Machines for manufacturing and/or processing fibrous webs

A fibrous web, technology of machines, applied in the field of machines for manufacturing and/or processing fibrous webs, paper or cardboard webs, machines for manufacturing and/or processing fibrous webs, capable of solving production interruptions, difficult guiding and splitting of fibrous webs, Web tearing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

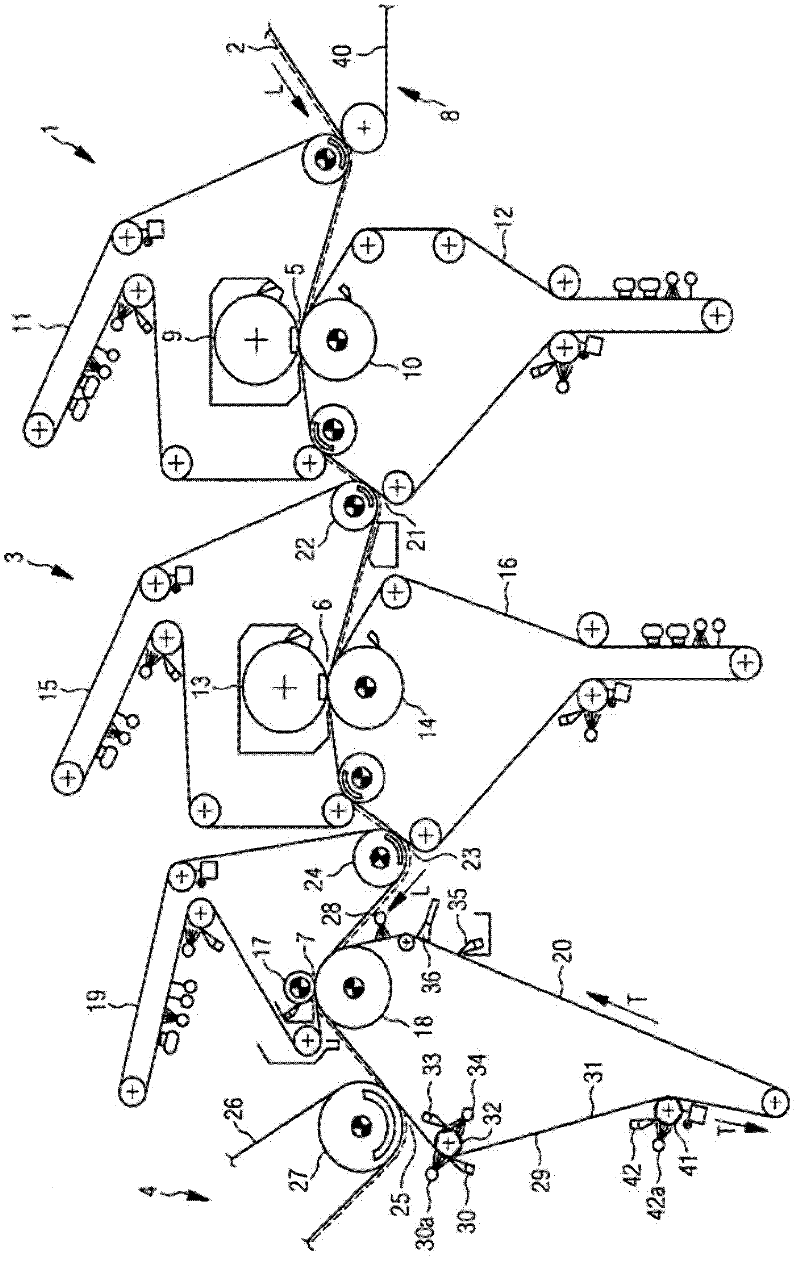

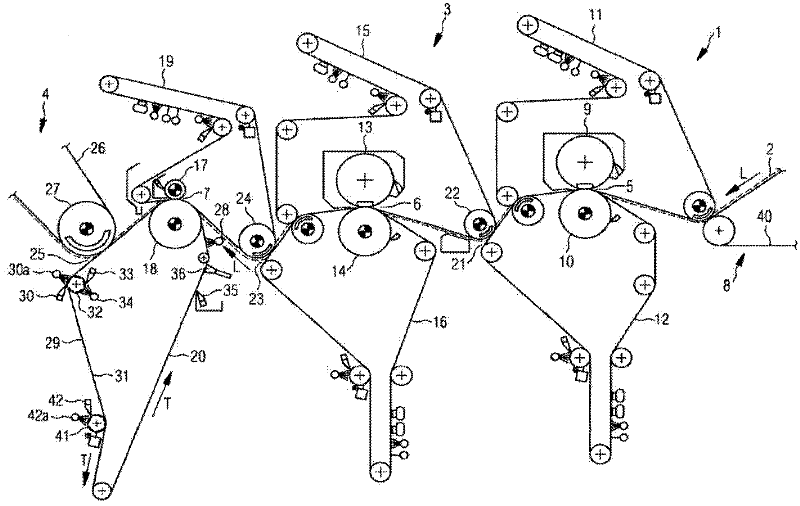

[0068] figure 1 An embodiment of a machine 1 according to the invention for producing and / or processing a fibrous web 2 is shown, which is now indicated by dashed lines.

[0069] The paper machine has a forming section 8 , a press section 3 following the forming section 8 in the web running direction L, and a drying section 4 following the press section 3 in the web running direction L. The press section 3 has three press nips 5-7, i.e. a first press nip 5, a second press nip 6 immediately after the first nip in the direction of web run and a second press nip 6 immediately behind the first nip in the direction of web run L. A third press nip 7 follows the second press nip 6 .

[0070] A first press nip 5 through which the fibrous web 2 is guided between an upper felt 11 and a lower felt 12 is formed by a shoe press roll 9 and a cylindrical counter roll 10 .

[0071] The second press nip 6 through which the fibrous web 2 is guided between an upper felt 15 and a lower felt 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com