Method for recovering multiple metals through driving microbial electrolysis cells by microbial fuel cells

A microbial electrolysis cell and fuel cell technology, which is applied in the improvement of process efficiency, photography process, instruments, etc., can solve the problem of inability to fully recover heavy metals from electroplating wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

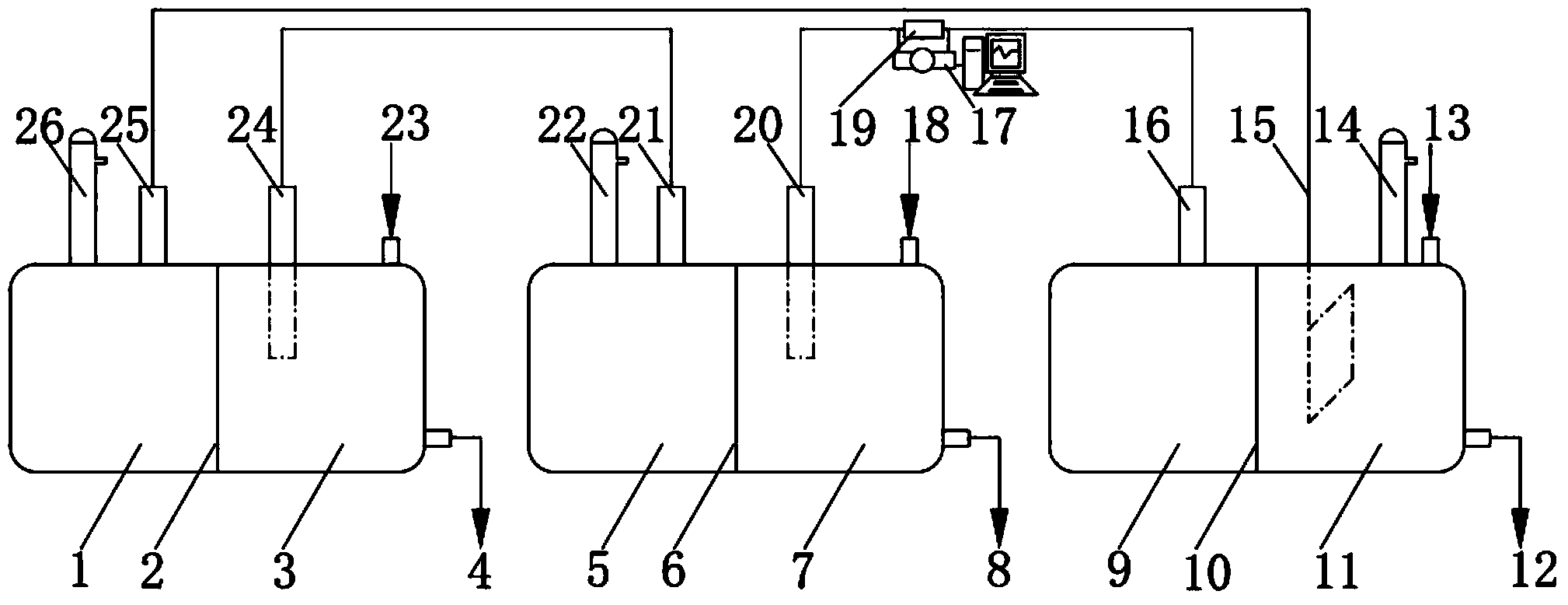

[0022] Step 1: Building MFCs Cr 、MFCs Cu and MECs Cd ,Such as figure 1 Shown: MFCs Cr Anode chamber, MFCs Cu Anode chamber, MECs Cd Anode chamber, MFCsCr cathode chamber, MFCs Cu Cathode chamber, MECs Cd The cathode chamber is made of plexiglass, MFCs Cr 、MFCs Cu and MECs Cd The volume of the solution in the anode compartment is 15mL, and the MFCs Cr 、MFCs Cu and MECs Cd The volume of the cathode chamber solution is 13mL, separated by ion exchange membrane (CMI-7000), MFCs Cr 、MFCs Cu and MECs Cd A small 10Ω resistor is connected in series to collect and calculate the current in the circuit.

