Preparation method of ceramic fiber porous combustion medium with gradient pore structure

A technology of ceramic fibers and gradient pores is applied in the field of preparation of porous ceramics, which can solve the problems of reducing combustion stability, breaking, and being easily corroded, and achieve the effects of improving combustion stability, improving service life, and avoiding acoustic shock phenomena.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

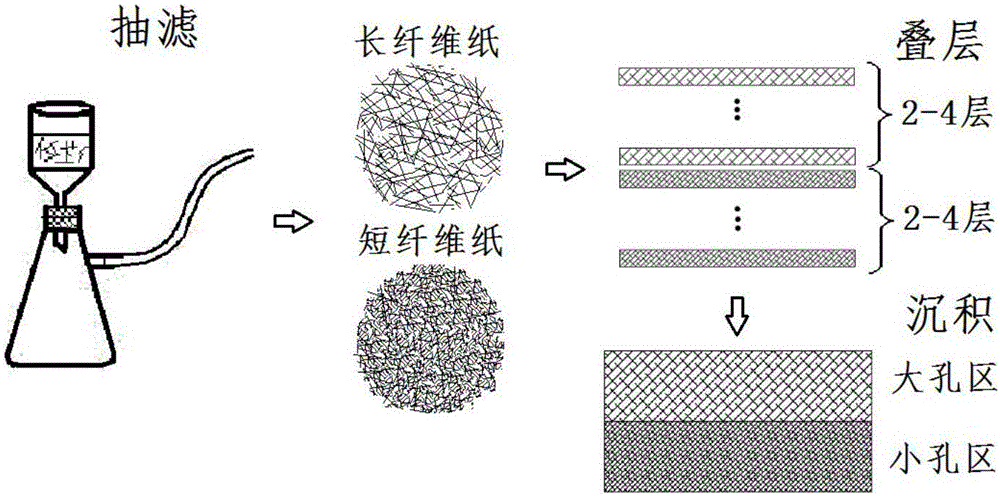

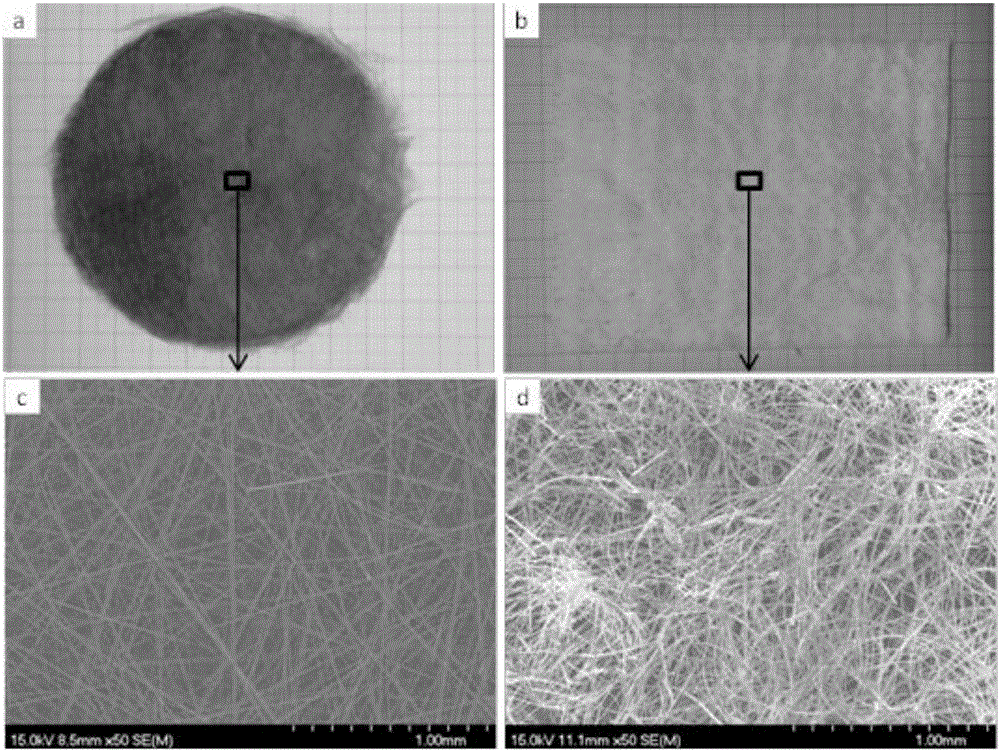

[0033] Embodiment one (single-phase fiber):

[0034] Select SiC chopped fibers with a length between 3-6mm and 10-13mm and mix them with a PVA solution with a concentration of 0.2% at a ratio of 0.4g:400mL, and mix evenly by stripping and stirring to obtain a uniform, short-term stable SiC chopped fiber suspension. The obtained SiC chopped fiber suspension is vacuum filtered to obtain a single layer of SiC chopped fiber paper with a certain pore structure and different fiber lengths. Then, the obtained single-layer SiC chopped fiber paper with different fiber lengths is laminated. The upper 3 layers are laminated with long fibers to obtain a large pore structure, and the lower 3 layers are laminated with short fibers to obtain a small pore structure, thereby obtaining a gradient pore structure. Structured SiC porous fiber mat. A certain pressure is applied to obtain a fiber mat with a thickness of about 3 mm, and then sprayed with a sizing glue for curing to obtain a SiC fib...

Embodiment 2

[0035] Embodiment two (multiphase fiber):

[0036] Choose mullite chopped fibers with a length of 3-6mm and SiC chopped fibers with a length of 10-13mm to mix with a CMC solution with a concentration of 0.2% in a ratio of 0.4g:400mL, and mix evenly by stripping and stirring to obtain Homogeneous, short-term stable mullite chopped fiber and SiC chopped fiber suspensions. The prepared mullite chopped fiber and SiC chopped fiber suspensions are vacuum filtered to obtain a single-layer mullite chopped fiber paper and SiC chopped fiber paper with a certain pore structure. The obtained single-layer mullite chopped fiber paper and SiC chopped fiber paper are laminated, the upper 3 layers are the macroporous structure obtained by laminating SiC fiber paper, and the lower 3 layers are obtained by laminating mullite fiber paper The small pore structure is used to obtain the mullite fiber-SiC fiber gradient porous mat, a certain pressure is applied to obtain a fiber mat with a thickness...

Embodiment 3

[0037] Embodiment three (multiphase fiber):

[0038] Choose Al with a length of 3-6mm and a diameter of 3-5μm 2 o 3 Chopped fibers and SiC chopped fibers with a diameter of 7-14 μm were mixed with 0.2% CMC solution at a ratio of 0.4g:400mL, and mixed evenly by stripping and stirring to obtain uniform, short-term stable Al 2 o 3 Chopped Fiber and SiC Chopped Fiber Suspension. Al obtained by vacuum filtration 2 o 3 Chopped fiber and SiC chopped fiber suspension to obtain a single layer of Al with a certain pore structure 2 o 3 Chopped fiber paper and SiC chopped fiber paper. The resulting monolayer Al 2 o 3 Chopped fiber paper and SiC chopped fiber paper are laminated, the upper 3 layers are the macroporous structure obtained by laminating SiC fiber paper, and the lower 3 layers are Al 2 o 3 The small pore structure obtained by lamination of fiber paper, resulting in Al 2 o 3 - SiC fiber gradient porous mat, apply a certain pressure to obtain a fiber mat with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com