Cooling system for plastic corrugated pipe equipment

A cooling system and bellows technology, which is applied to tubular items, other household appliances, household appliances, etc., can solve the problems of low cooling efficiency, high failure rate, limiting the production speed of pipes, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

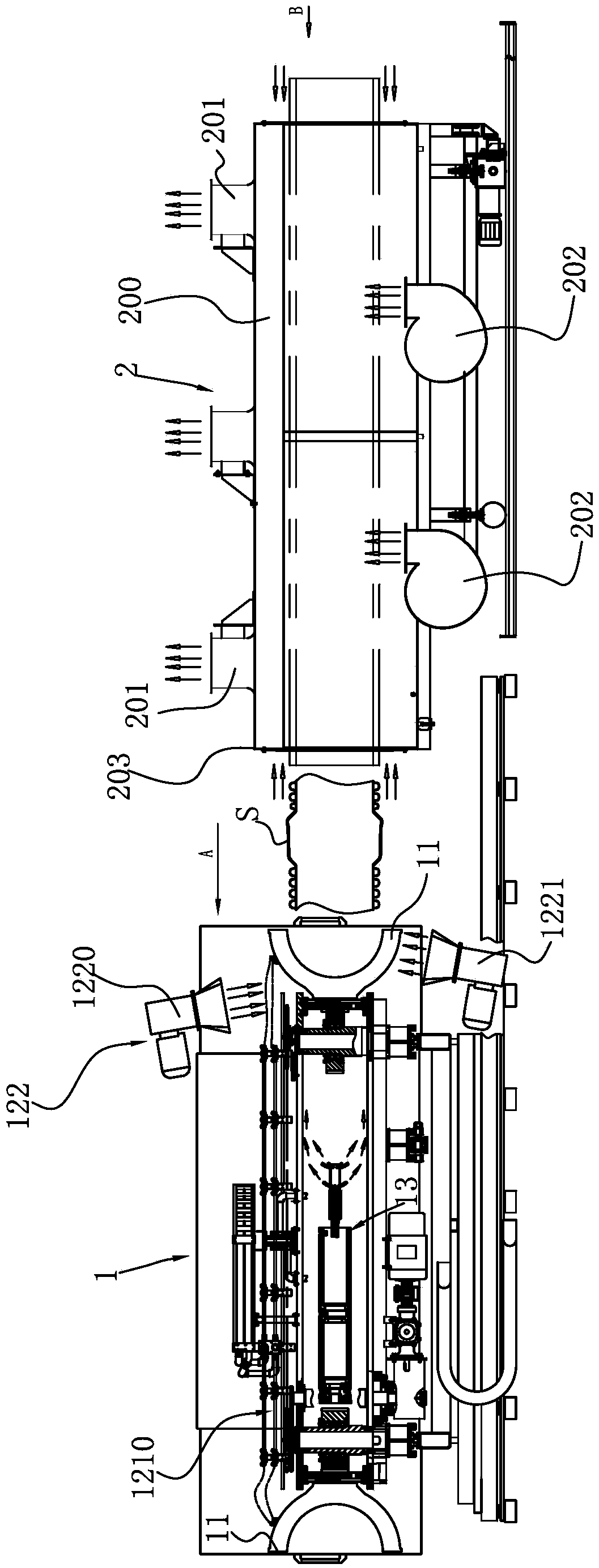

