System and method for preparing graphene by means of SiC thermal cracking

A graphene and thermal cracking technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of affecting the growth quality of graphene, the SiC surface is easily polluted, and the MBE system cannot achieve etching and growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

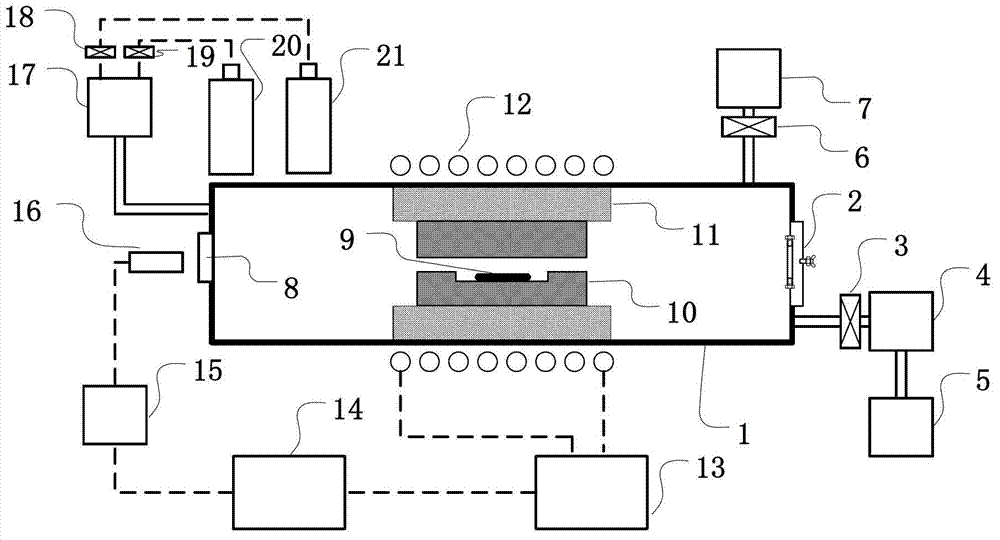

[0021] Attached below figure 1 and specific examples to further illustrate specific embodiments of the present invention.

[0022] The system for preparing graphene by SiC pyrolysis method includes a gas-refined quartz tube 1 as a vacuum chamber, a SiC substrate 9 located in the middle of the vacuum chamber, an induction heating graphite boat 10 and a carbon felt insulation layer 11. The SiC substrate 9 is located in the sample chamber of the graphite boat 10, the graphite boat is located in the middle of the carbon felt insulation layer 11, and the carbon felt insulation layer 11 is close to the tube wall of the vacuum chamber and forms a hollow structure;

[0023] One end of the vacuum chamber body has a vacuum chamber door 2 for opening and closing the vacuum chamber body. Below the vacuum chamber door 2, a vacuum chamber composed of a damper valve 3, a molecular pump 4 and a mechanical pump 5 is sequentially connected. The road is used to evacuate the vacuum cavity as nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com