A kind of method for preparing antimony tetrasulfide three copper nanocrystalline material

An antimony tetrasulfide and copper nanotechnology, applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc., can solve problems such as high cost and complex process, and achieve the effects of easy separation, simple preparation process, and reduced reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

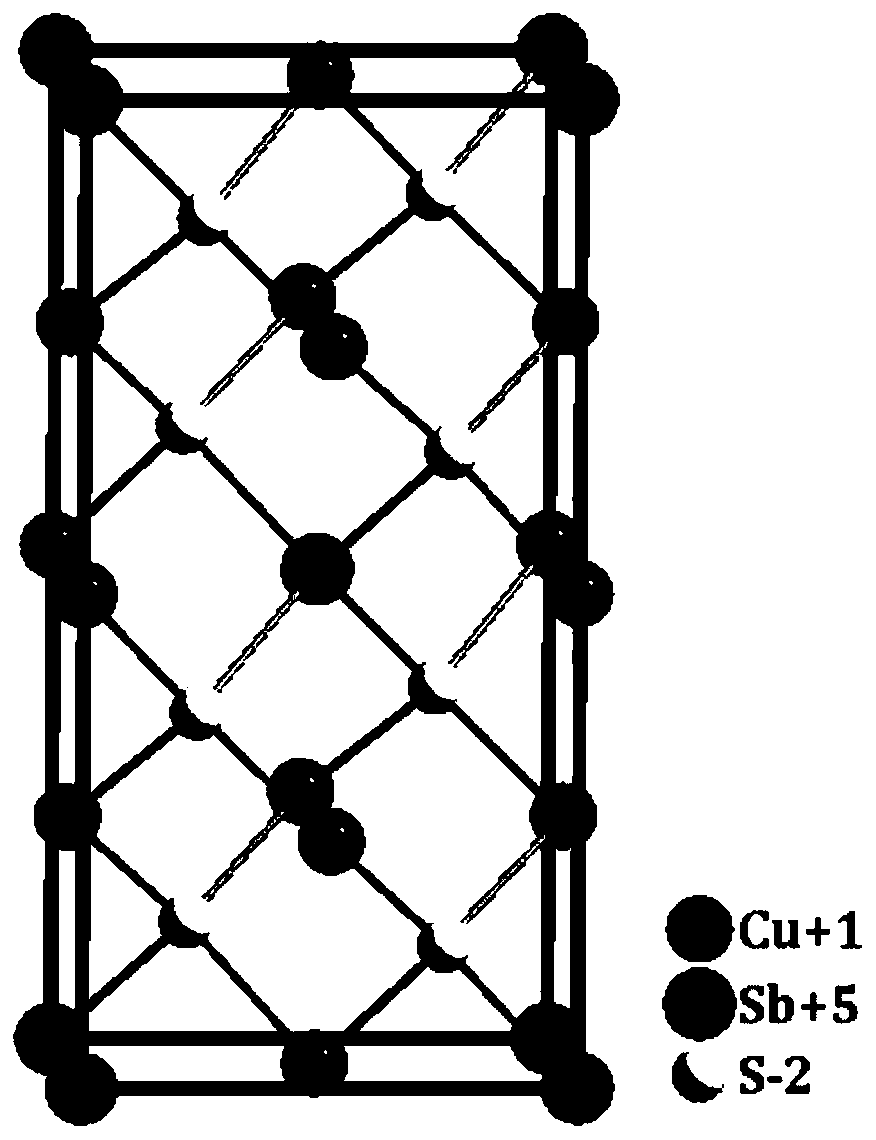

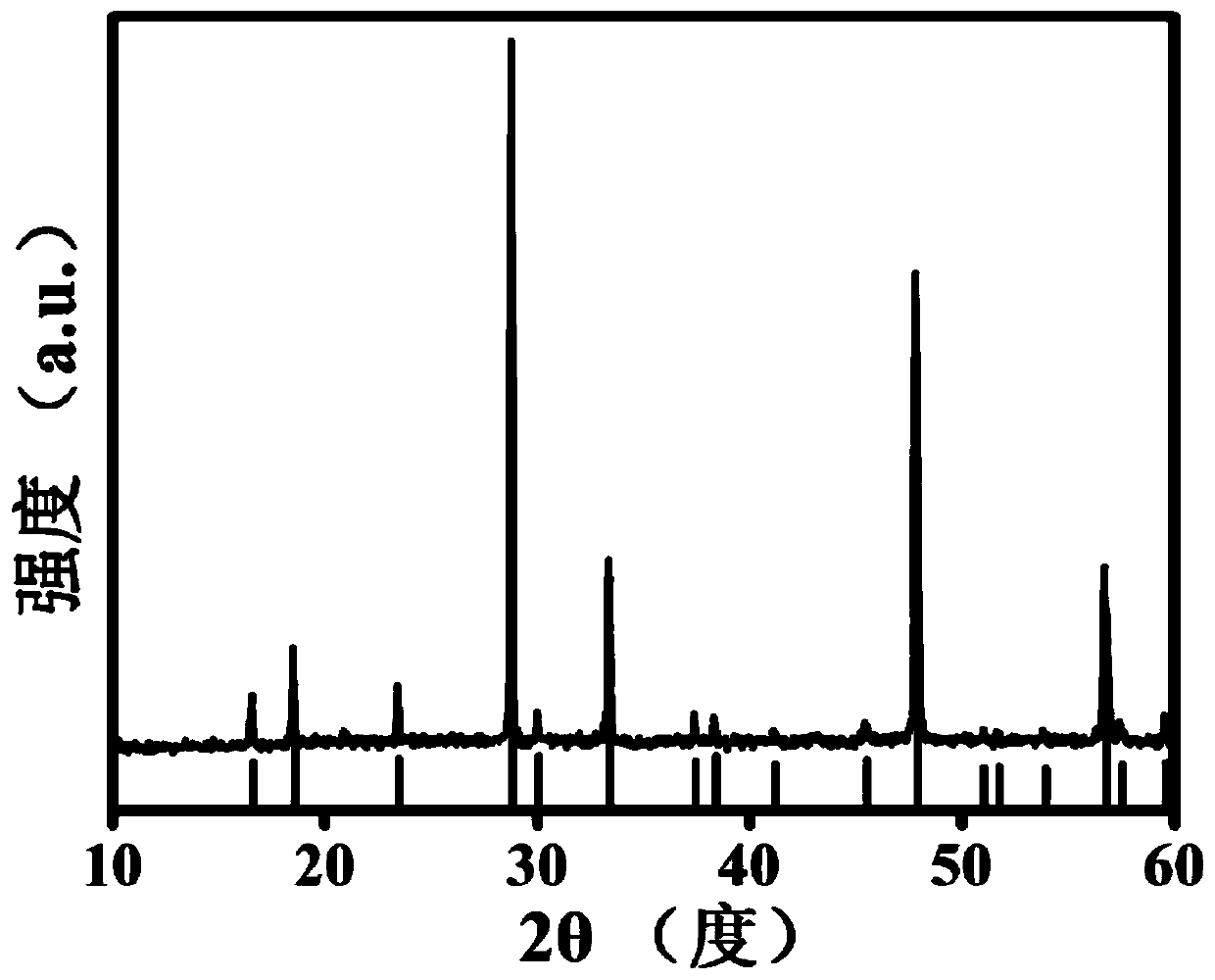

[0020] First, add the reactant precursor 6mmol antimony sulfide, 2mmol copper chloride, 10mmol sulfur powder, 10g potassium hydroxide, and 20mL deionized water into the reaction kettle in turn, stir at room temperature for 15min until the reactants are dissolved, and then seal the reaction kettle Put it in a vacuum oven at 230°C for 2 days, centrifuge and dry to obtain Cu 3 Sb 4 Semiconductor nanocrystalline materials. figure 1 Prepare sulfide Cu for a kind of concentrated alkali hydrothermal method of the present invention 3 Sb 4 Diagram of the crystal structure of the nanocrystal approach.

Embodiment 2

[0022] First, add the reactant precursor 4mmol antimony-sulfur compound, 4mmol copper acetate, 15mmol thiourea, 15g sodium hydroxide, and 25mL deionized water into the reaction kettle in turn, stir at room temperature for 20min until the reactant is dissolved, and then seal the reaction kettle Put it in a vacuum oven at 200°C for 3 days, centrifuge and dry to obtain Cu 3 Sb 4 Semiconductor nanocrystalline materials.

Embodiment 3

[0024] First, add the reactant precursor 12mmol antimony-sulfur compound, 8mmol copper oxide, 20mmol sulfur powder, 20g sodium hydroxide, and 30mL deionized water into the reactor, stir at room temperature for 30min until the reactant is dissolved, and then seal the reactor Put it in a vacuum oven at 240°C for 4 days, centrifuge and dry to obtain Cu 3 Sb 4 Semiconductor nanocrystalline materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com