Floating-bed plant coupling sediment microbiological fuel cell water purification method

A fuel cell and water purification technology, applied in biochemical fuel cells, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of many influencing factors, lack of continuity and stability, low power generation efficiency, etc., to achieve The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

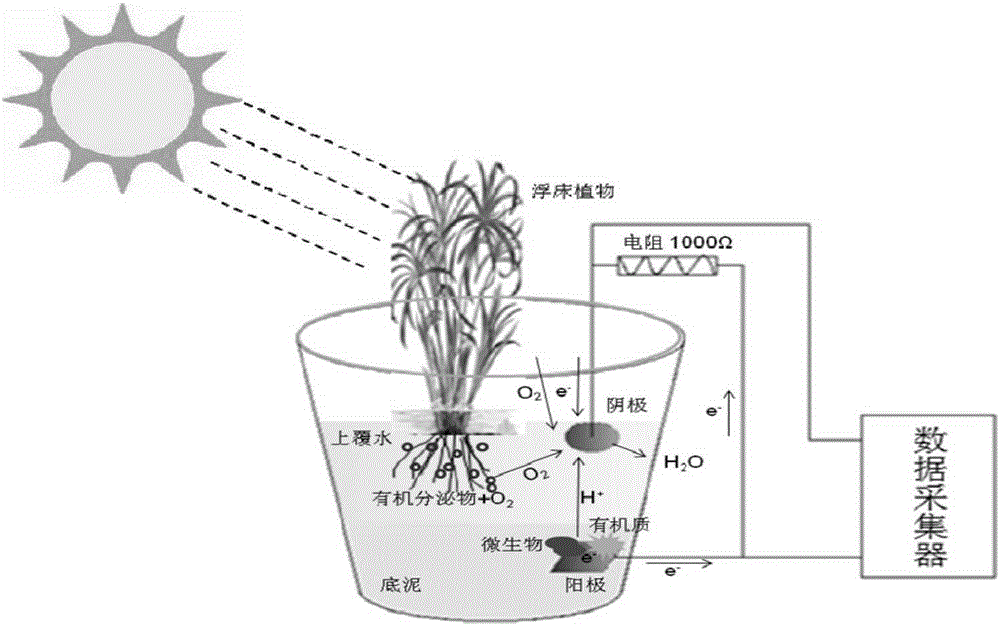

Method used

Image

Examples

Embodiment 1

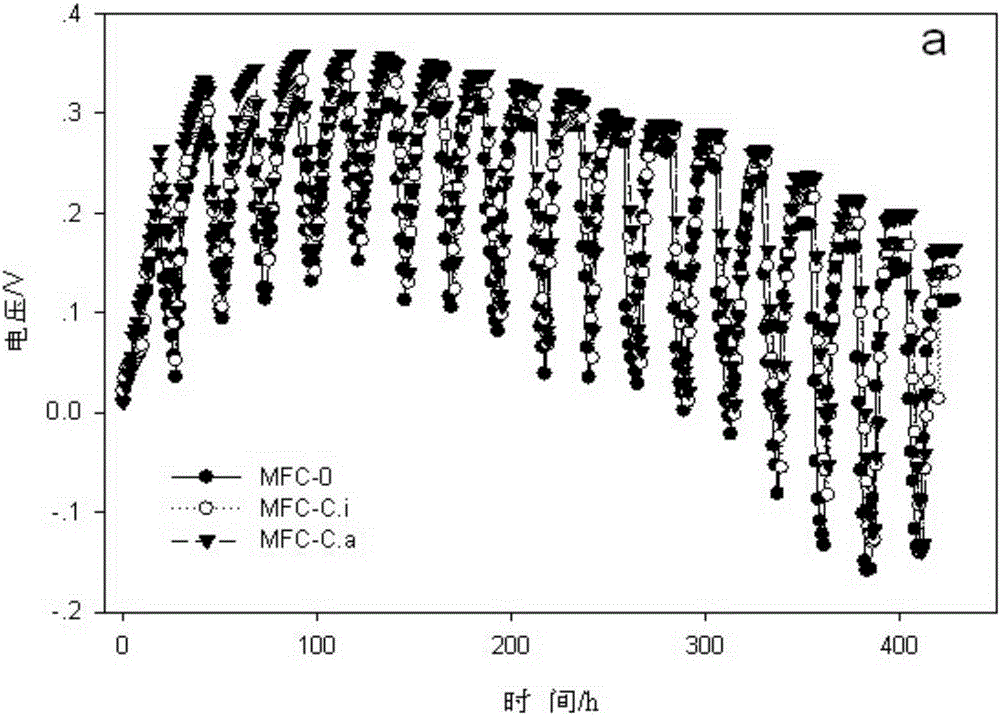

[0039] The electricity generation performance of embodiment 1P-SMFC

[0040] Three types of plant-sediment microbial fuel cells (MFC-C.a), canna-sediment microbial fuel cell (MFC-C.i), and sediment microbial fuel cell (MFC-0) were constructed respectively. Purification system, after the system is successfully started, continue to add artificial wastewater to maintain power production. The voltage value can be regarded as a complete cycle after going through three stages of rising, steady and falling until it drops below 50mV. as follows figure 2 It is the change of voltage with time in one cycle and 24 hours after the three types of systems are successfully started. It can be seen from the figure that MFC-0, MFC-C.i and MFC-C.a can all present three stages of rising, stable and falling in a general trend within a power generation cycle, and the power generation performance of MFC-C.a is slightly higher than that of MFC-C.i and MFC-0.

