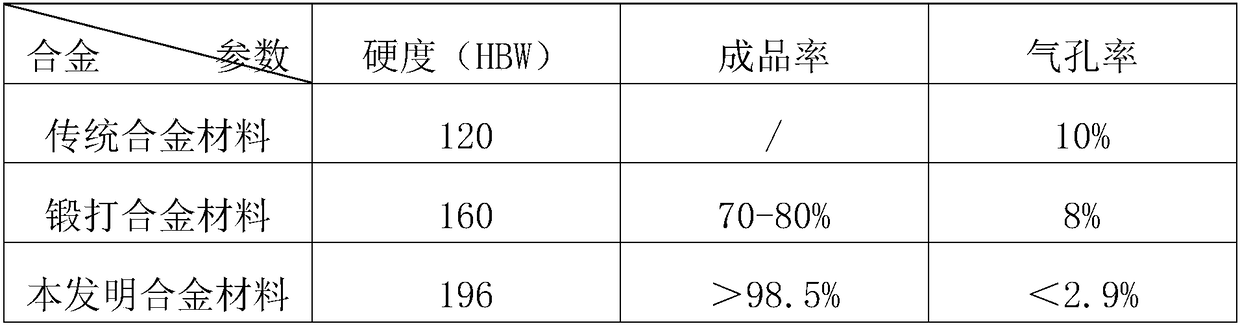

Embodiment 1

[0029] An alloy material for power machinery parts. The components of the alloy material are as follows by weight percentage: titanium boride: 3%, aluminum: 17%, iron: 10%, manganese: 3%, nickel: 4%, lanthanum: 2% %, tin: 1%, zinc: 1%, silicon: 0.5%, phosphorus: 0.5%, and the balance is copper.

[0030] 1) Put zinc, iron, manganese, nickel, silicon, and phosphor copper in a power frequency electric furnace according to the weight ratio, heat to 1150°C to completely melt and keep it warm to form a multi-element alloy solution;

[0031] 2) According to the weight ratio, aluminum and tin are placed in a crucible furnace for melting, the melting temperature is 680°C, and the melting time is 20 minutes to form an aluminum-tin alloy;

[0032] 3) Add lanthanum to the multi-element alloy solution being kept warm according to the weight ratio, turn on the vibrating device and the stirring device, the vibration frequency of the vibrating device is: 15 times / second; the stirring rate of ...

Embodiment 2

[0042] An alloy material for power machinery parts. The components of the alloy material by weight percentage are: titanium boride: 3.75%, aluminum: 18%, iron: 10.75%, manganese: 0.75%, nickel: 4.75%, lanthanum: 2.75% %, tin: 1.75%, zinc: 2.25%, silicon: 1%, phosphorus: 0.75%, and the balance is copper.

[0043] 1) Put zinc, iron, manganese, nickel, silicon, and phosphor copper in a power frequency electric furnace according to the weight ratio, heat to 1150°C to completely melt and keep it warm to form a multi-element alloy solution;

[0044] 2) According to the weight ratio, aluminum and tin are placed in a crucible furnace for melting, the melting temperature is 680°C, and the melting time is 23 minutes to form an aluminum-tin alloy;

[0045] 3) Add lanthanum to the multi-element alloy solution being kept warm according to the weight ratio, turn on the vibrating device and the stirring device, the vibration frequency of the vibrating device is: 15 times / second; the stirring...

Embodiment 3

[0054] An alloy material for power machinery parts. The components of the alloy material are as follows by weight percentage: titanium boride: 4.5%, aluminum: 19%, iron: 11.5%, manganese: 4.5%, nickel: 5.5%, lanthanum: 3.5% %, tin: 2.5%, zinc: 3.5%, silicon: 1.5%, phosphorus: 1%, and the balance is copper.

[0055] 1) Put zinc, iron, manganese, nickel, silicon, and phosphor copper in a power frequency electric furnace according to the weight ratio, heat to 1150°C to completely melt and keep it warm to form a multi-element alloy solution;

[0056] 2) According to the weight ratio, aluminum and tin are placed in a crucible furnace for melting, the melting temperature is 680°C, and the melting time is 25 minutes to form an aluminum-tin alloy;

[0057] 3) Add lanthanum to the multi-element alloy solution being kept warm according to the weight ratio, turn on the vibrating device and the stirring device, the vibration frequency of the vibrating device is: 15 times / second; the stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com