Graphite felt watch surface modified method and modified mineral carbon felt

A surface modification, graphite felt technology, applied in electrode manufacturing, electrical components, circuits, etc., can solve the problem that there is no modification treatment method that can improve the water wettability and electrochemical activity of graphite felt at the same time, and the electrochemical performance of electrodes is not ideal. , poor electrochemical activity of graphite felt electrodes, etc., to achieve the effect of improving electrochemical activity, increasing stable discharge time, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

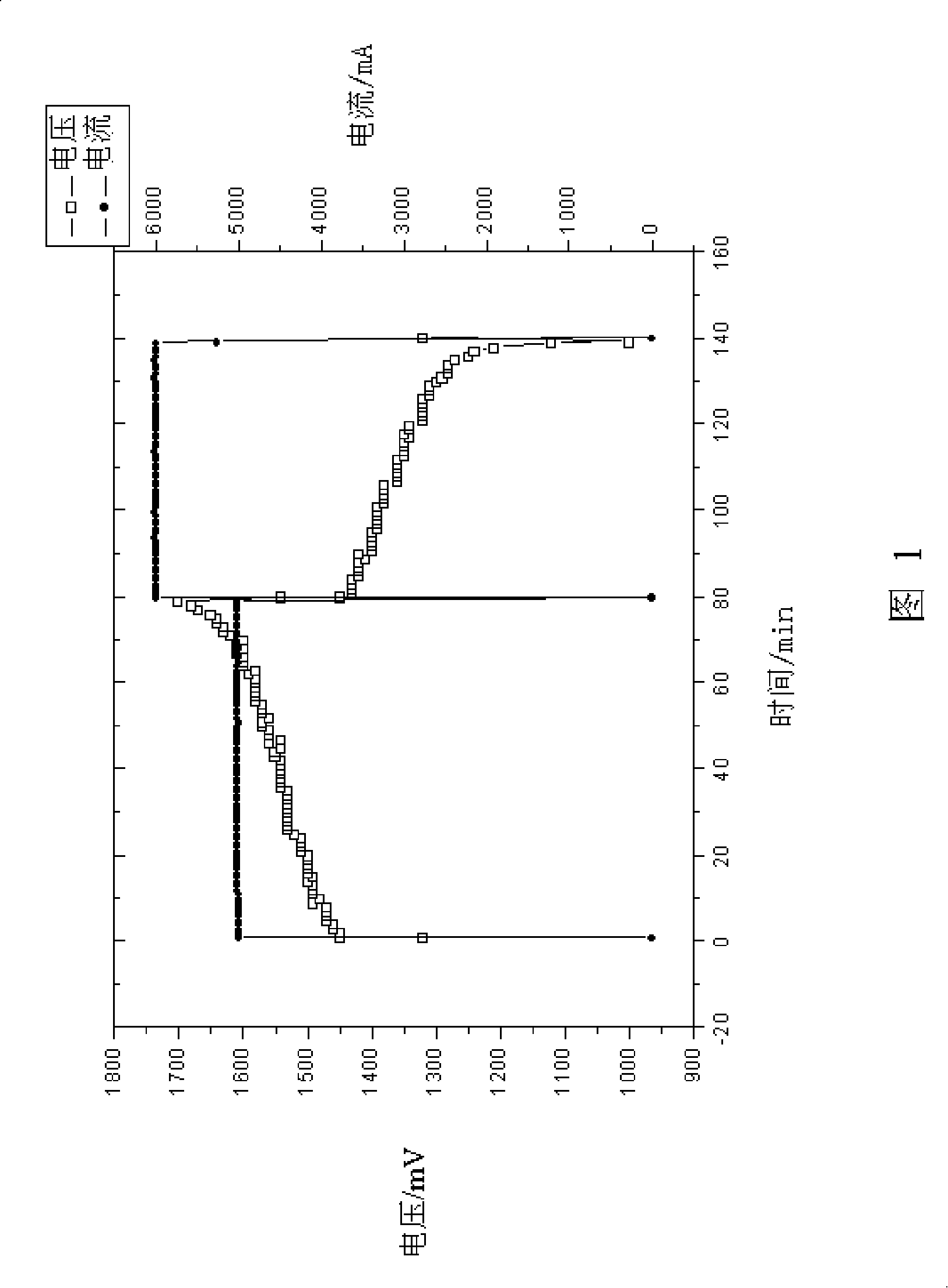

Embodiment 1

[0035] With graphite felt I as the cathode, NaOH and Na 2 CO 3 And the mixed solution of sodium lauryl sulfate is electrolyte, and electrolyte composition is sodium hydroxide 20g / l, sodium carbonate 20g / l, emulsifier 2g / l, and electrolyte temperature is 80 ℃; Electrochemical cathodic treatment with a current density of 75mA / cm 2 ; After 4 minutes, take it out for later use; use hot distilled water (70-80° C.) and distilled water to repeatedly clean the lye on the surface of the graphite felt. The graphite felt after electrochemical cathodic modification is used as the anode, 1M sulfuric acid solution is used as the electrolyte, the water bath is heated to 85°C, and the graphite felt is subjected to anodic oxidation modification by direct current, and the oxidation current density is 160mA / cm 2 , after the oxidation time of 4min, take it out for subsequent use; repeatedly clean the acid on the surface of the graphite felt with distilled water, and dry it to obtain the modifie...

