Combined cycloid rotor and preparation method thereof

A combined and cycloidal technology, which is applied to rotary piston/oscillating piston pump components, mechanical equipment, rotary piston pumps, etc., can solve the problems that the combined cycloidal rotor is not easy to realize, and achieve a short production cycle , high dimensional accuracy, and the effect of meeting the requirements of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0036] This patent provides a variety of parallel schemes, and the different expressions belong to the improved scheme based on the basic scheme or the parallel scheme. Each scheme has its own unique characteristics.

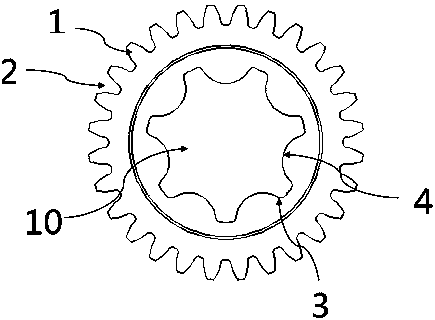

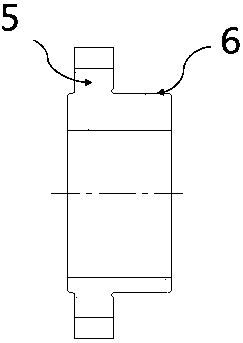

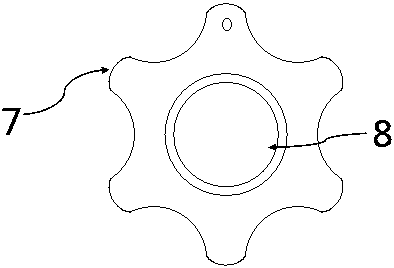

[0037] A combined cycloidal rotor, combined with figure 1 , 2 , 5, characterized in that the outer rotor includes a cylindrical outer circle 6, and there is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com