Preparation method for integral glass-imitated 3D curved surface cover plate

A 3D, curved surface technology, applied in the field of preparation of integrated imitation glass 3D curved surface cover plate, can solve the problems of complex processing technology of 3D glass curved surface cover plate, the impact resistance needs to be further improved, and the glass substrate is not resistant to stretching, etc. To achieve the effect of strong plasticity, good impact resistance at high and low temperature, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

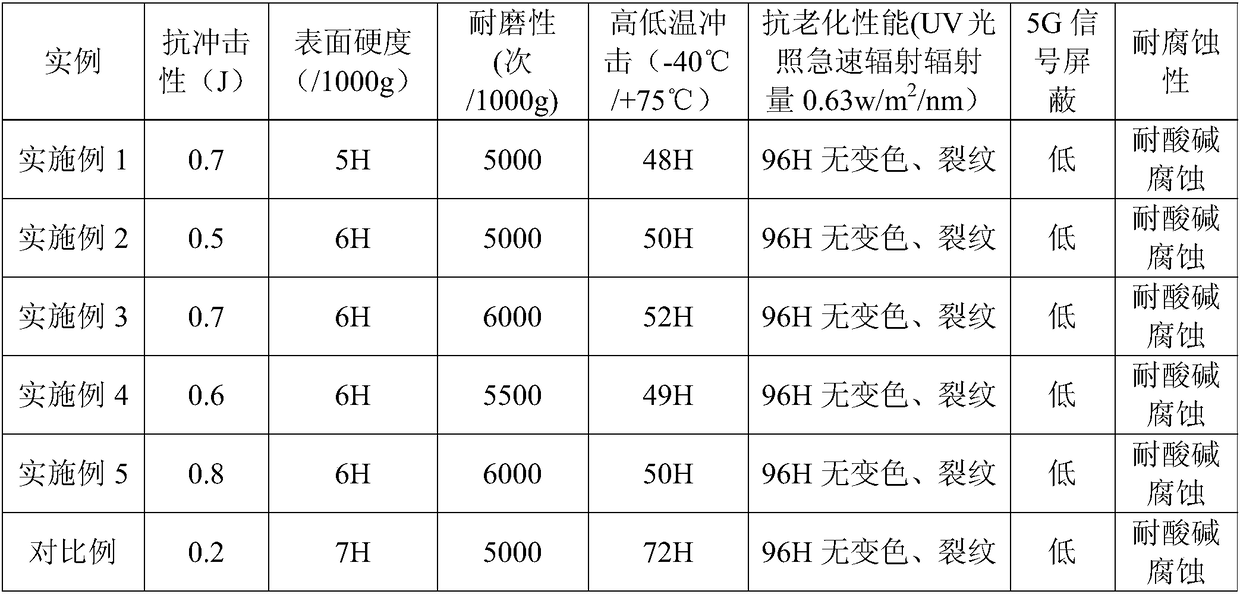

Examples

preparation example Construction

[0032] The preparation method of the integrated imitation glass 3D curved surface cover plate of the present invention, described preparation method comprises the following steps:

[0033] 1) 3D injection molding: use optical grade transparent plastic for 3D injection molding;

[0034] 2) hardening treatment: hardening the material after step 1) 3D injection molding;

[0035] 3) OPVD coating: performing OPVD coating on the material after step 2) hardening treatment;

[0036] 4) Spraying: spraying the material after step 3) OPVD coating to obtain an integrated imitation glass 3D curved surface cover plate.

[0037] Among them, the injection molding process adopts optical-grade compression molds; high-precision optical-grade injection molding machines compress injection molding. The OPVD coating process uses a vacuum evaporation machine.

Embodiment 1

[0039] The preparation method of the integrated imitation glass 3D curved surface cover plate of the present embodiment comprises the following steps:

[0040] 1) 3D injection molding: 3D injection molding is carried out by using optical-grade transparent plastic through the process of material melting → upper mold → debugging → mold clamping → injection filling → pressure holding molding → cooling → mold opening, and the melting temperature of the material is 210 ° C. The injection pressure of injection filling is 130MPa, the injection time is 2s, the pressure of pressure-holding molding is 40MPa, and the time of pressure-holding molding is 40s;

[0041] 2) Hardening treatment: harden the material after step 1) 3D injection molding with hardening solution, the main component of the hardening solution is polyurethane acrylate, and the hardening time is 10s;

[0042] 3) OPVD coating: OPVD coating is carried out on the material after step 2) through the process of rack → vacuumi...

Embodiment 2

[0046] The preparation method of the integrated imitation glass 3D curved surface cover plate of the present embodiment comprises the following steps:

[0047] 1) 3D injection molding: 3D injection molding is carried out by using optical-grade transparent plastic through the process of material melting → upper mold → debugging → mold clamping → injection filling → pressure-holding molding → cooling → mold opening. The melting temperature of the material is 220 ° C. The injection pressure of injection filling is 100MPa, the injection time is 3s, the pressure of pressure-holding molding is 50MPa, and the time of pressure-holding molding is 30s;

[0048] 2) Hardening treatment: harden the material after step 1) 3D injection molding with hardening solution, the main component of the hardening solution is polyurethane acrylate, and the hardening time is 15s;

[0049] 3) OPVD coating: OPVD coating is carried out on the material after step 2) through the process of rack → vacuuming →...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com