Embodiment 2

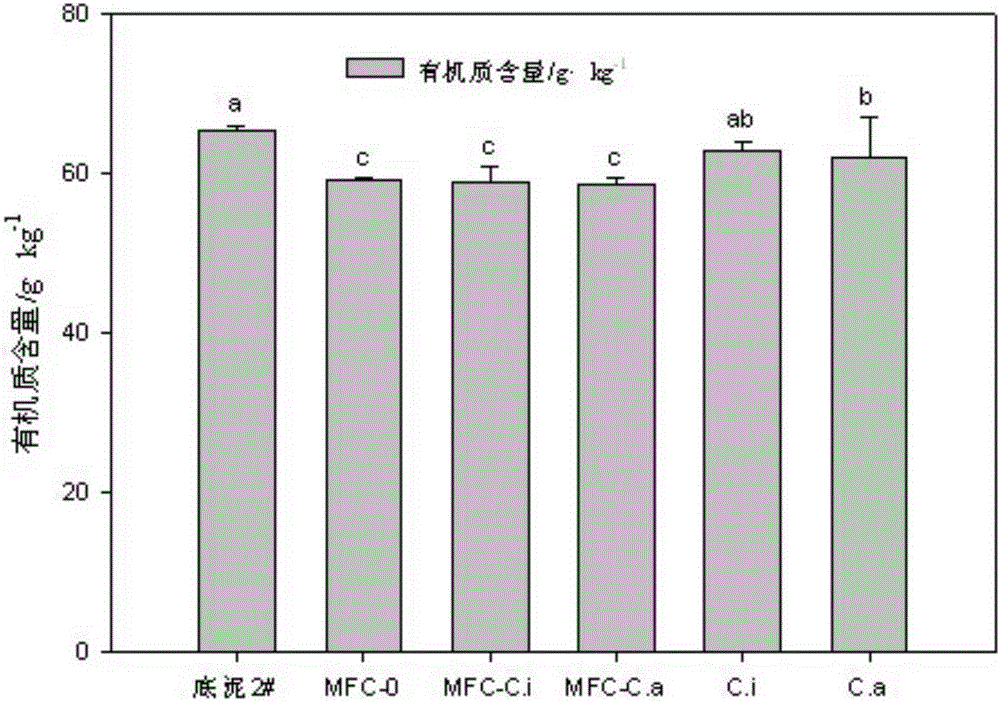

[0041] Embodiment 2P-SMFC electricity production consumes organic matter in the substrate

[0042] Sediment and biogas residues contain abundant microorganisms, which play an important role in the transformation of organic matter. They mainly decompose organic matter through oxidation, reduction, and hydrolysis, and then degrade organic matter through the extracellular enzymes secreted by them, or absorb organic matter into cells and degrade them by intracellular enzymes. In the MFC-0, MFC-C.i and MFC-C.a systems, the removal of organic matter mainly depends on the action of these microorganisms and the release to the overlying water; in addition to these two methods, the addition of electrodes will promote the decomposition of organic matter.

[0043] Such as image 3 , the change of organic matter content in the sediment of each system. It can be seen from the figure that after one month, the organic matter content of MFC-0, MFC-C.i and MFC-C.a decreased significantly, exc...

Embodiment 3

[0045] The variation of substrate ammonium nitrogen content in embodiment 3P-SMFC

[0046] Figure 5 It is the change diagram of ammonium nitrogen in the sediment of each treatment group. It can be seen that the ammonium nitrogen content in each treatment group was significantly lower than that of the sediment (P0.05), but the ammonium nitrogen content decreased The amount is slightly lower than that of MFC-0. Among the five treatment groups, the reduction of ammonium nitrogen in the pure plant system C.i and C.a was significantly higher than that of MFC-0, MFC-C.i and MFC-C.a (P0.05), the reductions of the five were 42.03±3.28%, 47.07±2.58%, 22.22±0.42%, 13.33±2.21% and 14.76±6.30%. There was no significant difference in the change of ammonium nitrogen content between the treatment group based on windmill grass and the treatment group based on canna under the conditions of electrode and no electrode (P>0.05).

[0047] In the P-SMFC system, the removal of organic matter and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com