Carbon/carbon heat screen of polysilicon hydrogenation furnace and manufacture method thereof

A technology of heat shield and polysilicon, applied in silicon and other directions, can solve the problems of inability to withstand the high pressure of the hydrogenation furnace, poor sealing performance of the heat shield, and difficult installation, etc., and achieve low ash content, good heat insulation performance, and reduced raw material consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

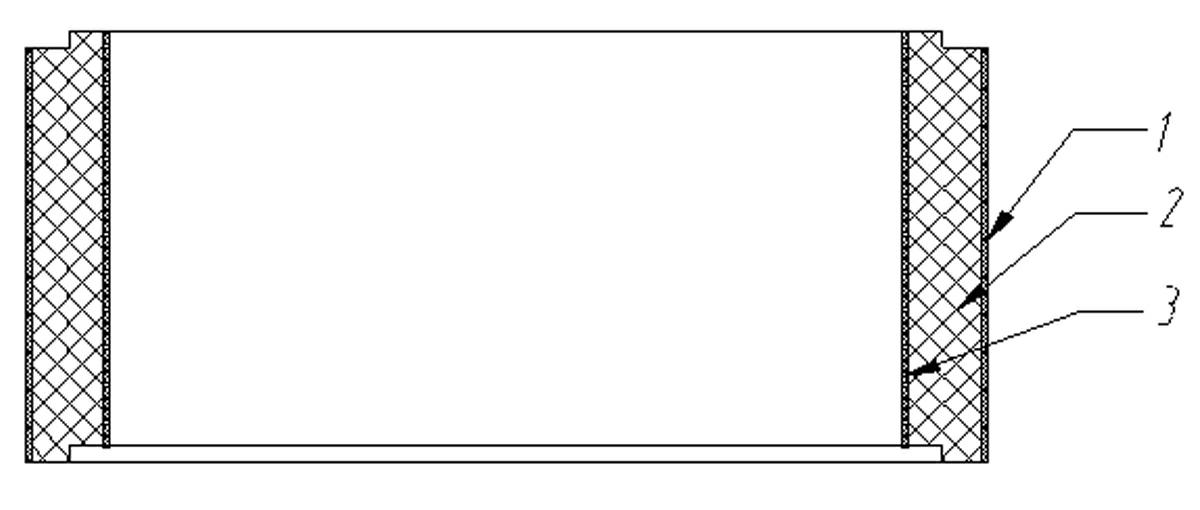

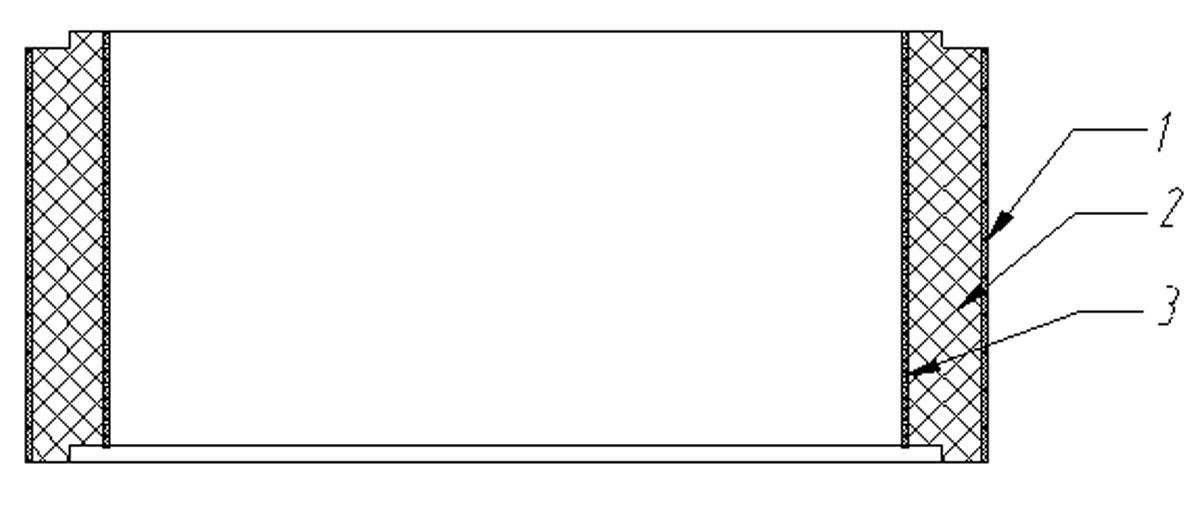

[0037] The carbon / carbon composite polysilicon hydrogenation furnace heat shield embodiment is a carbon / carbon composite polysilicon hydrogenation furnace heat shield with a diameter of 1595mm, a height of 727mm, and a thickness of 130mm; it is composed of a heat shield body and a silicon carbide protective layer, so For the body structure of the heat shield, see figure 1 , is a kind of "sandwich" structure, the outer layer 1 and inner layer 3 are densified by 6K carbon fiber cloth, the middle layer 2 of the heat shield is densified by soft carbon felt; the silicon carbide protective layer is covered on the heat shield body surface.

[0038] Its preparation method is as follows:

[0039] (1) Make a heat shield steel tire membrane with a diameter of 1338mm and a height of 800mm;

[0040] (2) After the 6K carbon fiber cloth is evenly coated with furan resin, wrap it layer by layer on the steel tire membrane. When the thickness of the wrapping reaches 5mm, then wrap the soft ca...

Embodiment 2

[0052] (1) Make a heat shield steel tire membrane with a diameter of 1680mm and a height of 950mm;

[0053] (2) After the carbon fiber cloth is evenly coated with furan resin, wrap it layer by layer on the steel tire membrane. When the thickness of the wrapping reaches 4mm, then wrap the soft carbon felt soaked with furan resin layer by layer. When the thickness reaches 1808mm, the carbon fiber cloth evenly coated with furan resin is wound on the soft carbon felt layer by layer. When the overall thickness of the winding is equal to 1810mm, the winding process is completed, and then the external force is used to compact it to form a kind of "sandwich sandwich". ” structure of the heat shield body blank;

[0054] (3) Put the heat shield body blank obtained in step (3) together with the steel tire film into an oven for curing, the treatment time is 320 minutes, and the curing temperature is 180°C to obtain a heat shield body blank;

[0055] (4) Put the heat shield body blank wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com