Preparation method of plant fiber porous composite material

A porous composite material and plant fiber technology, which is applied in the field of preparation of plant fiber porous composite materials, can solve problems that need to be improved, and achieve the effects of stable performance, low price, and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

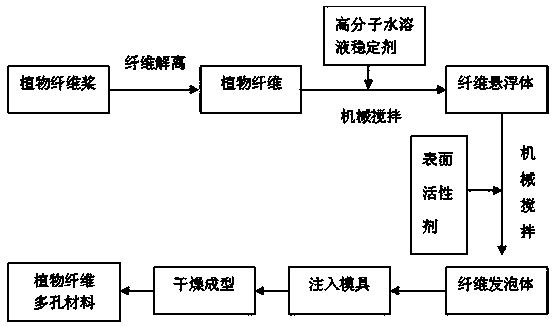

[0021] The preparation method of the plant fiber porous composite material of the present invention mainly includes the configuration and mixing of the water-soluble polymer aqueous solution stabilizer, plant fiber suspension, plant fiber foam formation and drying molding process, and its steps are as follows:

[0022] 1. Configuration of aqueous solution of water-soluble polymer stabilizer

[0023] Add the water-soluble polymer stabilizer to a certain amount of water, stir and dissolve at a certain temperature to form an aqueous solution with a mass fraction of 1%-20%.

[0024] 2. Formation of plant fiber suspension

[0025] A certain amount of plant fiber is added to the aqueous solution of the water-soluble polymer stabilizer, and mechanically stirred at room temperature to disperse the plant fiber evenly to form a plant fiber suspension.

[0026] 3. Formation of plant fiber foam

[0027] The anionic surfactant is added to the plant fiber suspension, and the high-speed me...

Embodiment 1

[0032] Stir and mix 20g of 10% polyacrylamide aqueous solution and 5g of 1% polyvinyl alcohol aqueous solution to obtain a mixed solution, add 5g of plant fibers to the mixed solution of acrylamide aqueous solution and polyvinyl alcohol aqueous solution, and use high-speed machinery Stir to disperse the plant fibers and form a plant fiber suspension, add 0.8g sodium lauryl sulfate to the plant fiber suspension, form a plant fiber foam through high-speed mechanical stirring, pour the foam into a mold and heat it at 80 o C drying and molding to obtain the plant fiber foam composite material.

Embodiment 2

[0034] Add 5g of plant fiber to 40g of polyacrylamide aqueous solution with a mass fraction of 10%, mechanically stir at room temperature at high speed to disperse the plant fiber and form a plant fiber suspension, add 0.6g of dodecylbenzenesulfonic acid to the plant fiber suspension Sodium, the plant fiber foam is formed by high-speed mechanical stirring, the foam is poured into the mold and heated at 90 o C drying and molding to obtain the plant fiber foam composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com