A cobalt monoatomic catalyst with cobalt atoms anchored on carbon nanofibers and a preparation method and application thereof

A technology of carbon nanofibers and atomic anchors, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high cost and poor OER catalytic performance, and achieve easy operation, good ORR and OER catalytic performance, and excellent methanol resistance effects on receptivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

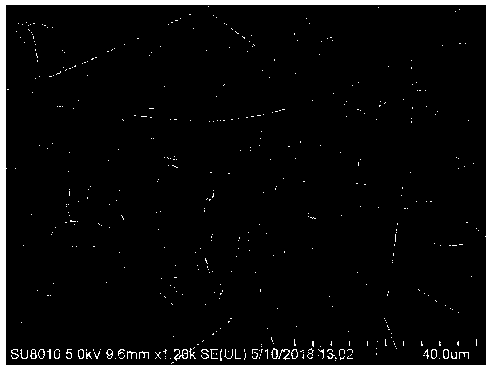

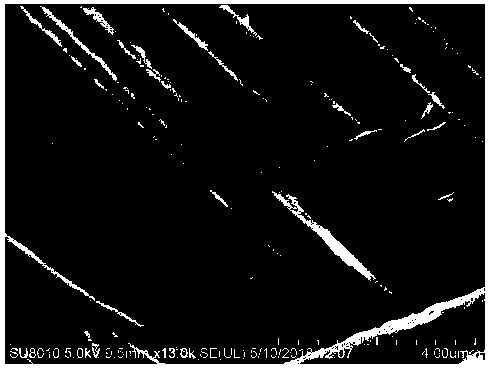

[0052] This example provides cobalt single atom Co-N anchored on carbon nanofibers with cobalt atoms 4 The CNFs catalyst is prepared by the following method.

[0053] Weigh 0.1 g of cobalt acetylacetonate, 0.2 g of m-tetraphenylporphine complexing agent and 0.4 g of polyacrylonitrile polymer dissolved in 4 g of N,N-dimethylformamide solvent for external solution, and weigh Take 0.5 g of polyethylene oxide polymer dissolved in 5 g of N,N-dimethylformamide solvent for internal solution.

[0054] The two solutions were vigorously stirred at 70°C for 8 h until they were completely dissolved, and the two viscous solutions were sucked into a syringe to implement the coaxial electrospinning process. During the electrospinning process, the inner diameter and outer diameter of the same spinneret were selected as 0.35 mm and 1.05 mm respectively, and the coaxial spinneret was adjusted so that the distance from the needle of the spinneret to the collector was 12 cm, and kept A voltage...

Embodiment 2

[0062] This example provides cobalt single atom Co-N anchored on carbon nanofibers with cobalt atoms 4 The CNFs catalyst is prepared by the following method.

[0063] Weigh 0.1 g of cobalt nitrate, 0.1 g of ethylenediaminetetraacetic acid complexing agent and 0.2 g of polyvinylpyrrolidone polymer dissolved in 2 g of isopropanol solvent for external solution, and weigh 0.5 g of polyethylene oxide polymer Dissolve in 2.5 g isopropanol for internal solution.

[0064] The two solutions were vigorously stirred at 80°C for 12 h until they were completely dissolved, and the two viscous solutions were sucked into syringes to implement the coaxial electrospinning process. During the electrospinning process, the inner diameter and outer diameter of the same spinneret were selected as 0.41 mm and 1.25 mm respectively, and the coaxial spinneret was adjusted so that the distance from the needle of the spinneret to the collector was 10 cm, and kept A voltage of 20 kV was applied while co...

Embodiment 3

[0068] This example provides cobalt single atom Co-N anchored on carbon nanofibers with cobalt atoms 4 The CNFs catalyst is prepared by the following method.

[0069] Weigh 0.1 g of cobalt chloride, 0.15 g of o-phenanthroline complexing agent and 0.3 g of styrene-acrylonitrile copolymer polymer dissolved in 3 g of dichloromethane solvent for external solution, while weighing 0.5 g of poly Acrylonitrile polymer was dissolved in 3 g of dichloromethane solvent for internal solution.

[0070] The two solutions were vigorously stirred at 90°C for 12 h until they were completely dissolved, and the two viscous solutions were sucked into syringes to implement the coaxial electrospinning process. During the electrospinning process, the inner diameter and outer diameter of the same spinneret were selected as 0.45 mm and 1.35 mm respectively, and the coaxial spinneret was adjusted so that the distance from the needle of the spinneret to the collector was 15 cm, and kept A voltage of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com