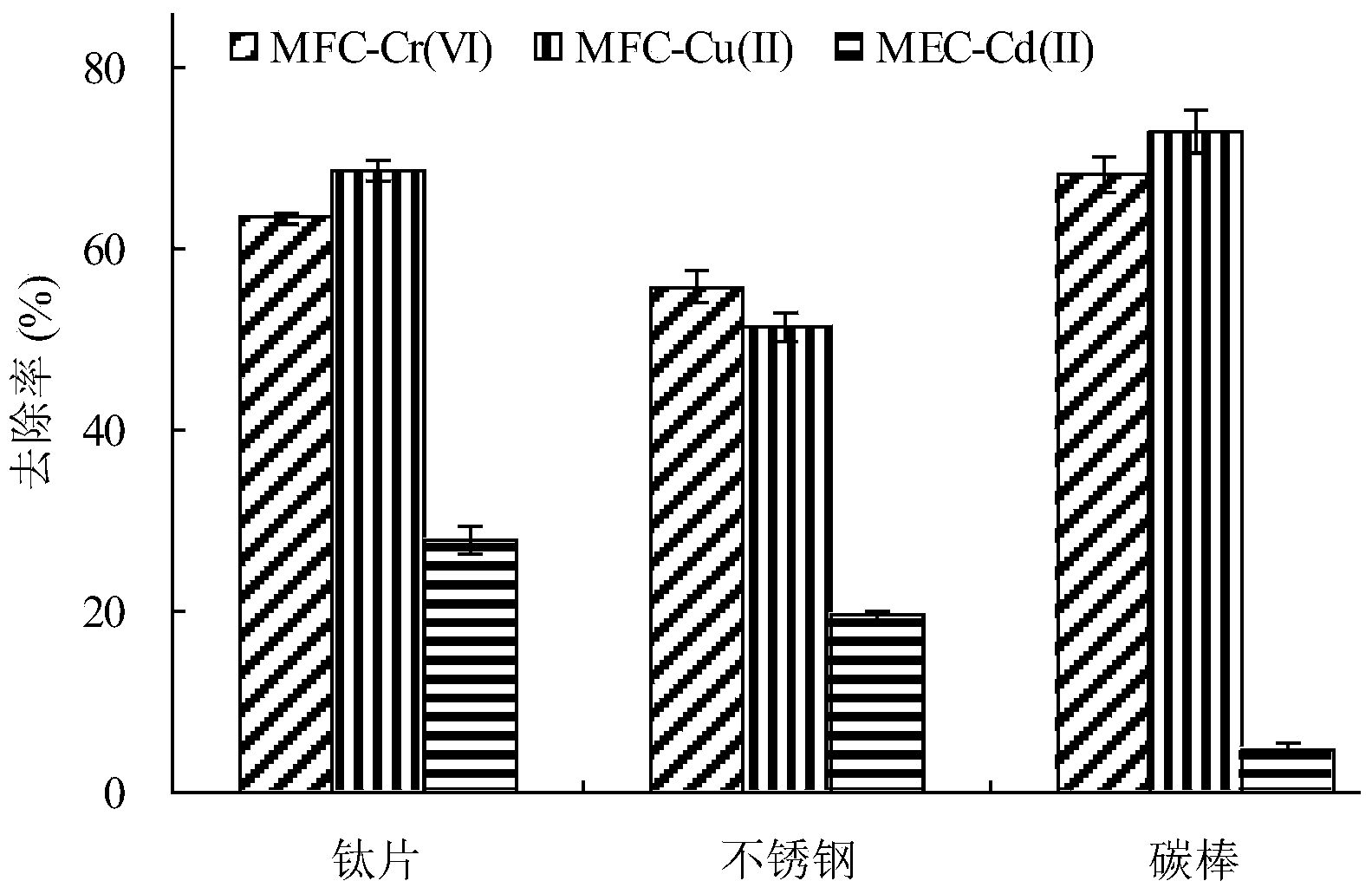

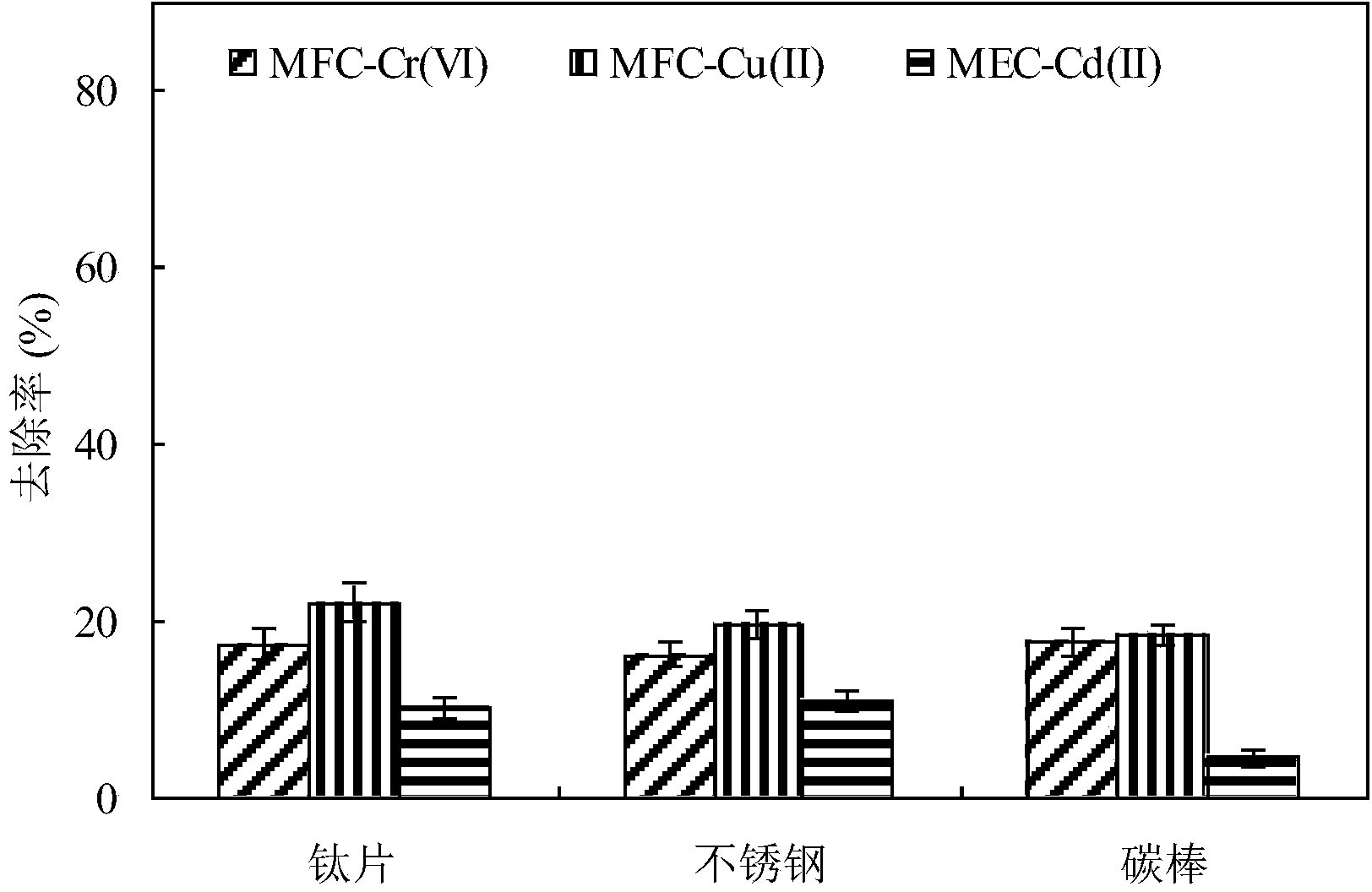

[0023] Step 2: separate the MFCs Cr and MFCs Cu Anode electrodes (carbon rods or carbon felts) and cathode electrodes (carbon rods) are placed in MFCs Cr and MFCs Cu In the anode and cathode compartments, the MECs Cd Anode electrodes (carbon rods or carbon felts) and cathode electrodes (stainless steel mesh or titanium sheets or carbon rods) are placed in MECs Cd in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com