Single-cell-thickness nano porous cobalt oxide nanosheet array electrocatalytic material

A technology of cobalt trioxide nanometer and electrocatalytic materials, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc. It can solve the problems affecting popularization and application, poor HER performance, etc., and achieve the effects of environmental friendliness, convenient operation and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

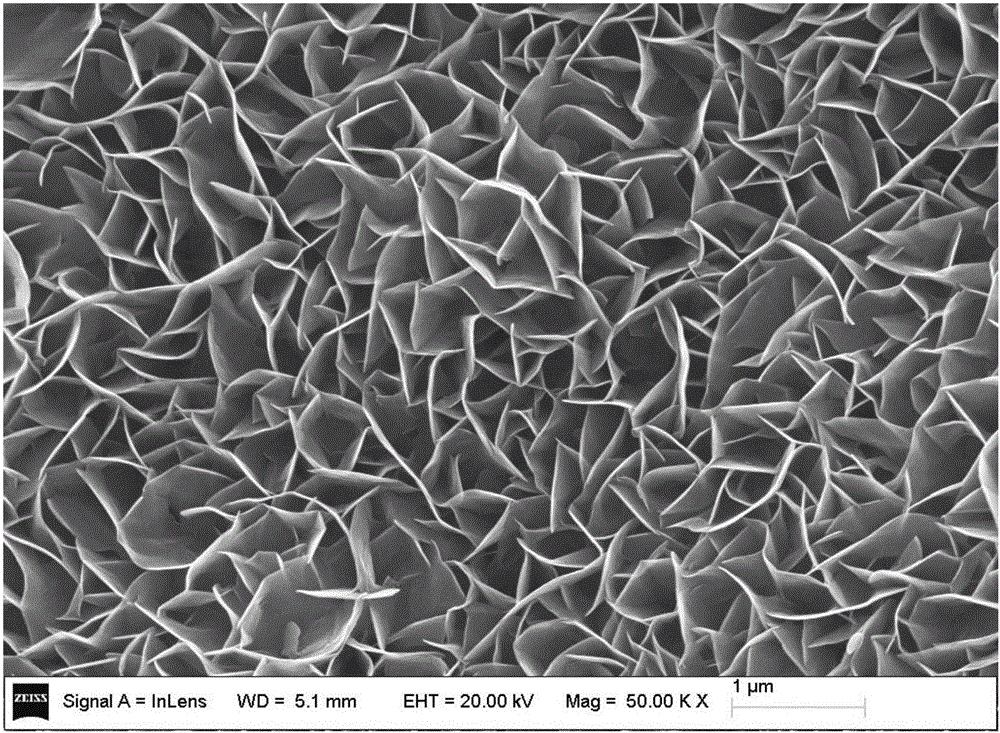

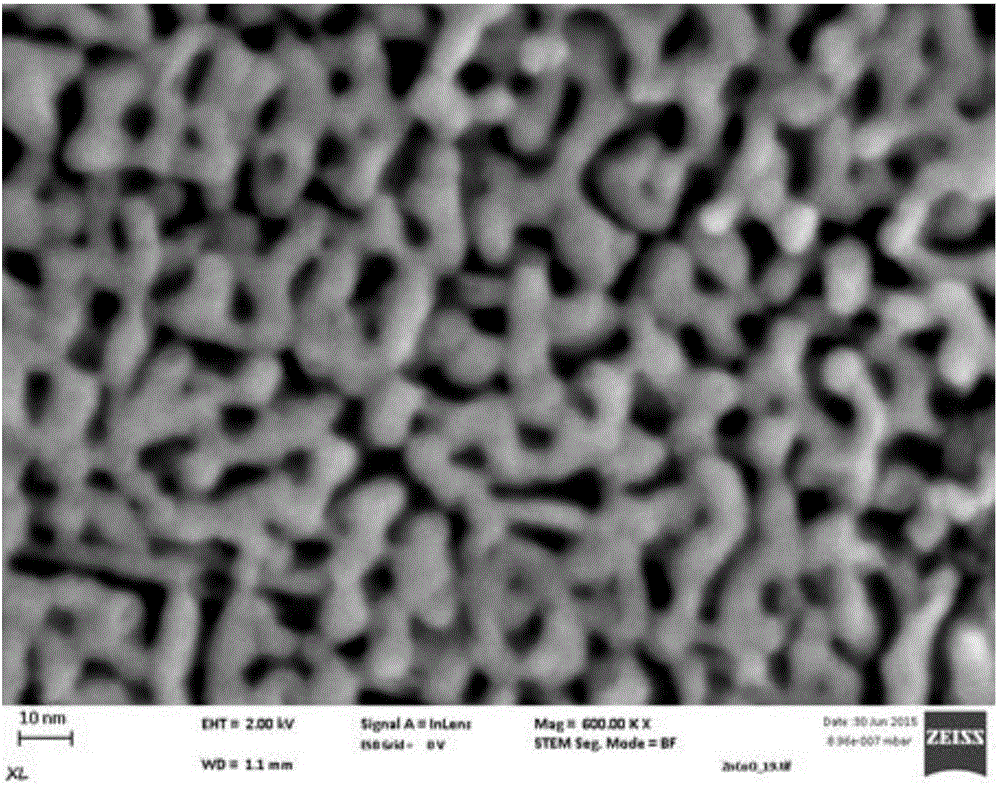

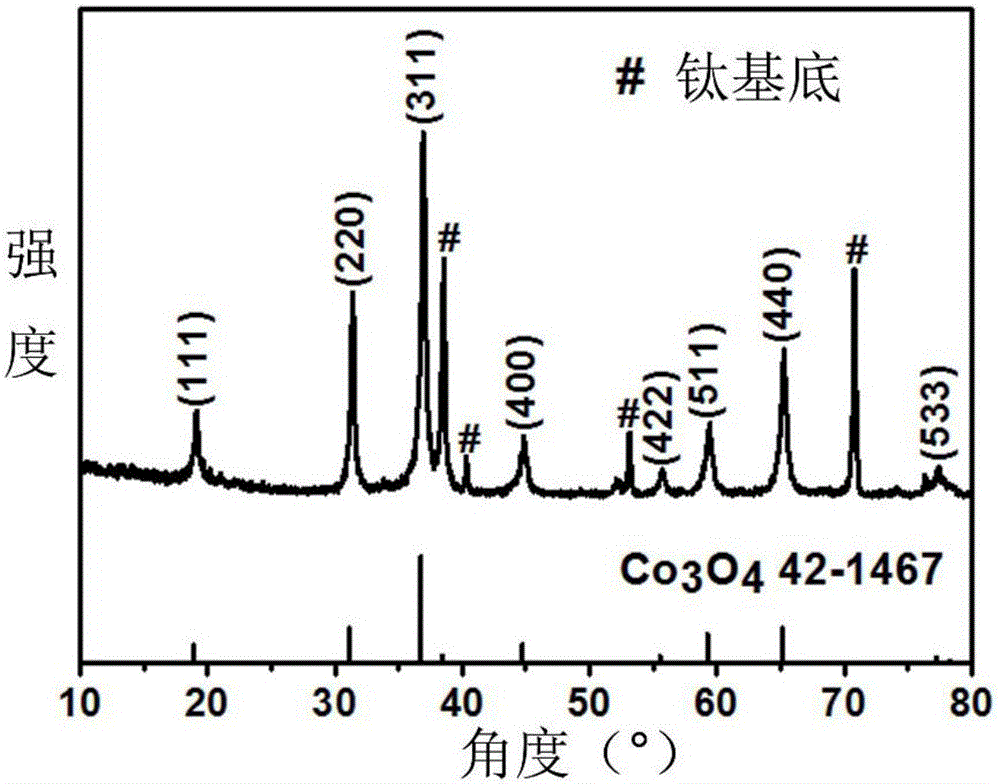

[0037] A nanoporous cobalt tetraoxide nanosheet array electrocatalytic material with a unit cell thickness, which is a zinc-doped cobalt tetraoxide primary nanosheet array grown on a conductive substrate perpendicular to the substrate, each of the primary nanosheets is obtained with a unit cell thickness Nanoporous cobalt tetroxide nanosheets, the conductive substrate is a titanium sheet, the doped metal is zinc, and the molar ratio of the doped metal to cobalt is 0.5:1; the thickness of the metal-doped cobalt trioxide ultrathin nanosheets is 0.84nm, Has a nanoporous structure.

[0038] The preparation method of the nanoporous cobalt tetraoxide nanosheet array electrocatalytic material with unit cell thickness comprises the following steps:

[0039] 1) Prepare the first aqueous solution of hydrochloric acid with a concentration of 1 mol / liter, put the conductive substrate into the hydrochloric acid solution and ultrasonically clean it for 5 minutes, then put the conductive sub...

Embodiment 2

