Bipolar plate of integrated composite electrode, and manufacturing method and application thereof

A composite electrode and bipolar plate technology, used in battery electrodes, circuits, fuel cells, etc., can solve the problems of electrical corrosion of conductive plastic bipolar plates, unstable structure, battery failure, etc., and achieve good mechanical properties and electrical conductivity. One-piece performance, easy-to-produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An integrated composite electrode bipolar plate, prepared by the following method:

[0030] (1) PE plastic granules are heated and extruded to form softened plastic sheets;

[0031] (2) Place two 5mm thick graphite felts on the inside of the mold A and B boards respectively, place the PE plastic sheet between the two graphite felts, and then close the mold tightly;

[0032] (3) Vacuum the inside of the mold;

[0033] (4) Treat the mold and the graphite felt and PE plastic sheet in the mold at a constant temperature of 160-170°C for 75-100 minutes, during which time the mold is extruded through an extruder, and the PE plastic sheet is completely dissolved in the graphite felt after treatment. After cooling, an integrated composite electrode bipolar plate is obtained.

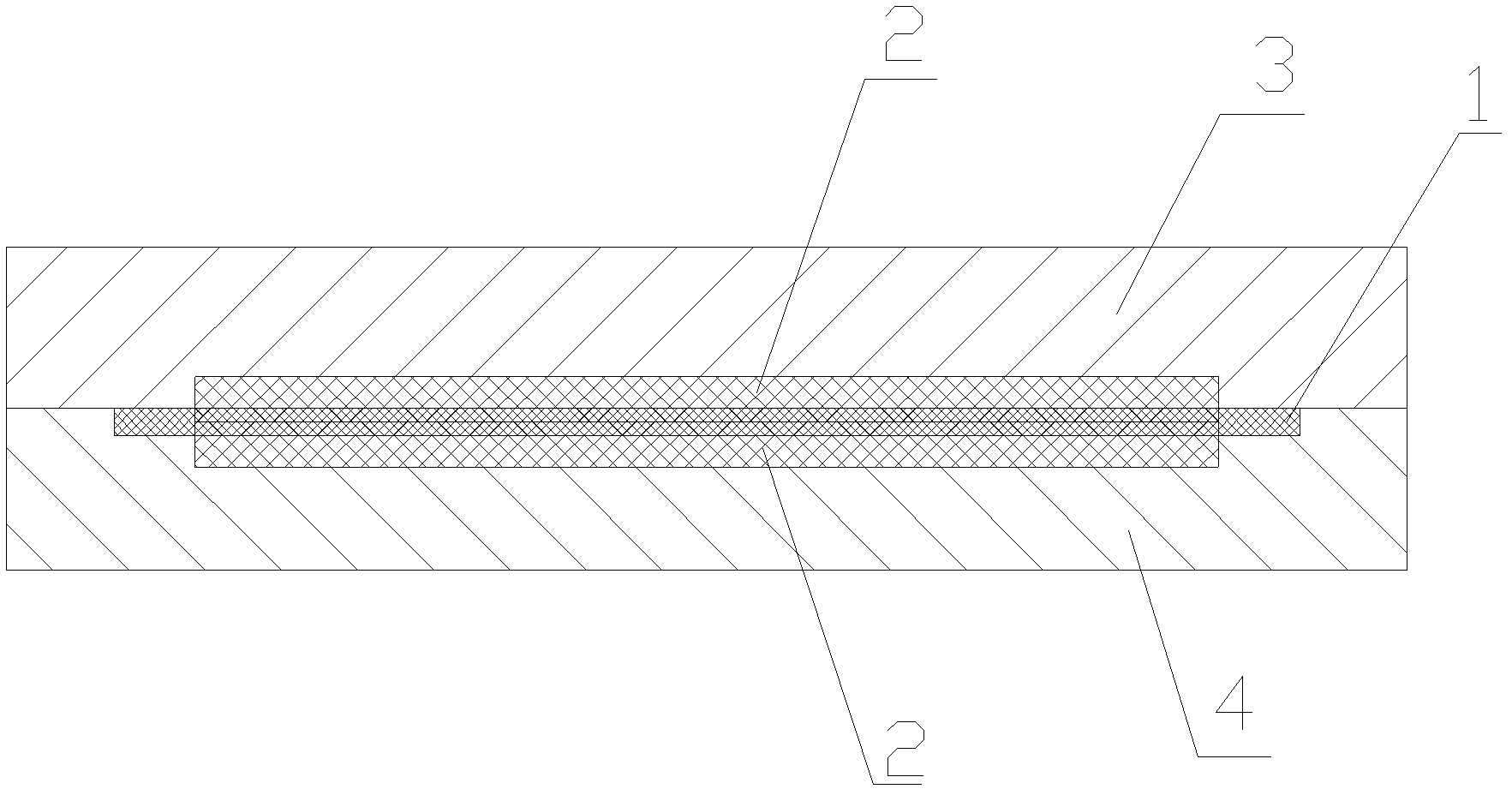

[0034] The structure of the prepared integrated composite electrode bipolar plate is as follows: figure 1 As shown, the graphite felt 2 and the PE plastic sheet 1 have been extruded and melted into one,...

Embodiment 2

[0036] An integrated composite electrode bipolar plate, prepared by the following method:

[0037] (1) PE plastic granules are heated and extruded to form softened plastic sheets;

[0038] (2) Place two 6mm thick carbon felts on the inner side of the mold A and B boards respectively, place the PE plastic sheet between the two carbon felts, and then close the mold tightly;

[0039] (3) Vacuum the inside of the mold;

[0040] (4) Treat the mold and the carbon felt and PE plastic sheet in the mold at a constant temperature of 180-190°C for 55-70 minutes, and extrude the mold through an extruder during this period. After the treatment, the PE plastic sheet is completely dissolved in the carbon felt. After cooling, an integrated composite electrode bipolar plate is obtained.

[0041] The structure of the prepared integrated composite electrode bipolar plate is as follows: figure 1As shown, the carbon felt 2 and the PE plastic sheet 1 have been extruded and melted into one, the p...

Embodiment 3

[0043] An integrated composite electrode bipolar plate, prepared by the following method:

[0044] (1) PE plastic granules are heated and extruded to form softened plastic sheets;

[0045] (2) Place two graphite felts with a thickness of 7mm on the inner side of mold A and plate B respectively, place the PE plastic sheet between the two graphite felts, and then close the mold tightly;

[0046] (3) Vacuum the inside of the mold;

[0047] (4) Treat the mold and the graphite felt and PE plastic sheet in the mold at a constant temperature of 200-210°C for 40-50 minutes, during which time the mold is extruded through an extruder, and the PE plastic sheet is completely dissolved in the graphite felt after treatment. After cooling, an integrated composite electrode bipolar plate is obtained.

[0048] The structure of the prepared integrated composite electrode bipolar plate is as follows: figure 1 As shown, the graphite felt 2 and the PE plastic sheet 1 have been extruded and melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com