Special fertilizer for witloof and preparation method thereof

A special fertilizer, chicory technology, applied in the application, nitrogen fertilizer, potassium fertilizer and other directions, can solve the problems of various diseases and insect pests, the yield is not increasing, the disease resistance is poor, and the effect of reducing the number of fertilization, low cost, and improved quality is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

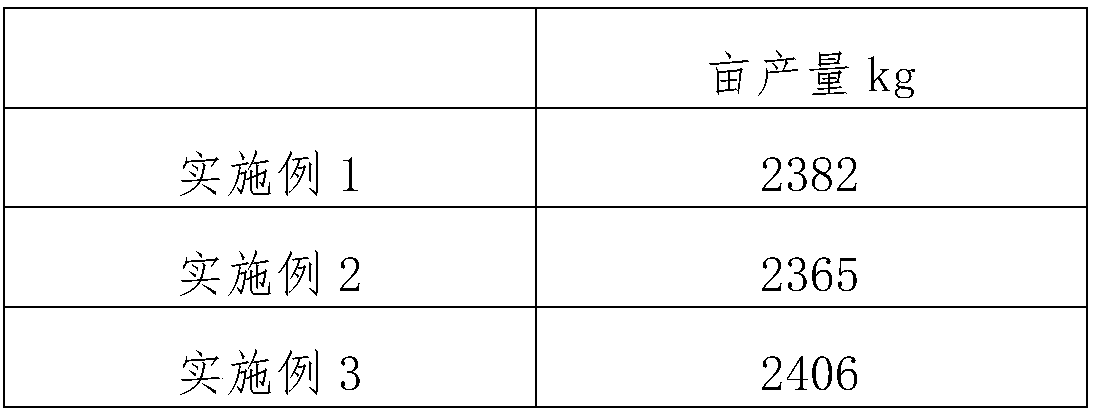

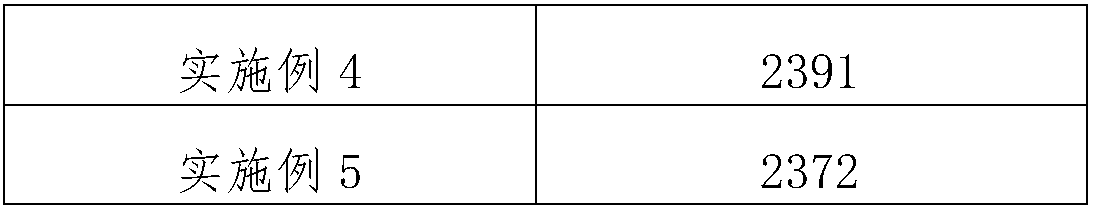

Examples

Embodiment 1

[0022] A special fertilizer for chicory, comprising the following raw materials in parts by weight: 20 kg of ammonium sulfate, 10 kg of potassium sulfate, 12 kg of potassium dihydrogen phosphate, 10 kg of calcium magnesium phosphate fertilizer, 8 kg of compound micro-fertilizer, 10 kg of chicken manure, 5 kg of sucrose residue, rapeseed cake 6kg, furfural slag 10kg, peanut shell powder 12kg, citric acid slag 8kg, compound bacteria 6kg, compound amino acid 8kg; Described compound micro-fertilizer is made up of following raw material by weight: ferrous sulfate 4kg, magnesium sulfate heptahydrate 2kg, manganese sulfate 1kg, zinc sulfate 3kg, sodium selenite 0.8kg; Described compound bacterium, is to make Bacillus subtilis, Bacillus coagulans, Bacillus lateral sporosa and Lactobacillus acidophilus by 0.8:0.2:0.6:0.3 The mass ratio is mixed; the compound amino acid is to mix arginine, glutamic acid, lysine and phenylalanine according to the mass ratio of 1:0.5:0.1:0.8.

[0023] The...

Embodiment 2

[0028] A special fertilizer for chicory, comprising the following raw materials in parts by weight: 30kg of ammonium sulfate, 20kg of potassium sulfate, 18kg of potassium dihydrogen phosphate, 20kg of calcium magnesium phosphate fertilizer, 12kg of compound micro-fertilizer, 20kg of chicken manure, 8kg of sucrose residue, rapeseed cake 12kg, furfural slag 20kg, peanut shell powder 18kg, citric acid slag 12kg, compound bacteria 8kg, compound amino acid 12kg; Described compound micro-fertilizer is made up of following raw material by weight: ferrous sulfate 6kg, magnesium sulfate heptahydrate 4kg, manganese sulfate 2kg, zinc sulfate 5kg, sodium selenite 1.2kg; Described compound bacterium is that Bacillus subtilis, Bacillus coagulans, Bacillus lateralisporus and Lactobacillus acidophilus press 1.2:0.4:0.8:0.5 The mass ratio is mixed; the compound amino acid is to mix arginine, glutamic acid, lysine and phenylalanine according to the mass ratio of 2:0.8:0.3:1.2.

[0029] The prep...

Embodiment 3

[0034] A special fertilizer for chicory, comprising the following raw materials in parts by weight: 25kg of ammonium sulfate, 15kg of potassium sulfate, 15kg of potassium dihydrogen phosphate, 15kg of calcium magnesium phosphate fertilizer, 10kg of compound micro-fertilizer, 15kg of chicken manure, 7kg of sucrose residue, rapeseed cake 10kg, furfural slag 15kg, peanut shell powder 15kg, citric acid slag 10kg, compound bacteria 7kg, compound amino acid 10kg; Described compound micro-fertilizer is made up of following raw material by weight: ferrous sulfate 5kg, magnesium sulfate heptahydrate 3kg, manganese sulfate 1.5kg, zinc sulfate 4kg, sodium selenite 1kg; described composite bacteria is to make Bacillus subtilis, Bacillus coagulans, Bacillus lateral sporosum and Lactobacillus acidophilus according to 1:0.3:0.7:0.4 The mass ratio is mixed; the compound amino acid is to mix arginine, glutamic acid, lysine and phenylalanine in a mass ratio of 1.5:0.7:0.2:1.

[0035] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com