[0050] A nanoporous cobalt tetraoxide nanosheet array electrocatalytic material with different thicknesses is a zinc-doped cobalt tetraoxide primary nanosheet array grown perpendicular to the substrate on a conductive substrate, and each primary nanosheet is obtained with different thicknesses. In the nanoporous cobalt trioxide nanosheet, the conductive substrate is a titanium sheet, the doped metal is zinc, and the molar ratio of zinc to cobalt is 0.5:1.

[0051] The preparation method of the electrocatalytic material is basically the same as that of Example 1, except that the soaking time in step 3 in the sodium hydroxide alkali solution containing sodium borohydride is changed. The immersion times were 1 h, 1.5 h, 2.5 h, and 3 h, and the obtained materials were named NPCoO-1h-NSs, NPCoO-1.5h-NSs, NPCoO-2.5h-NSs, and CoO-3h-Ps, respectively.

[0052] Figure 7 It is the scanning electron micrograph (SEM), transmission electron micrograph (TEM) and atomic force micrograph (A...

Embodiment 3

[0055] A nanoporous cobalt tetraoxide nanosheet array electrocatalytic material with a unit cell thickness, which is a metal-doped cobalt tetraoxide primary nanosheet array grown on a conductive substrate perpendicular to the substrate, each of the primary nanosheets is obtained with a unit cell thick nanoporous cobalt trioxide nanosheets, the conductive substrate is titanium sheet, the doped metal is zinc, and the molar ratio of zinc to cobalt is 0.2:1.

[0056] The preparation method of the electrocatalytic material is basically the same as in Example 1, except that the concentration of zinc nitrate in step 2 is changed.

[0057] The preparation method of the electrocatalytic material is the same as that of Example 1. The obtained material is similar to the material obtained in Example 1 in appearance and performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com