Polymeric nanofiber-based aerogel material and preparation method thereof

A technology of nanofibers and polymers, which is applied in the field of polymer nanofiber-based airgel materials and its preparation, can solve the problems of single airgel raw materials, and achieve a safe and healthy preparation process, simple process flow, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

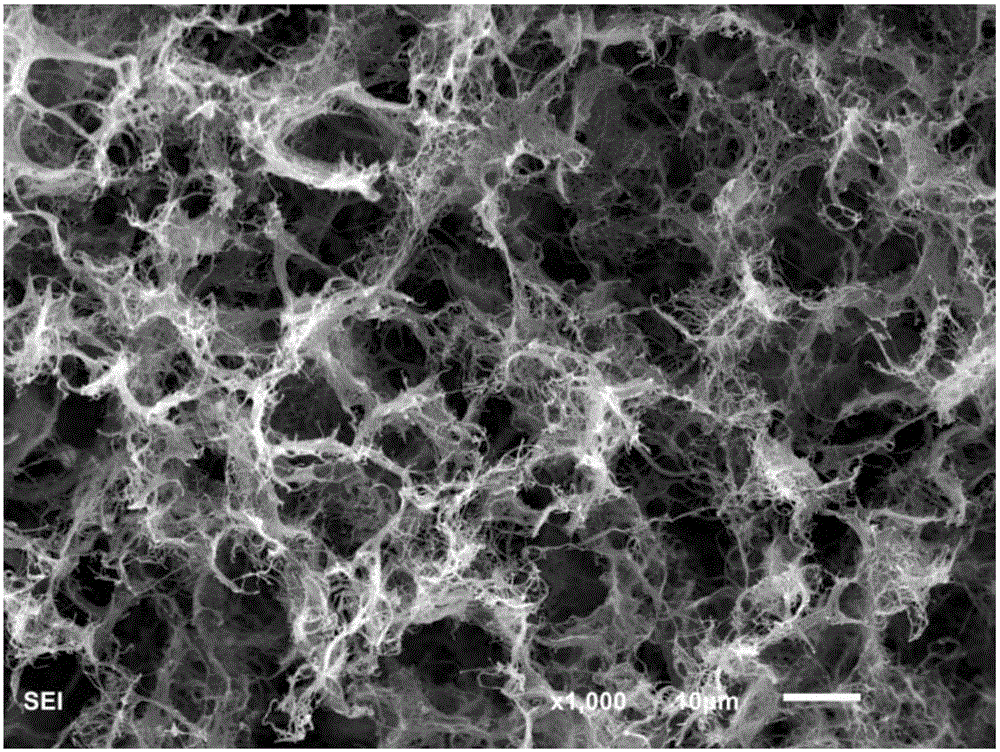

Image

Examples

preparation example Construction

[0049] A preparation method of a polymer nanofiber-based airgel material, comprising the following preparation steps:

[0050] 1) Preparation of polymer nanofibers: After mixing the thermoplastic polymer and cellulose acetate butyrate uniformly, the polymer nanofiber precursors are prepared by melt extrusion and drafting; the polymer nanofiber precursors are subjected to Acetone extraction to remove cellulose acetate butyrate to obtain polymer nanofibers;

[0051] In order to better realize the technical solution of the present invention, the thermoplastic polymer is one of polyesters, polyamides or polyolefin copolymers.

[0052] Further, the polyester is one of PET, PTT, PBT, and PBAT, the polyamide is one of PA6, PA66, PA12, and PA1010, and the polyolefin copolymer is PVA-co- One of PE, PE-co-GMA.

[0053] Wherein, the mass percentage of thermoplastic polymer and cellulose acetate butyrate is preferably 20:80.

[0054] 2) Preparation of polymer nanofiber dispersion: add ...

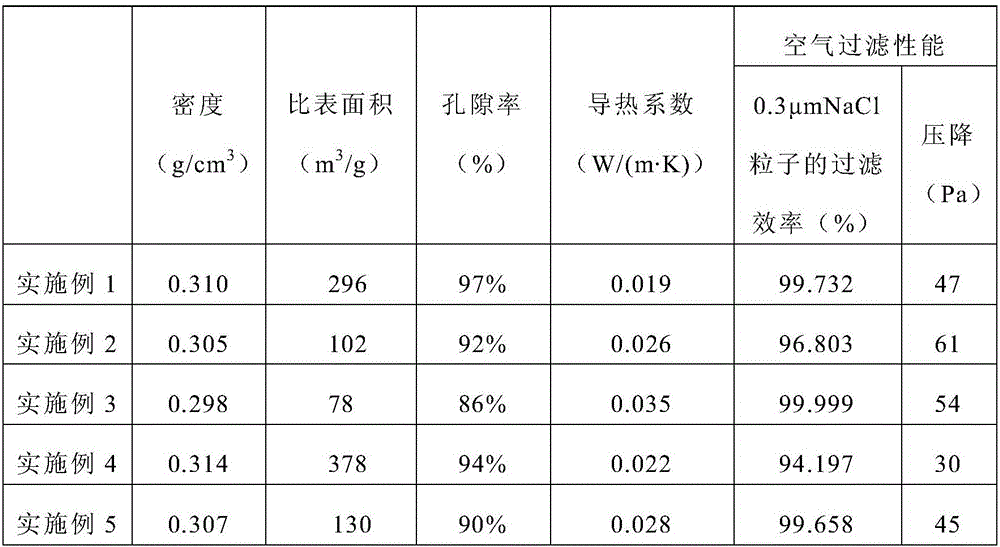

Embodiment 1

[0063] 1) Preparation of polymer nanofiber: get 20g polyester copolymer, preferably PET (also can be a kind of in PTT, PBT or Ecoflex) in the present embodiment, after mixing evenly with 80g cellulose acetate butyrate, The polymer nanofiber precursor is prepared by melt extrusion and drafting of a twin-screw extruder; and cellulose acetate butyrate is used as a matrix; the polymer nanofiber precursor is extracted with acetone to remove the cellulose acetate butyrate matrix, obtaining polymer nanofibers;

[0064] 2) Preparation of polymer nanofiber dispersion: add the polymer nanofibers prepared in step 1) to 50 g of water, and the mass percentage of polymer nanofibers and water is 1:99, and shear by an emulsifier, wherein, shear The speed is 5000r / min, and a uniformly dispersed polymer nanofiber dispersion is obtained;

[0065] 3) Preparation of polymer nanofiber-based airgel material: adding polyvinyl alcohol crosslinking agent to the polymer nanofiber dispersion prepared in...

Embodiment 2

[0067] 1) Preparation of polymer nanofibers: take 20g of polyamide copolymer, preferably PA66 in this embodiment, mix it with 80g of cellulose acetate butyrate evenly, melt extrude through a twin-screw extruder, and draw to prepare polymer nanofiber precursors; and cellulose acetate butyrate as a matrix; the polymer nanofiber precursors are extracted with acetone, and the cellulose acetate butyrate matrix is removed to obtain polymer nanofibers;

[0068] 2) Preparation of polymer nanofiber dispersion: mix 90g of ethanol with 10g of water to obtain a water-based solvent, add the polymer nanofibers prepared in step 1) into the water-based solvent, and the mass percentage of polymer nanofibers and water-based solvent is 5 : 95, sheared by an emulsifier, wherein the shear speed is 8000r / min, to obtain a uniformly dispersed polymer nanofiber dispersion;

[0069] 3) Preparation of polymer nanofiber-based airgel material: adding a polyethylene glycol crosslinking agent to the polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com