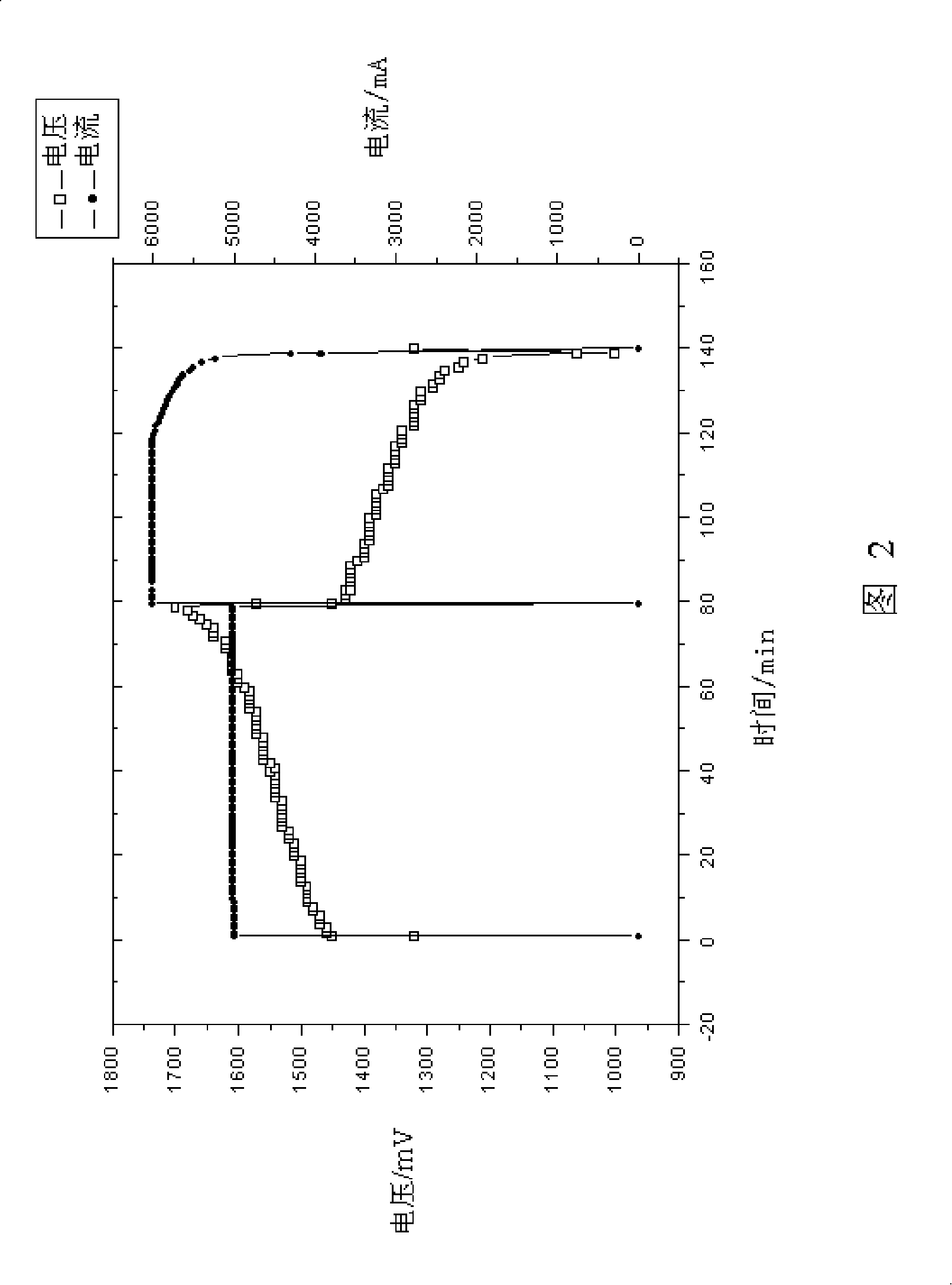

Embodiment 2

[0041] With graphite felt II as the cathode, NaOH and Na 2 CO 3 The mixed solution is an electrolyte solution, each concentration is 20g / L, and the temperature of the electrolyte solution is 50°C; the graphite felt is subjected to electrochemical cathode treatment by direct current, and the current density is 140mA / cm 2 ; After 8 minutes, take it out for use; wash the surface of the graphite felt repeatedly with hot distilled water (70-80°C) and distilled water in turn until the distilled water after cleaning is neutral. The graphite felt after electrochemical cathode modification is used as the anode, 1M sulfuric acid solution is used as the electrolyte, the water bath is heated to 90°C±1°C, and the graphite felt is subjected to anodic oxidation modification by direct current, and the oxidation current density is 160mA / cm 2 , after the oxidation time of 4min, take it out for subsequent use; repeatedly clean the surface of the graphite felt with distilled water until the clea...

