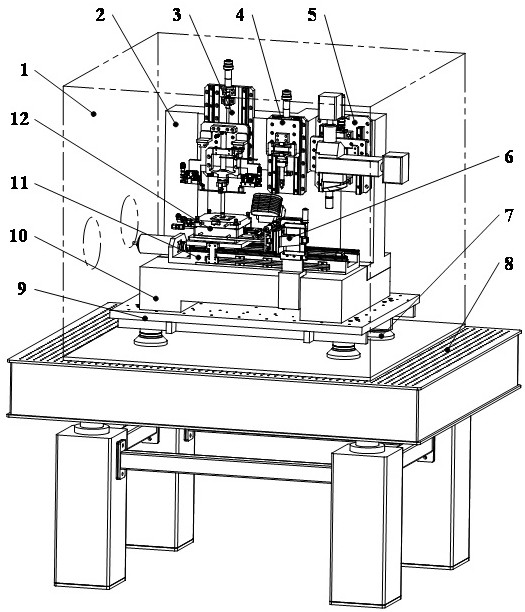

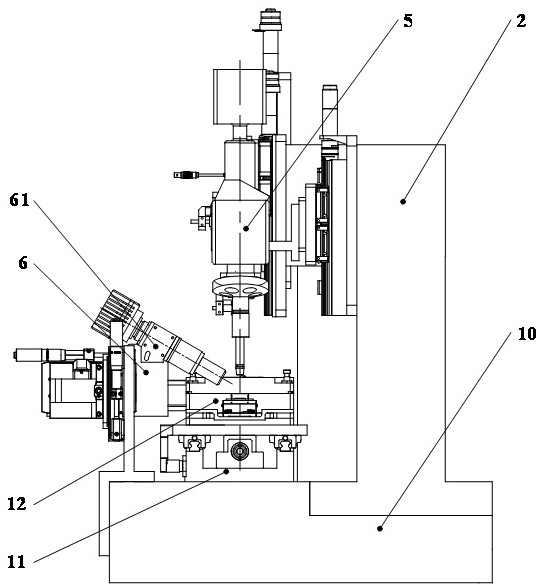

Traceable in-situ micro-nano indentation test instrument and method under variable-temperature working condition

A testing instrument, micro-nano technology, applied in the direction of using stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve the problems of inaccurate indentation depth measurement, single dimension of the test object, uneven temperature loading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

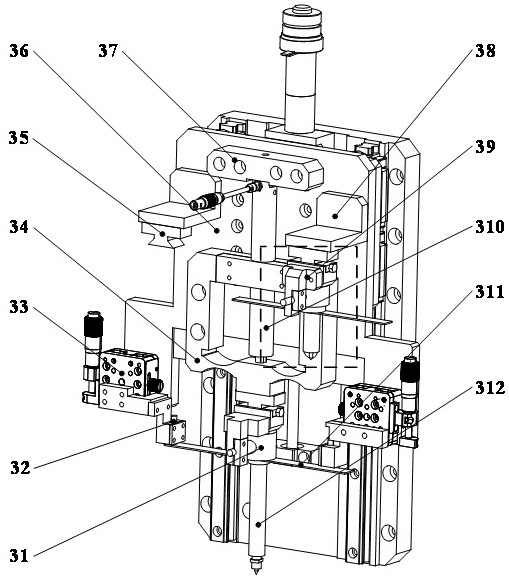

[0056] In the following, an in-situ micro-nano indentation test method under variable temperature conditions will be described in detail.

[0057] see Figure 10 As shown, it is assumed that the thickness of the test sample 122 is t, and the plane lengths are a and b respectively. If t<<a, b is satisfied, the test sample 122 is a bulk material; otherwise, the test sample 122 is a thin film material. Then determine the mechanical loading module used according to the dimensions of the test sample 122, for in-situ testing and traceability calibration of bulk / film materials (only limited to growth / coating on substrate materials) variable temperature micro-area mechanical properties with indentation testing as the core The general workflow is as follows:

[0058] First, see Figure 9 As shown, the functional pressure head 393 at the end of the macro-micro switching mechanical loading module 3 pressure rod 312 is replaced with a standard aluminum mirror, and the axis of the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com