Preparation method of hybrid synergistically reinforced iron-based wear-resistant material

A wear-resistant material, iron-based technology, used in metal material coating technology, metal processing equipment, liquid chemical plating, etc. Abrasiveness, the effect of short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing an alumina and zirconia hybrid synergistically reinforced iron-based wear-resistant material, comprising the following steps:

[0048] Step 1, Al 2 o 3 , ZrO 2 Pretreatment of ceramic particles;

[0049] Use a 3mm stainless steel sieve to screen out ceramic particles with a diameter greater than 3mm to ensure the uniformity of the particle size of the ceramic particles used; ultrasonically clean the screened ceramic particles in an alcohol solution with a volume percentage of 50% for 5 minutes , remove surface impurities and oil stains, and ensure that the interface between ceramic particles and metal substrates is clean;

[0050] Step 2, Al 2 o 3 , ZrO 2 Electroless nickel plating of ceramic particles; nickel plating steps are as follows:

[0051] a. Soak the ceramic particles in acetone for 3 minutes, then put them in 200g / L sodium hydroxide solution and 2.4mol / L hydrochloric acid solution for 20 minutes each, and perform ultrasonic clean...

Embodiment 2

[0073] Analyze and test the alumina and zirconia hybrid synergistically reinforced iron-based wear-resistant materials prepared in Example 1

[0074] ①Using the Archimedes drainage method to test the density of alumina and zirconia hybrid synergistically reinforced iron-based wear-resistant materials;

[0075] The test shows that the density of the iron-based wear-resistant material reinforced by the hybrid of alumina and zirconia is as high as 98%.

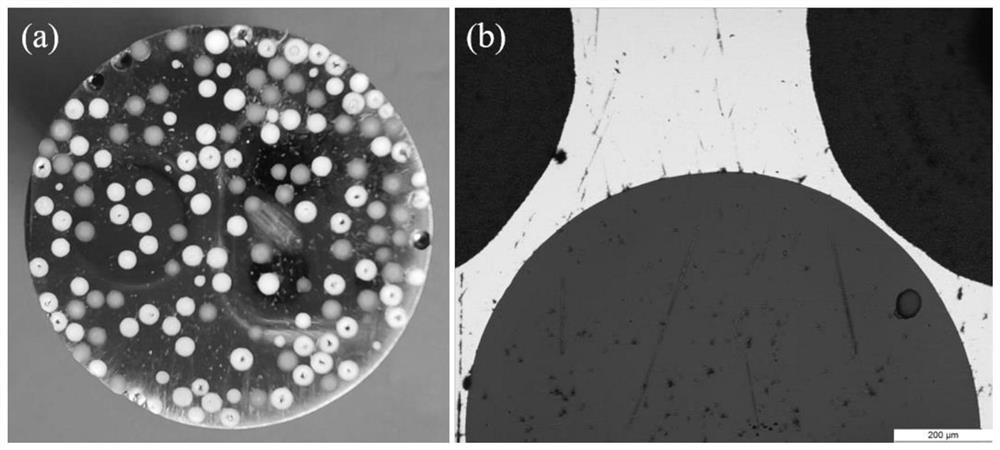

[0076] ② Use a metallographic microscope and a scanning electron microscope to observe the distribution of alumina and zirconia in the metal matrix and the interface bonding of particles / matrix; figure 2 (a) It can be seen that alumina and zirconia ceramic particles are evenly distributed inside the metal matrix, figure 2 (b) It can be seen that the interface between the ceramic particles and the metal substrate after nickel plating is clean and free of defects such as impurities;

Embodiment 3

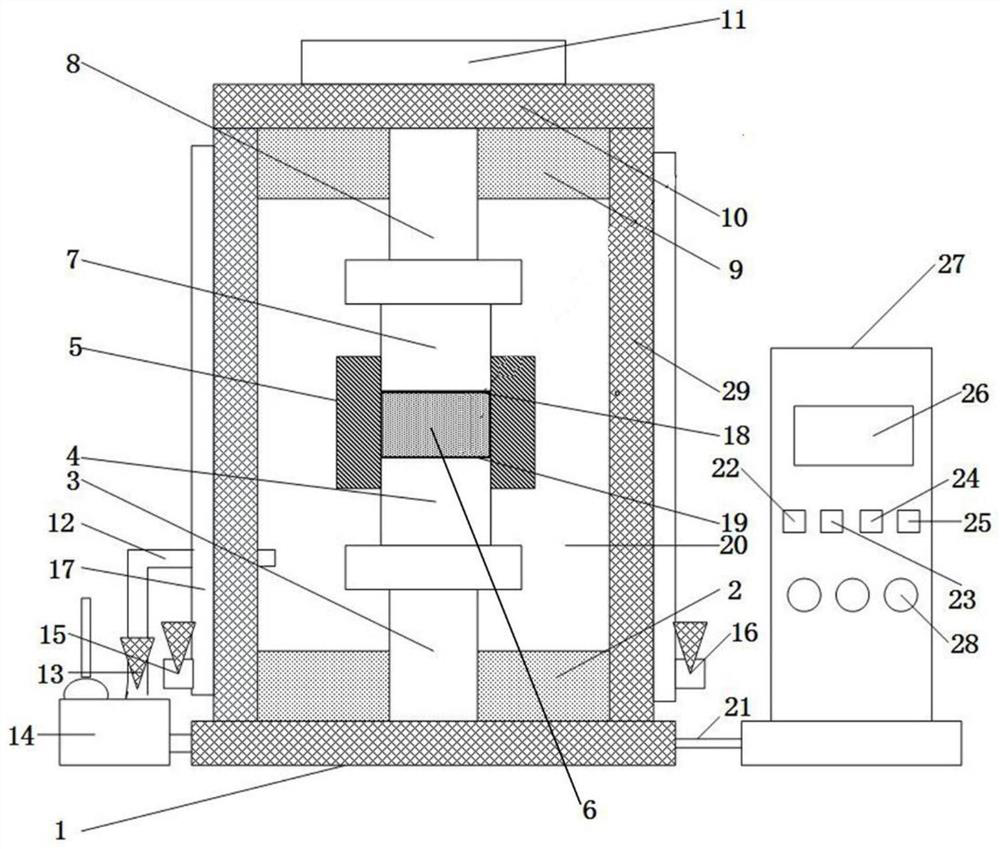

[0078] The high-frequency pulse current sintering device is vertical, including a high-frequency pulse current sintering furnace (29) and an electric control box (27) connected to each other by wires (21);

[0079]The high-frequency pulse current sintering furnace (29) comprises a top base (10), a base (1) and a vacuum chamber (20) between the top base (10) and the base (1), the top base (10 ) is connected with a pressure motor (11), the top and bottom in the vacuum furnace chamber (20) are respectively provided with an upper electrode plate (9) and a lower electrode plate (2), the middle of the upper electrode plate (9) The lower part and the middle upper part of the lower electrode plate (2) are vertically connected with an upper electrode (8) and a lower electrode (3) respectively, and the lower end of the upper electrode (8) and the upper end of the lower electrode (3) are respectively connected with an upper pad Block (7) and lower pad (4), graphite mold (5) is arranged b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com