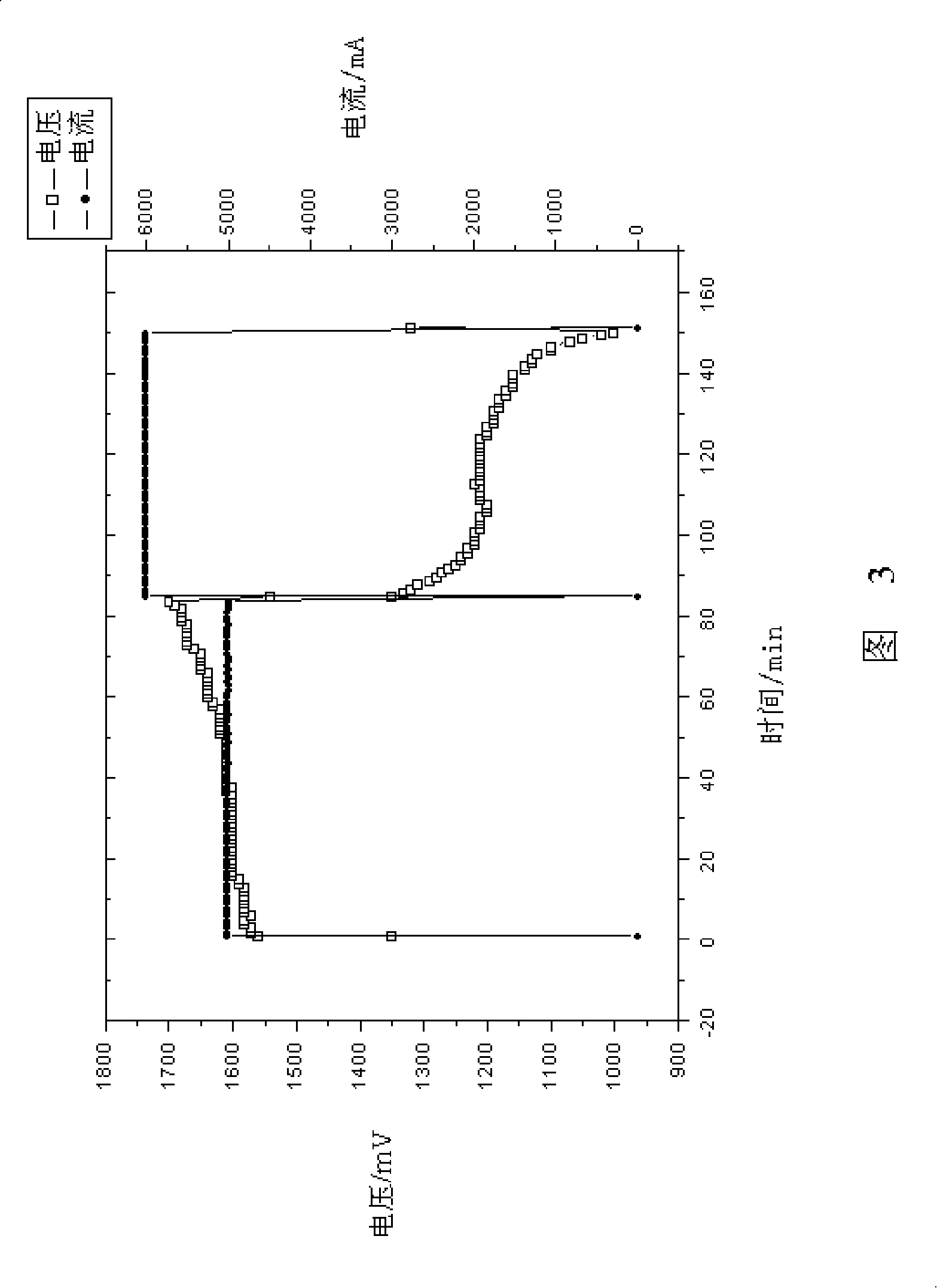

Embodiment 3

[0047] Graphite felt III is used as the cathode, NaOH solution is used as the electrolyte, the concentration is 40g / L, and the temperature of the electrolyte is 90°C; direct current is applied to the graphite felt for electrochemical cathode treatment, and the current density is 160mA / cm 2 ;Take it out after 10 minutes for later use; wash the graphite felt surface repeatedly with hot distilled water (70-80°C) and distilled water in turn until the distilled water after cleaning is neutral. The graphite felt after electrochemical cathodic modification is used as the anode, 1M sulfuric acid solution is used as the electrolyte, the water bath is heated to 85°C, and the graphite felt is subjected to anodic oxidation modification by direct current, and the oxidation current density is 160mA / cm 2 , after the oxidation time of 4min, it was taken out for subsequent use; the surface of the graphite felt was repeatedly cleaned with distilled water until the cleaned distilled water was neu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com