Production method of meta-position aramid paper fibrid

A technology of aramid fibrids and production methods, which is applied in fiber raw material processing, synthetic cellulose/non-cellulose material pulp/paper, papermaking, etc., can solve the problems such as great influence on the performance of fibrids, and solve the problem of corrosion Difficult and environmental pollution problems, stable process conditions, and uniform fineness and length standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

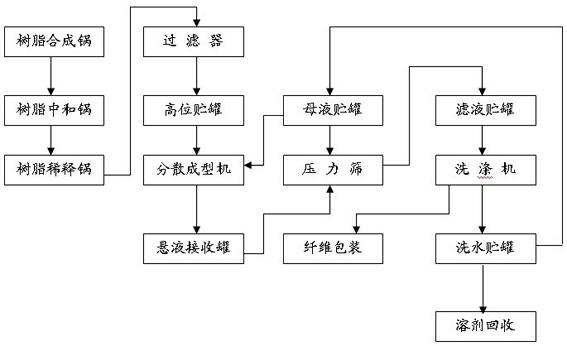

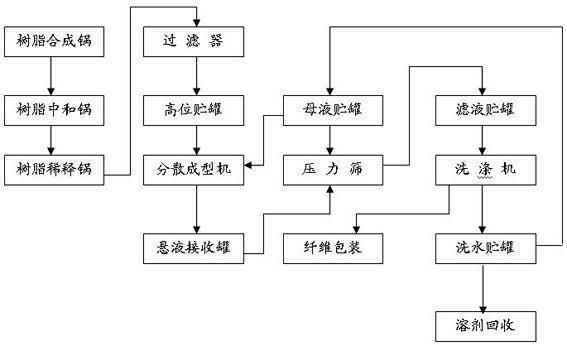

Method used

Image

Examples

Embodiment

[0034] 1. Under the condition of nitrogen protection, quantitatively add 235kg DMAC into the 300L glass-lined reaction pot, add accurately measured solid m-phenylenediamine 34.2kg under stirring, raise the temperature slightly, and keep warm and dissolve at 50~60℃ for 0.5h. Continue to pass nitrogen, cool the jacket with ice-salt water, and reduce the system temperature to 0-5°C in about 1-1.5 hours.

[0035] 2. Add 64.2~64.5kg of IPC (isophthaloyl chloride) dropwise into the pot under pressure with nitrogen, control the dropping flow rate at 0.8~1.2kg / min, and the temperature ≤ 65°C. After the addition was complete, the reaction was stirred for 1 h under the condition of continuing nitrogen flow and cooling.

[0036] 3. Stop the nitrogen flow, put the resin into the neutralization pot under stirring, add 240kg of DMAC to stir and clean the reaction pot, put it into the neutralization pot together, and slowly add the cleaning solution to the neutralization pot over 2 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com