A dryer for chemical fabric

A dryer and fabric technology, applied in dryers, drying, progressive dryers, etc., can solve the problems of high-temperature steam consumption, slow heating of the drying cylinder, and large steam consumption, so as to improve the utilization rate of heat energy. , The effect of small steam consumption and uniform surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

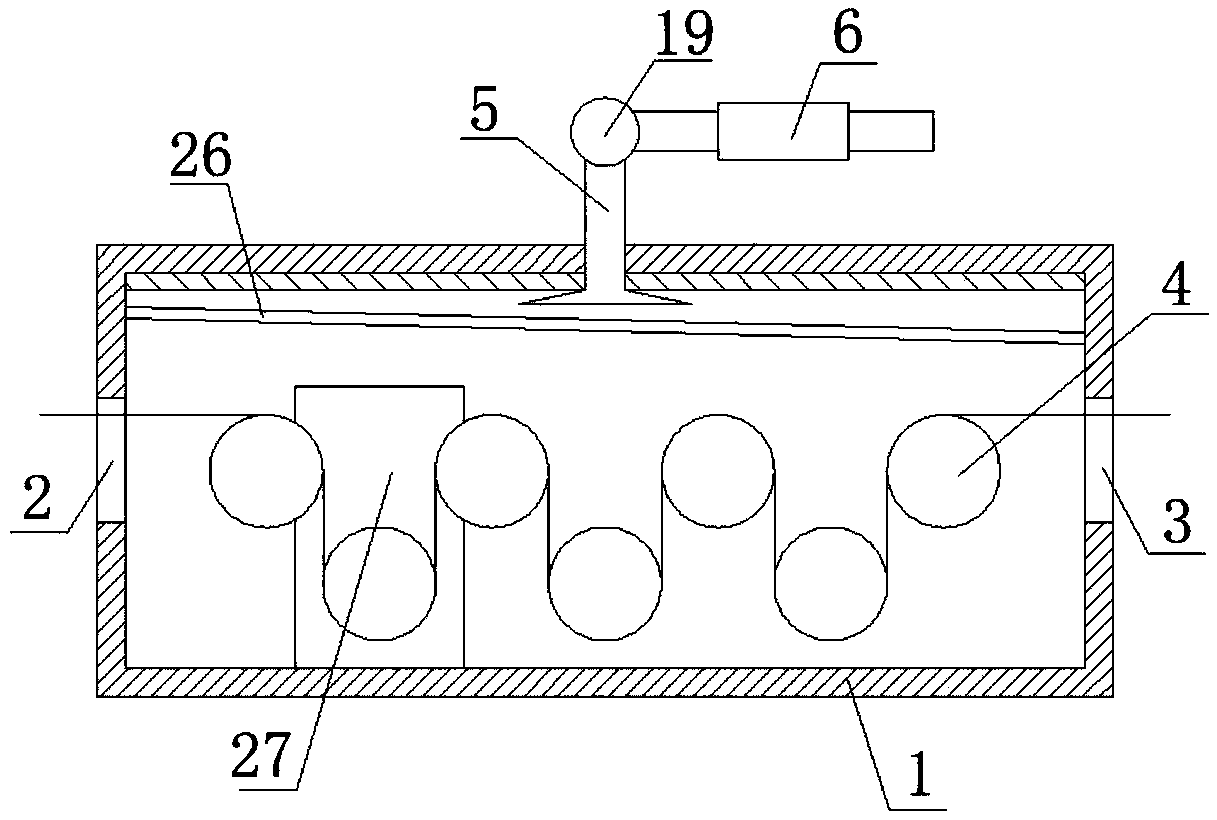

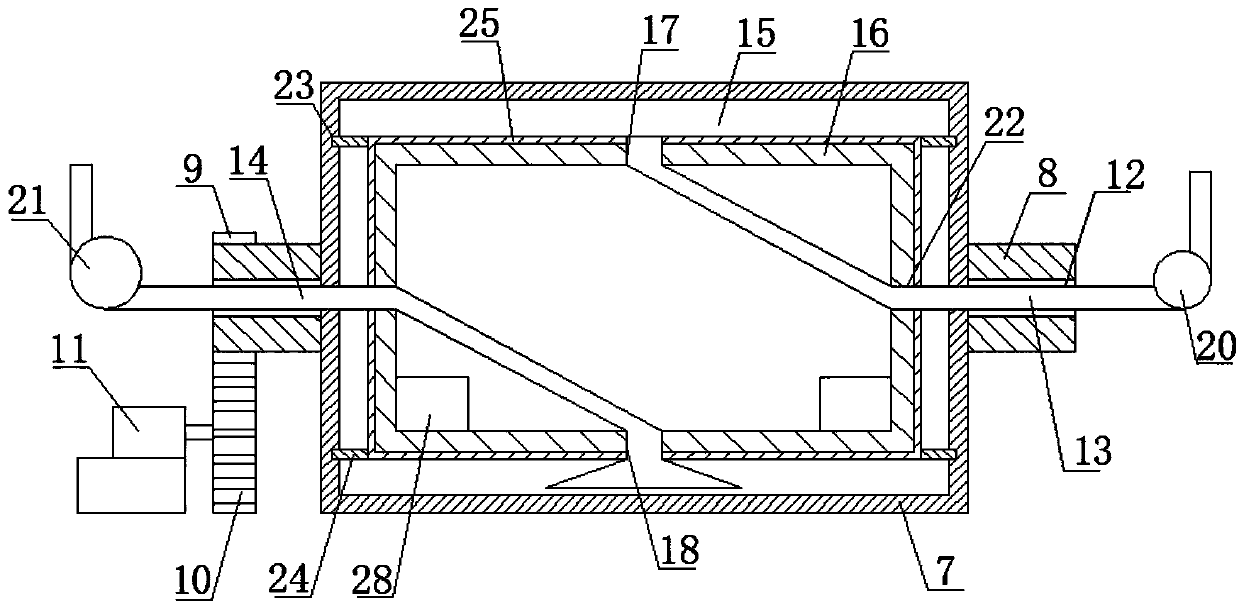

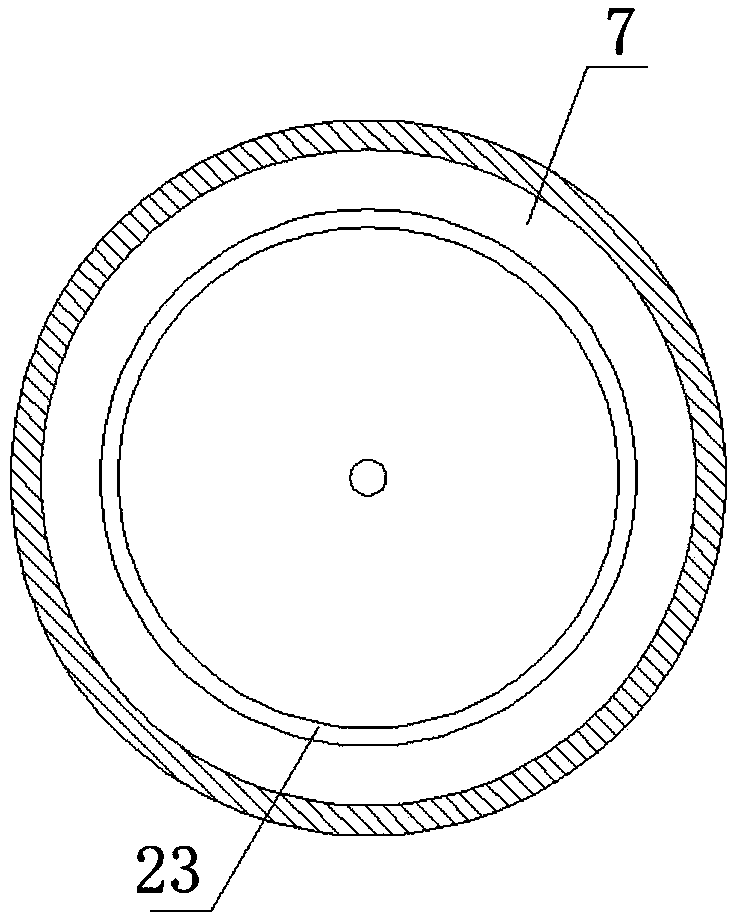

[0019] Example. A kind of chemical fiber cloth dryer, constituted as Figures 1 to 4 As shown, including an oven 1, the two ends of the oven 1 are respectively provided with a feed port 2 and a discharge port 3; the oven 1 is provided with upper and lower rows of drying cylinders 4, and the drying cylinders 4 in the upper row of drying cylinders 4 and the lower row of drying cylinders The drying cylinders 4 in the drying cylinders 4 are mutually staggered; the top of the oven 1 is connected with an exhaust pipe 5, and the exhaust pipe 5 is connected with a heat exchanger 6; Both sides are fixedly connected with a rotating shaft 8; the outside of the rotating shaft 8 on one side of the cylinder body 7 is fixedly connected with a ring gear 9, and a gear 10 is arranged below the ring gear 9; a driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com