Preparation method of electro-Fenton cathode material based on carbon felt-supported iron nanoparticles and application of electro-Fenton cathode material in degradation of organic pollutants in water

A cathode material, iron nanotechnology, applied in the direction of water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, difficult to widely use, single, etc., to ensure continuous degradation, large specific surface area, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

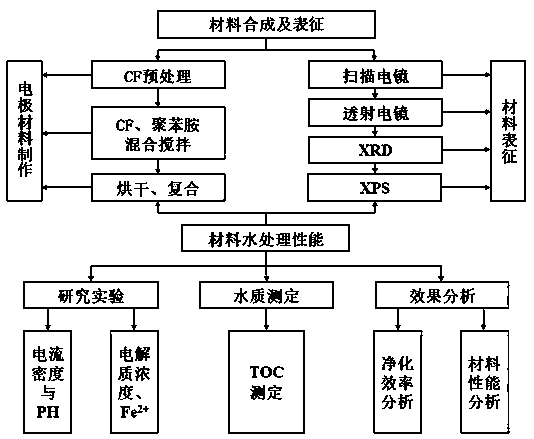

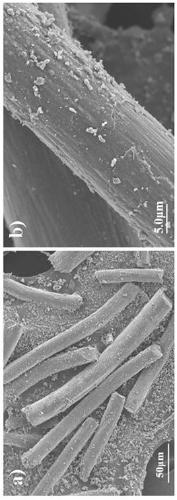

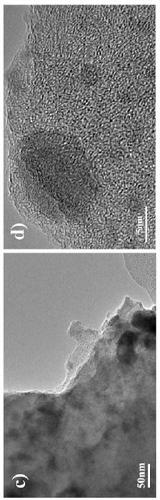

[0027] Preparation of Electro-Fenton Cathode Materials Based on Carbon Felt Supported Iron Nanoparticles:

[0028] (1) Pretreatment: select carbon fiber materials with a specification of 3cm*9cm*0.5cm, soak them in deionized water and ethanol for 30 minutes, and then wash and dry them for later use;

[0029] (2) Preparation of aniline hydrochloride solution and ferrous sulfate solution: aniline hydrochloride solution is mixed and prepared by aniline, concentrated hydrochloric acid and deionized water, and its mass ratio is 9:16:75, then carry out magnetic stirring for 30min; ferrous sulfate The solution is prepared from heptahydrate, ferrous sulfate and deionized water, and the molar concentration is 0.1mol / L;

[0030] (3) An electrodeposition device is set, and electrodes in the electrodeposition device include an anode, a cathode and a reference electrode, wherein the anode is connected to the positive pole of the electrochemical workstation, and the cathode is connected to ...

Embodiment 2

[0037] Embodiment 1 makes the removal effect of the electric Fenton cathode material based on carbon felt loaded iron nanoparticles to different dye liquors:

[0038] Reaction solution volume: 100mL;

[0039] Reaction solution temperature: 25±10°C;

[0040] The initial pH value of the reaction solution: 3;

[0041] Electrode area: 27cm 2 ;

[0042] Electrolyte concentration: 40mM Na 2 SO 4 solution;

[0043] Oxygen flow rate: 100mL / min;

[0044] Current intensity: 100mA;

[0045] Reaction time: 60min;

[0046] Different dye solutions: methyl orange, Congo red, rhodamine B;

[0047] Dye solution concentration: 100mg / L.

[0048] Table 1 Electro-Fenton cathode material is used as the cathode to the removal rate of different dye solutions

[0049]

[0050]

[0051] It can be seen from Example 2 that the electro-Fenton cathode material based on carbon felt-loaded iron nanoparticles prepared in Example 1 is particularly remarkable in the degradation efficiency of di...

Embodiment 3

[0053] Embodiment 1 makes the effect on methyl orange removal effect under different pH conditions based on the electric Fenton cathode material of carbon felt-loaded iron nanoparticles:

[0054] Reaction solution volume: 100mL;

[0055] Reaction solution temperature: 25±10°C;

[0056] Electrode area: 27cm 2 ;

[0057] Electrolyte concentration: 40mM Na 2 SO 4 solution;

[0058] Oxygen flow rate: 100mL / min;

[0059] Current intensity: 100mA;

[0060] Reaction time: 120min;

[0061] Dye solution concentration: 100mg / L methyl orange solution;

[0062] The initial pH value of the reaction solution: 2, 3, 4, 5.

[0063] Table 2 The effect of electro-Fenton cathode materials on the removal rate of methyl orange under different pH conditions

[0064] pH

2

3

4

5

Removal rate

97.8%

96.7%

91.3%

92.1%

[0065] As can be seen from Example 3, under acidic conditions, the electro-Fenton cathode material based on carbon felt-loaded iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Current intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com