Drying equipment for textile fabric

A textile fabric and drying equipment technology, applied in the field of textile machinery, can solve the problems of long drying time, slow drying speed, single heat source, etc., to avoid secondary infiltration, shorten drying time, and improve drying effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

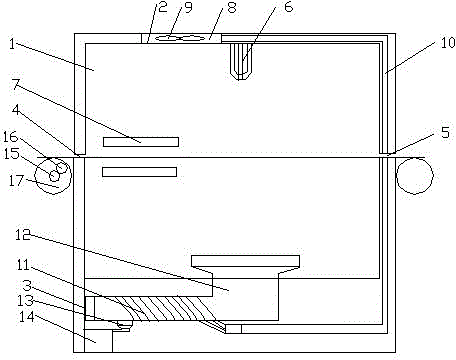

[0018] Such as figure 1 As shown, a textile fabric drying equipment of the present invention includes a drying box 1. The top and bottom of the drying box 1 are respectively provided with an air outlet 2 and an air inlet 3, the air inlet 3 and an air inlet channel 14 Connected, the opposite side walls of the drying box 1 are respectively provided with a textile fabric inlet 4 and a textile fabric outlet 5, the drying box 1 is provided with an electric heater 6, and the drying box 1 is to be dried An electric heating net 7 is arranged symmetrically above and below the textile fabric stroke, and the electric heating net 7 is parallel to the textile fabric to be dried. The top of the drying box is provided with a collection window 8, and the collection window 8 is provided with For the fan 9, the collecting window 8 is connected with a heat preservation pipe 10, and the heat preservation pipe 10 is connected with a plurality of heat-conducting copper pipes 11, and the heat-conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com