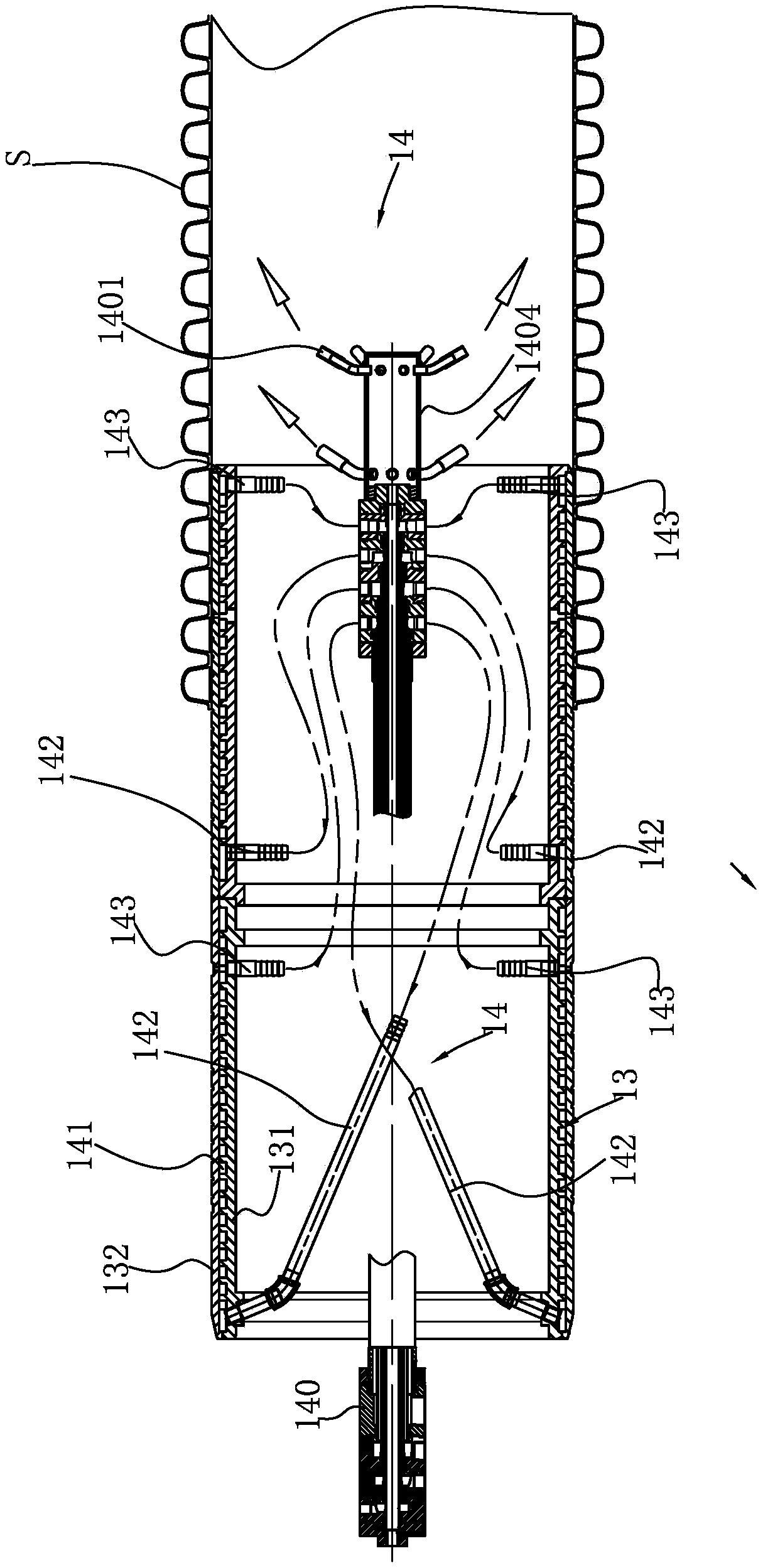

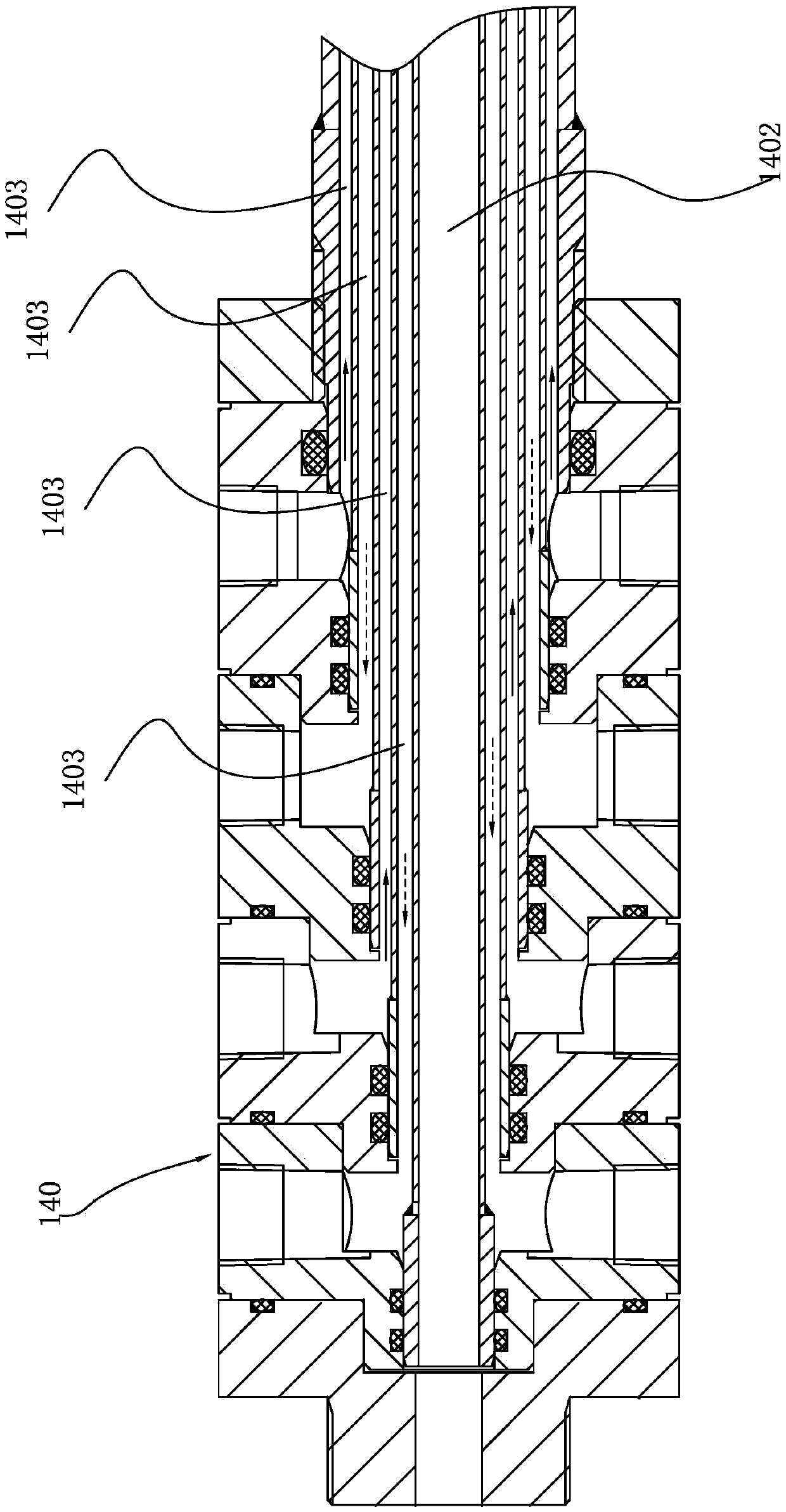

[0032] combine figure 1 A brief description of the manufacturing process of the plastic bellows: the plastic raw material is first heated and plasticized by the plastic extruder, and then transformed into a molten state. The molten plastic material passes through the extrusion head, and the extrusion head extrudes two Tube blanks with different diameters in the shape of tubes, the large-diameter tube blank is the outer wall of the tube, and the small-caliber plastic tube blank is the inner wall of the tube. After the tube blank enters the bellows forming device 1, the outer tube blank passes through compressed air and vacuum. Working t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com